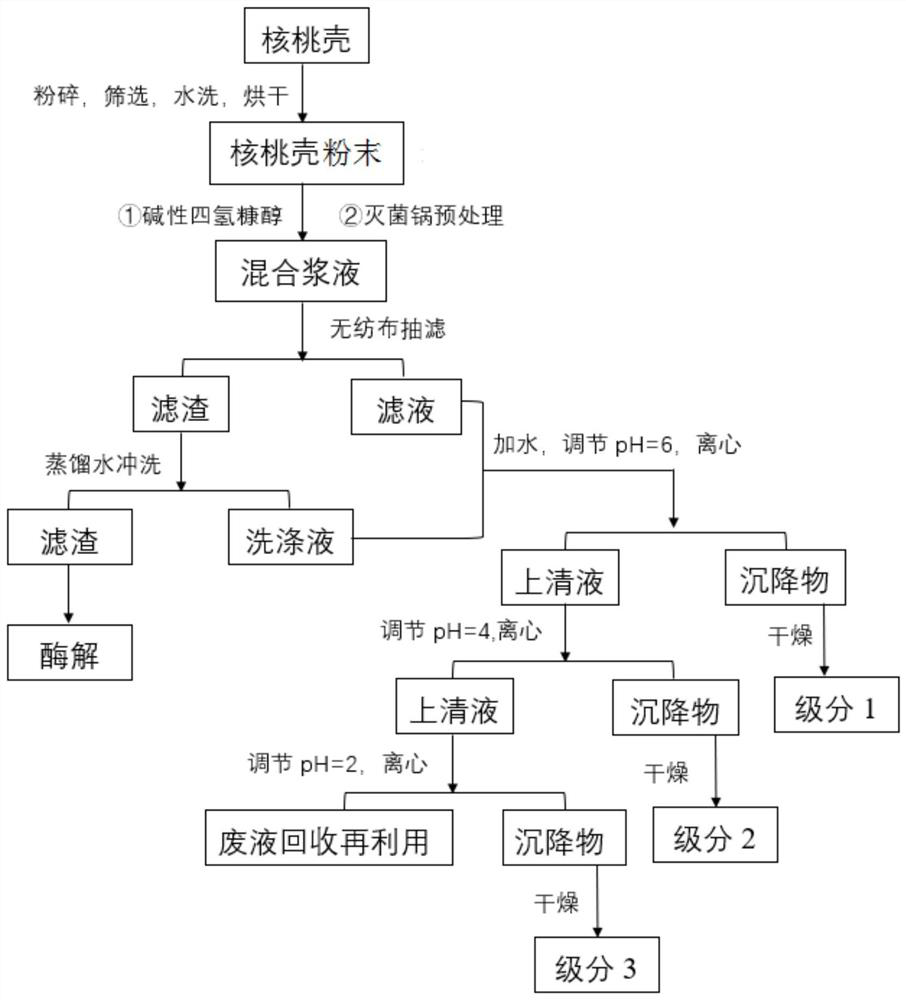

Method for extracting low-molecular-weight lignin from walnut shells through graded sedimentation of alkaline tetrahydrofurfuryl alcohol

A tetrahydrofurfuryl alcohol and low molecular weight technology is applied in the fields of biomass pretreatment and comprehensive utilization of agricultural wastes, which can solve the problems of lignin dissolution rate and lignin purity, molecular weight and dispersibility need to be improved, and achieves a simple pretreatment method. The effect of convenience, simple steps and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After the walnut shells are crushed, sieved, washed and dried, take 400g as the raw material for biomass pretreatment, divide it into 4 parts and transfer them to 1000mL blue cap bottles respectively, and add them according to the solid-liquid ratio of 1:5 500ml of 5% alkaline tetrahydrofurfuryl alcohol solution (w / w), then put into a sterilizer for reaction, the reaction temperature is 135°C, and the reaction time is 90min. After the pretreatment, after the non-woven fabric decompression suction filtration, take out the filtrate of 1000ml in the beaker, and add 3 times of volumes of water to dilute the organic solvent, then slowly adjust the pH to 6, a part of lignin (lignin fraction II) Settling out first, the filtrate is collected and adjusted to pH=4, another part of lignin (lignin fraction II) is settled out, the filtrate is collected, and its pH is adjusted to 2, and the last part of lignin (lignin fraction II) is settled out Lignin fraction III), after centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com