Method for preparing oxygen vacancy type metal oxide with controllable acid etching effect

A technology of oxides and oxygen vacancies, which is applied in the direction of cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., can solve the problems of difficult to effectively and accurately control the concentration of oxygen vacancies in manufacturing, difficult to recycle waste materials, and high operating risk factors. Achieve the effects of low cost, wide application range and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare a hydrochloric acid solution with a concentration of 4 M and a volume of 20 mL, and add 40 mg of commercial Co 3 o 4 (purchased from Shanghai Macklin Biochemical Technology Co., Ltd.), the obtained mixed solution was acid-etched at 25 °C for 24 h, and then the reaction solution was subjected to high-speed centrifugation at a speed of 4000 r / min to obtain solid components, and then passed through The oxygen vacancy type cobalt tetroxide (Co 3 o 4 –V o –4–24).

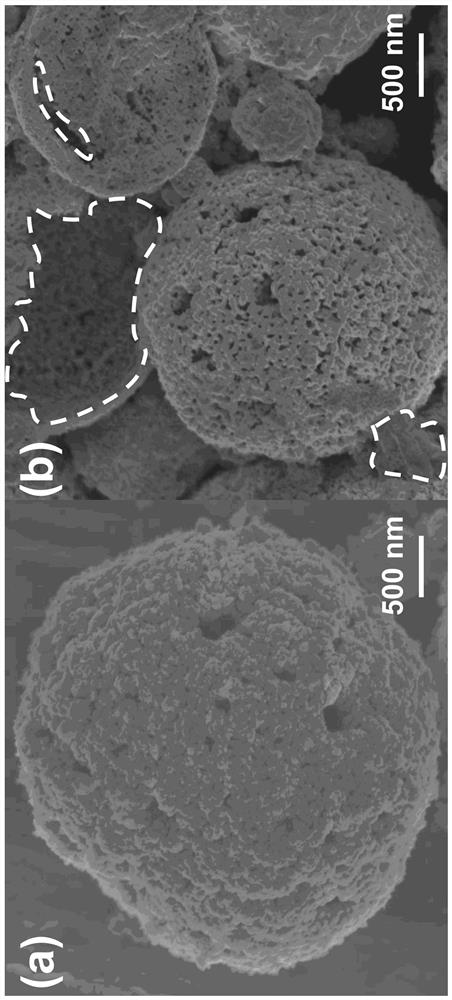

[0040] refer to figure 1 , as shown for the commercial pristine Co 3 o 4 and Co 3 o 4 –V o SEM images of –4–24. It can be seen from the figure that both samples exhibit a spherical structure assembled by a large number of nanoparticles. compared to pristine Co 3 o 4 ,Co 3 o 4 –V o The spherical structure of –4–24 was partially acid-etched to form local holes (as indicated by the white dotted line box in the figure).

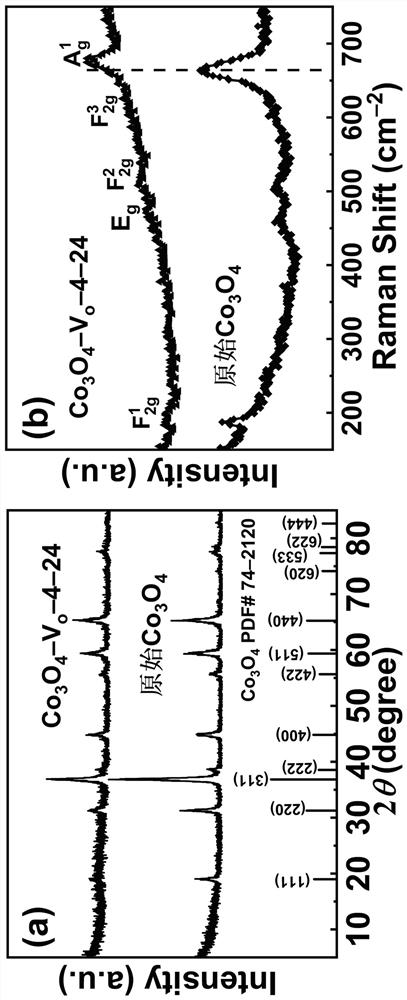

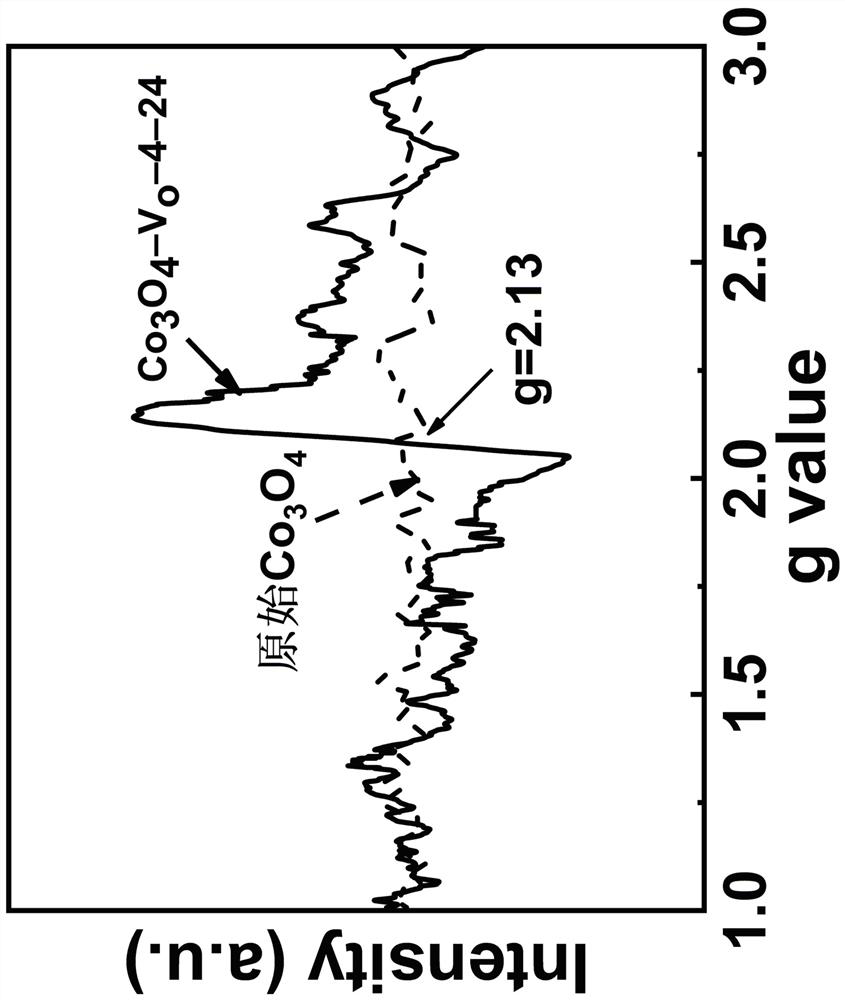

[0041] refer to figure 2 , as shown for the commercial pristine Co 3 ...

Embodiment 2

[0045] Prepare two hydrochloric acid solutions with a concentration of 6 M and a volume of 24 mL, and add 40 mg of commercial Co 3 o 4 , the resulting mixture was acid-etched at 25 °C for 6 h and 54 h, and then the resulting reaction liquid was subjected to high-speed centrifugation at a speed of 6000 r / min to obtain a solid component, which was passed through deionized water and anhydrous After repeated washing with ethanol for 3 times and drying in a vacuum oven at 60 °C for 12 h, two different oxygen vacancy types of cobalt tetroxide (labeled as Co 3 o 4 –V o –6–6 and Co 3 o 4 –V o –6–54).

[0046] refer to Figure 5 , as shown for the commercial pristine Co 3 o 4 、Co 3 o 4 –V o –6–6 and Co 3 o 4 –V o XRD (a) and Raman (b) spectra of –6–54. It can be seen from figure (a) that the three samples are at 2 θ = 31.3°, 36.8°, 44.8°, 59.4° and 65.2° where typical Co 3 o 4 characteristic diffraction peaks, indicating that the acid etching treatment does not chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com