Diesel oil anti-wear agent with excellent comprehensive performance and preparation method thereof

A technology of comprehensive performance and anti-wear agent, applied in the field of diesel anti-wear agent and its preparation, can solve the problems of reducing the acid value of diesel anti-wear agent, reducing the anti-wear effect of the anti-wear agent, and reducing the freezing point of the anti-wear agent. Value reduction, reduction of separation steps, effect of mitigating reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

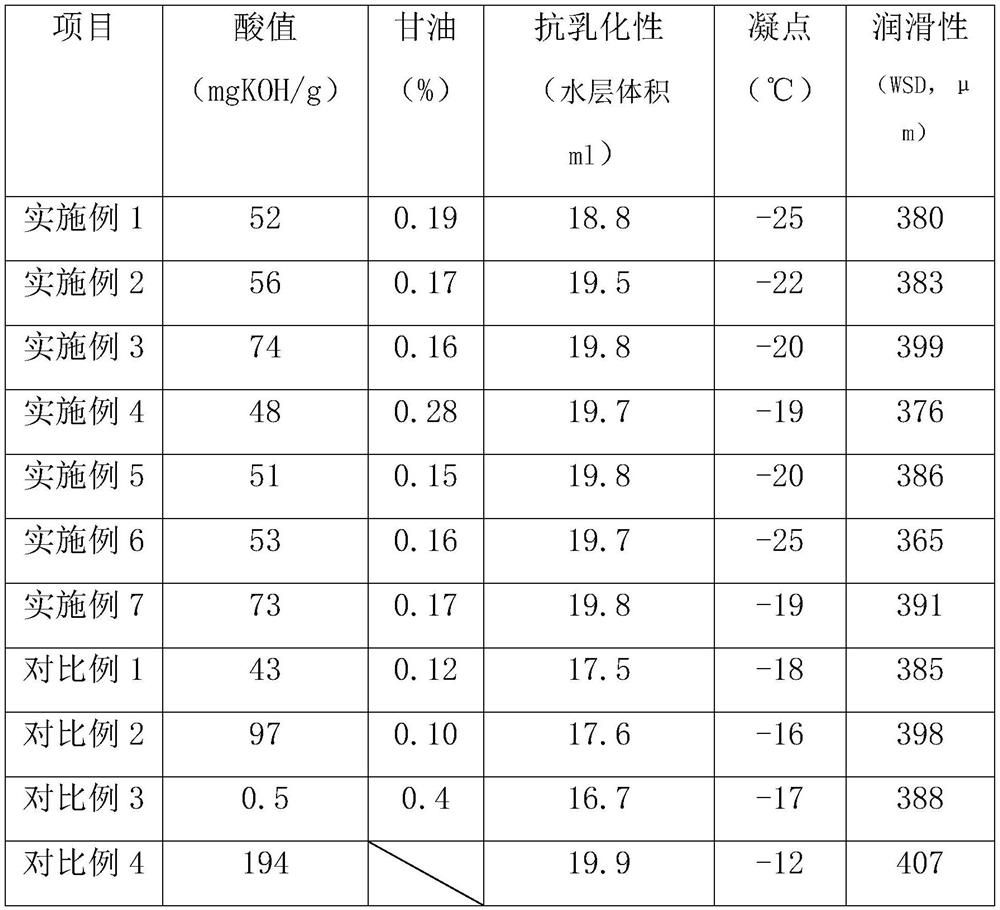

Embodiment 1

[0036] S1, weigh 0.35kg of glycerin and add it to the esterification reaction kettle, then weigh 0.03kg of strong acid resin and add it to the glycerin, and add 0.27kg of xylene water-carrying agent and 0.55kg of oleic acid, in a nitrogen environment Start stirring, and heat the above mixture to 140°C for esterification reaction for 6h;

[0037] S2, after the esterification reaction is completed, the temperature is lowered to 60°C, and the xylene-carrying agent is extracted and removed under reduced pressure;

[0038] S3, the product in S2 is filtered to remove the strong acidic resin;

[0039] S4, cooling the product in S3 to 25° C., and removing residual moisture and impurities therein by molecular sieve refining;

[0040] S5, add 0.002 kg of anti-emulsifier, 0.03 kg of pour point depressant and 0.005 kg of antistatic agent to the product obtained in S4, and stir and mix thoroughly for 15 minutes to obtain a diesel antiwear agent.

Embodiment 2

[0042] S1, weigh 0.35kg of glycerin and add it to the esterification reaction kettle, then weigh 0.04kg of strong acid resin and add it to the glycerin, and add 0.3kg of xylene water-carrying agent and 0.75kg of oleic acid, in a nitrogen environment Start stirring, and heat the above mixture to 140°C for 5.5 hours of esterification reaction;

[0043] S2, after the esterification reaction is completed, the temperature is lowered to 60°C, and the xylene-carrying agent is extracted and removed under reduced pressure;

[0044] S3, the product in S2 is filtered to remove the strong acidic resin;

[0045] S4, cooling the product in S3 to 25° C., and removing residual moisture and impurities therein by molecular sieve refining;

[0046] S5, add 0.006 kg of anti-emulsifier, 0.03 kg of pour point depressant and 0.008 kg of antistatic agent to the product obtained in S4, and stir and mix thoroughly for 15 minutes to obtain a diesel antiwear agent.

Embodiment 3

[0048]S1, weigh 0.35kg of glycerin and add it to the esterification reaction kettle, then weigh 0.04kg of strong acid resin and add it to the glycerin, and add 0.4kg of xylene water-carrying agent and 0.95kg of oleic acid, in a nitrogen environment Start stirring, and heat the above mixture to 140°C, and carry out esterification reaction for 5h;

[0049] S2, after the esterification reaction is completed, the temperature is lowered to 60°C, and the xylene-carrying agent is extracted and removed under reduced pressure;

[0050] S3, the product in S2 is filtered to remove the strong acidic resin;

[0051] S4, cooling the product in S3 to 25° C., and removing residual moisture and impurities therein by molecular sieve refining;

[0052] S5, add 0.01kg of anti-emulsifier, 0.04kg of pour point depressant and 0.012kg of antistatic agent to the product obtained in S4, and stir and mix thoroughly for 15 minutes to obtain a diesel antiwear agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com