A kind of high toughness tooth circular cutter processing technology

A processing technology and high toughness technology, applied in the field of tooth circular insert processing, can solve the problems of insufficient tooth circular insert toughness, reduced overall practicability, insufficient wear resistance, etc., to improve the rearrangement rate, eliminate residual stress, structural state stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

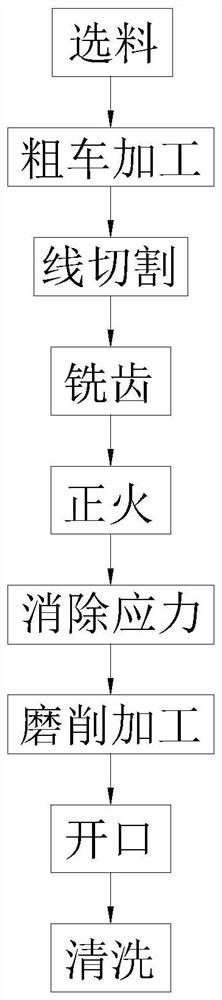

[0035] see figure 1 , the present invention discloses a kind of high toughness tooth circular cutter processing technology, and its processing technology is as follows:

[0036] Step 1: Select materials, select 65Mn spring steel, the impurity content on the surface and inside of the steel does not exceed 1%, and select a batch of high-quality spring steel raw materials to keep the same specifications;

[0037] Step 2: Rough turning, use an ordinary horizontal lathe to rough the toothed blade, first select a suitable fixture to clamp the outer circle, the plane at one end of the car is bright, cut the inner hole to the specified size, and leave 20- 30 wire allowance, then remove it, use a small hammer to lightly tap its center, remove the excess material, select a suitable boring tool to grind it; then select a suitable fixture to clamp the inner circle, turn it The thickness of the other end reaches the specified size; the tooling fixture continues to clamp the outer circle a...

Embodiment 2

[0051] The invention discloses a high-toughness tooth circular cutter processing technology, and the processing technology is as follows:

[0052] Step 1: Select materials, select 55SiCr spring steel, the impurity content on the surface and inside of the steel does not exceed 1%, and ensure that the selected high-quality steel raw material specifications are consistent;

[0053] Step 2: Rough turning, use an ordinary horizontal lathe to rough the toothed blade, first select a suitable fixture to clamp the outer circle, the plane at one end of the car is bright, cut the inner hole to the specified size, and leave 20- 30 wire allowance, then remove it, use a small hammer to lightly tap its center, remove the excess material, select a suitable boring tool to grind it; then select a suitable fixture to clamp the inner circle, turn it The thickness of the other end reaches the specified size; the tooling fixture continues to clamp the outer circle and the outer surface of the tooth...

Embodiment 3

[0067] The invention discloses a high-toughness tooth circular cutter processing technology, and the processing technology is as follows:

[0068] Step 1: Select materials, select DC53 die steel, and ensure that the content of impurities on the surface and inside of the steel does not exceed 1%, and ensure that the selected high-quality steel raw material specifications are consistent;

[0069] Step 2: Rough turning, use an ordinary horizontal lathe to rough the toothed blade, first select a suitable fixture to clamp the outer circle, the plane at one end of the car is bright, cut the inner hole to the specified size, and leave 20- 30 wire allowance, then remove it, use a small hammer to lightly tap its center, remove the excess material, select a suitable boring tool to grind it; then select a suitable fixture to clamp the inner circle, turn it The thickness of the other end reaches the specified size; the tooling fixture continues to clamp the outer circle and the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com