Carbon nano tube filled copper metal complex nano composite burning rate catalyst

A metal complex, burning rate catalyst technology, applied in non-explosive/non-thermal agent components, offensive equipment, explosives and other directions, can solve the problem of unresearched combustion catalytic performance of composite materials, etc., to improve combustion catalytic performance, specific surface area Large, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

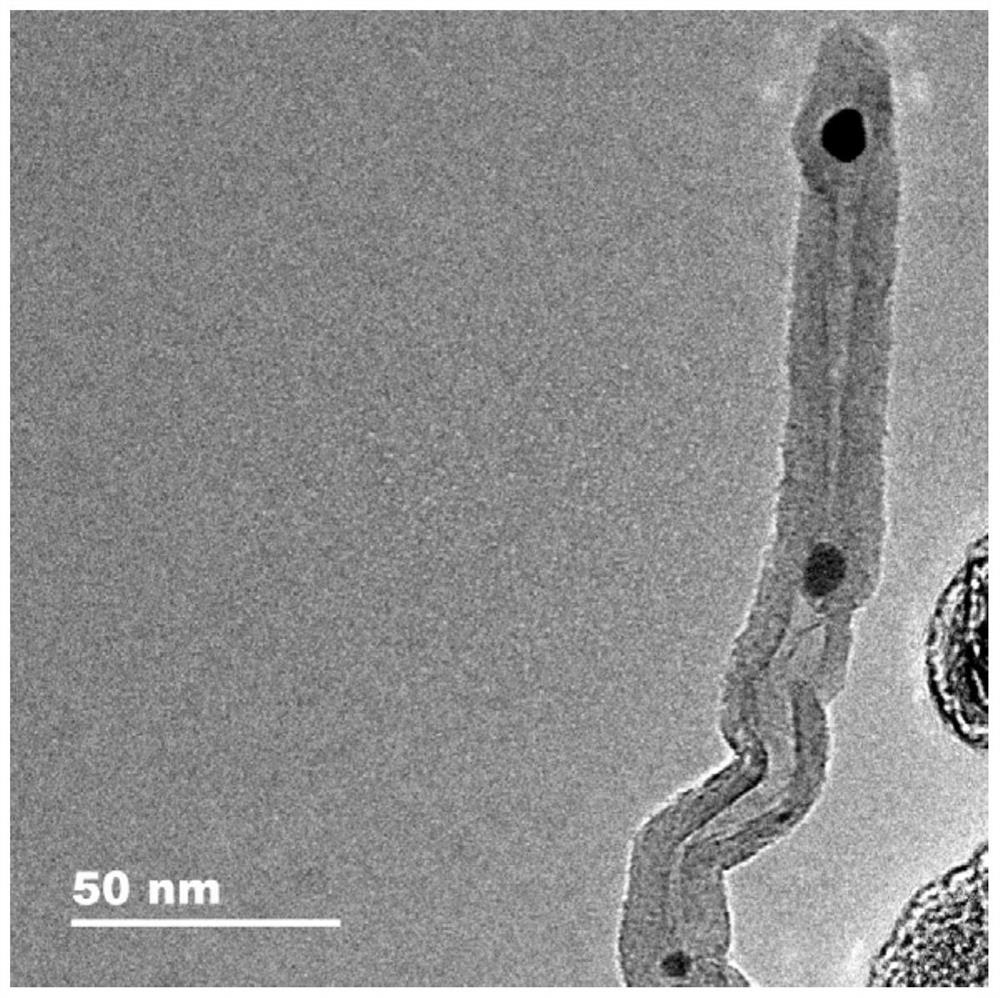

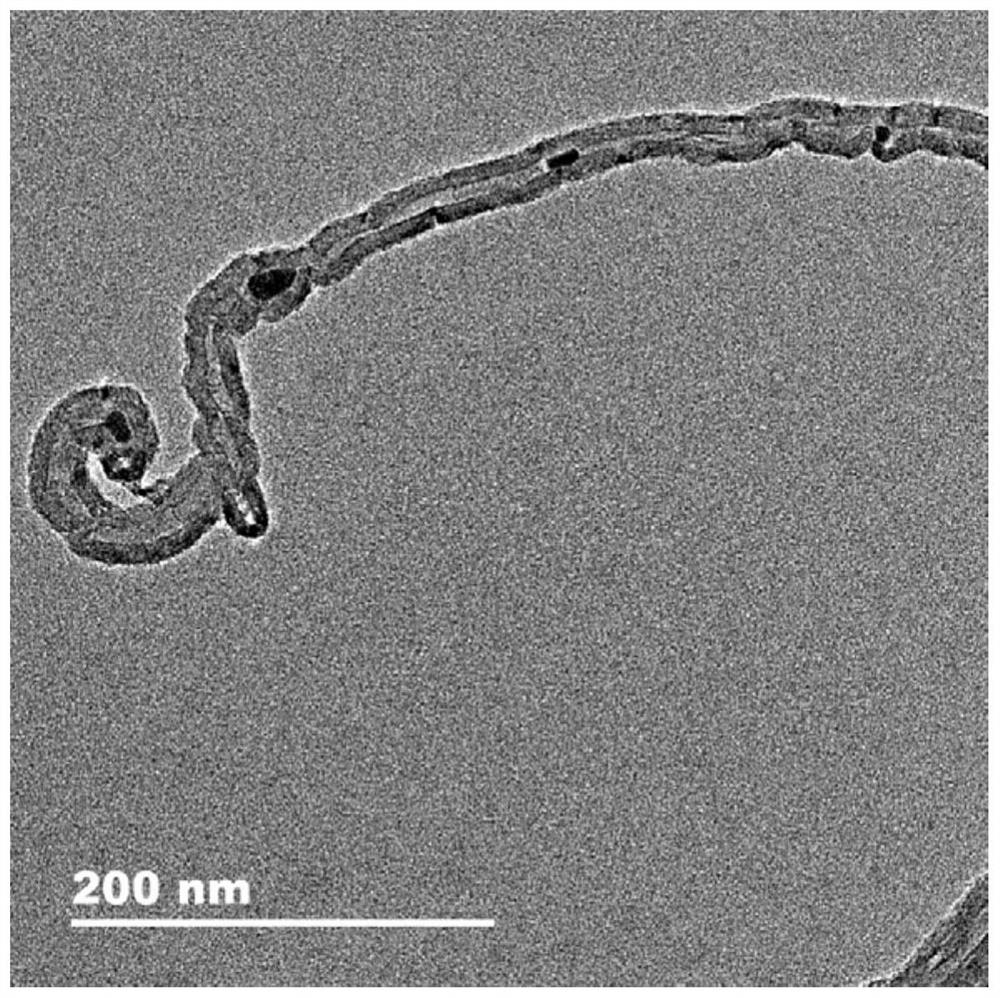

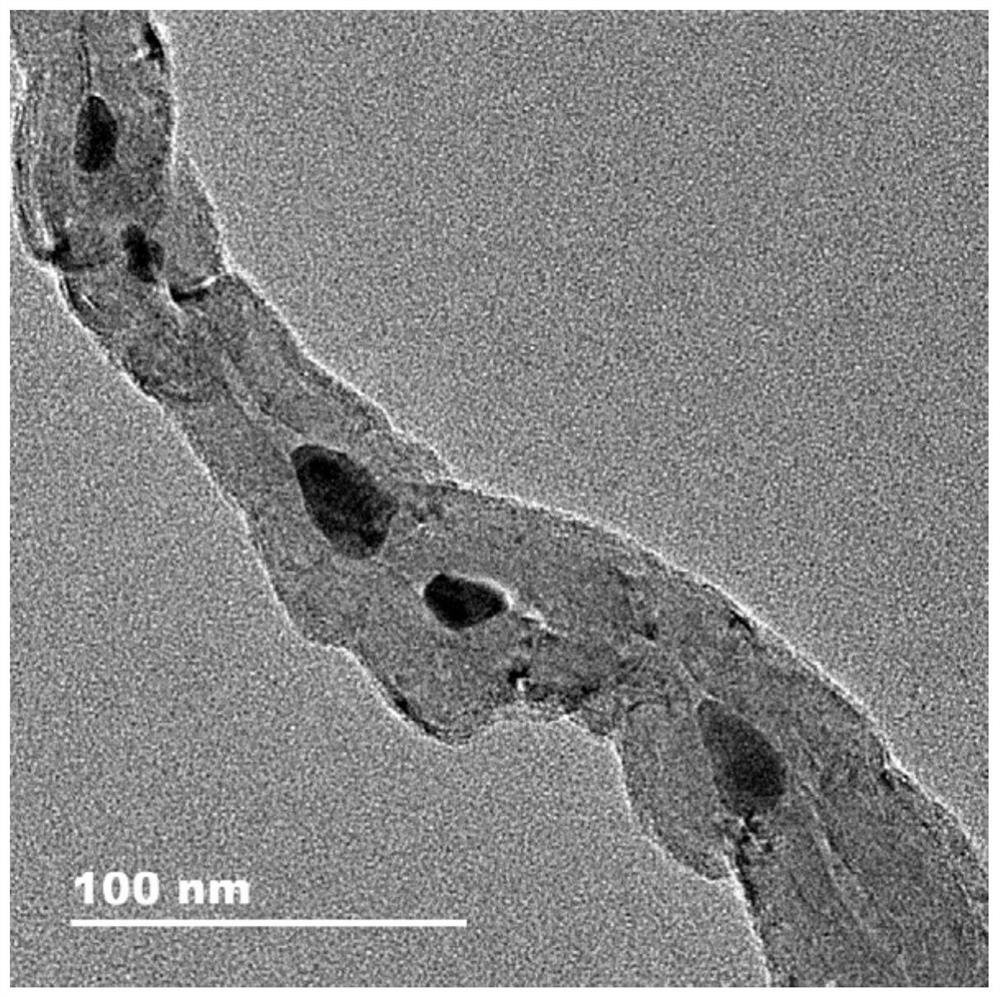

[0026]Add 150 mg of multi-walled carbon nanotubes with a diameter of 4 to 6 nm into 15 mL of a mixed acid solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1, and perform ultrasonic treatment for 4 h at a temperature of 30 ° C and a power of 300 W to obtain a black viscous Thick solution, add deionized water to this solution, stir it evenly with a glass rod, then let it settle at room temperature for 12 hours, you can see that there are obvious layers in the beaker, pour off the upper layer of transparent solution, add deionized water again, and so on After several times a black suspension was obtained. The black suspension was separated by suction filtration, and washed repeatedly with deionized water until the pH of the obtained black solid precipitate was neutral. After the black solid precipitate was transferred to a blast drying oven at 80°C for 12 hours, it was ground evenly. The oxidized carbon nanotubes with open ends were obt...

Embodiment 2

[0028] In this embodiment, the multi-walled carbon nanotubes with a diameter of 5 to 15 nm of equal mass are used to replace the multi-walled carbon nanotubes with a diameter of 4 to 6 nm in Example 1, and the other steps are the same as in Example 1, and the obtained black powder Filling the carbon nanotubes with Cu(NO 3 ) 2 ·3H 2 O nanocomposite burning rate catalyst, Cu(NO 3 ) 2 ·3H 2 The filling ratio of O is 8.2%.

Embodiment 3

[0030] In this embodiment, the multi-walled carbon nanotubes with a diameter of 10 to 20 nm of equal mass are used to replace the multi-walled carbon nanotubes with a diameter of 4 to 6 nm in Example 1. The other steps are the same as in Example 1, and the obtained black powder Filling the carbon nanotubes with Cu(NO 3 ) 2 ·3H 2 O nanocomposite burning rate catalyst, Cu(NO 3 ) 2 ·3H 2 The filling ratio of O is 6.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com