Heavy-duty anti-corrosion environment-friendly water-based industrial coating and preparation method thereof

A heavy anti-corrosion, water-based technology, applied in the field of coatings, can solve the problems of poor anti-corrosion performance, affect the aesthetics, and affect the anti-corrosion performance of industrial facilities, etc., achieve strong anti-corrosion performance and shrinkage performance, improve environmental protection, improve curing effect and The effect of salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of described waterborne epoxy A component comprises the following steps:

[0030] 1) A ring-opening reaction occurs using epoxy resin, polyethylene glycol diglycidyl ether and ethanolamine;

[0031] 2) Obtain reactive water-based epoxy emulsifier after neutralizing with glacial acetic acid again;

[0032] 3) The group in the emulsifier molecule was analyzed by infrared and the epoxy equivalent of the emulsifier was calculated to be 618g / mol according to the peak area at the epoxy characteristic absorption peak;

[0033] 4) Test the basic performance parameters of the emulsifier. The Krafft point of the emulsifier is 56°C, and the HLB value is about 16;

[0034] 5) Emulsifying the novolac epoxy resin NPPN631 with the above-mentioned water-based epoxy emulsifier to obtain a water-based epoxy emulsion.

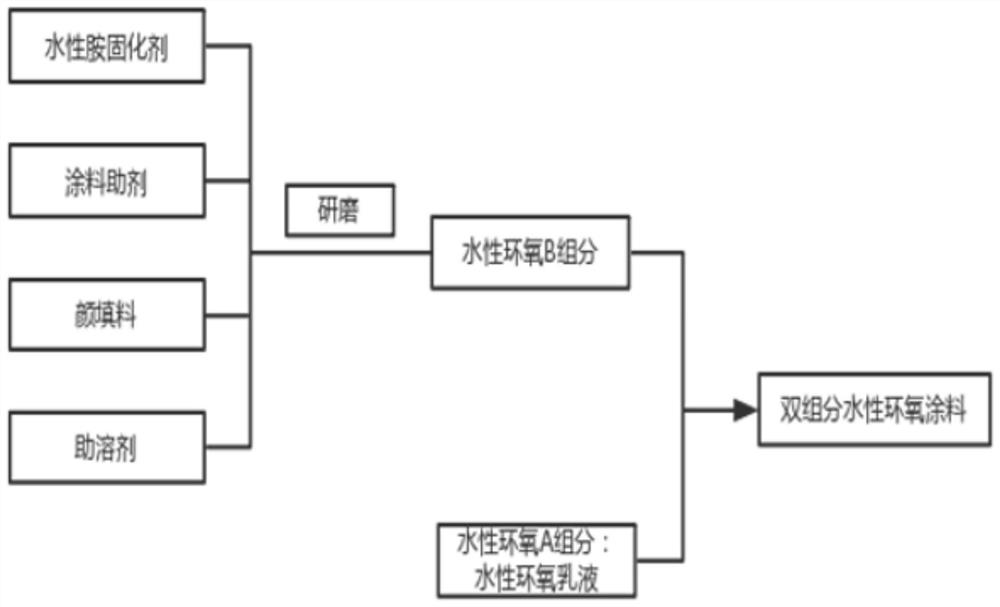

[0035] A kind of preparation method of heavy-duty anti-corrosion coating environment-friendly water-based industrial coating comprises the followi...

Embodiment 2

[0041] A kind of heavy-duty anti-corrosion coating environment-friendly water-based industrial paint, it comprises two-component water-based epoxy primer and water-based acrylic polyurethane paint topcoat, the top surface of described two-component water-based epoxy primer is coated with water-based acrylic polyurethane paint surface The two-component waterborne epoxy primer is composed of waterborne epoxy A component and waterborne epoxy B component.

[0042] The water-based epoxy A component is a water-based epoxy emulsion.

[0043] The water-based epoxy B component includes the following raw materials in parts by mass: 2.4 parts of water-based amine curing agent, 1.2 parts of coating additives, 2.0 parts of pigments and fillers and 3.0 parts of co-solvent.

[0044] The preparation method of described waterborne epoxy A component comprises the following steps:

[0045] 1) A ring-opening reaction occurs using epoxy resin, polyethylene glycol diglycidyl ether and ethanolamine...

Embodiment 3

[0056] A kind of heavy-duty anti-corrosion coating environment-friendly water-based industrial paint, it comprises two-component water-based epoxy primer and water-based acrylic polyurethane paint topcoat, the top surface of described two-component water-based epoxy primer is coated with water-based acrylic polyurethane paint surface The two-component waterborne epoxy primer is composed of waterborne epoxy A component and waterborne epoxy B component.

[0057] The water-based epoxy A component is a water-based epoxy emulsion.

[0058] The water-based epoxy B component includes the following raw materials in parts by mass: 1.8 parts of water-based amine curing agent, 1.0 parts of coating additives, 1.5 parts of pigments and fillers and 2.25 parts of co-solvent.

[0059] The preparation method of described waterborne epoxy A component comprises the following steps:

[0060] 1) A ring-opening reaction occurs using epoxy resin, polyethylene glycol diglycidyl ether and ethanolamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Krafft point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com