Polyester resin for self-leveling powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of complex preparation process, high cost, incomplete applicable system, etc., and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

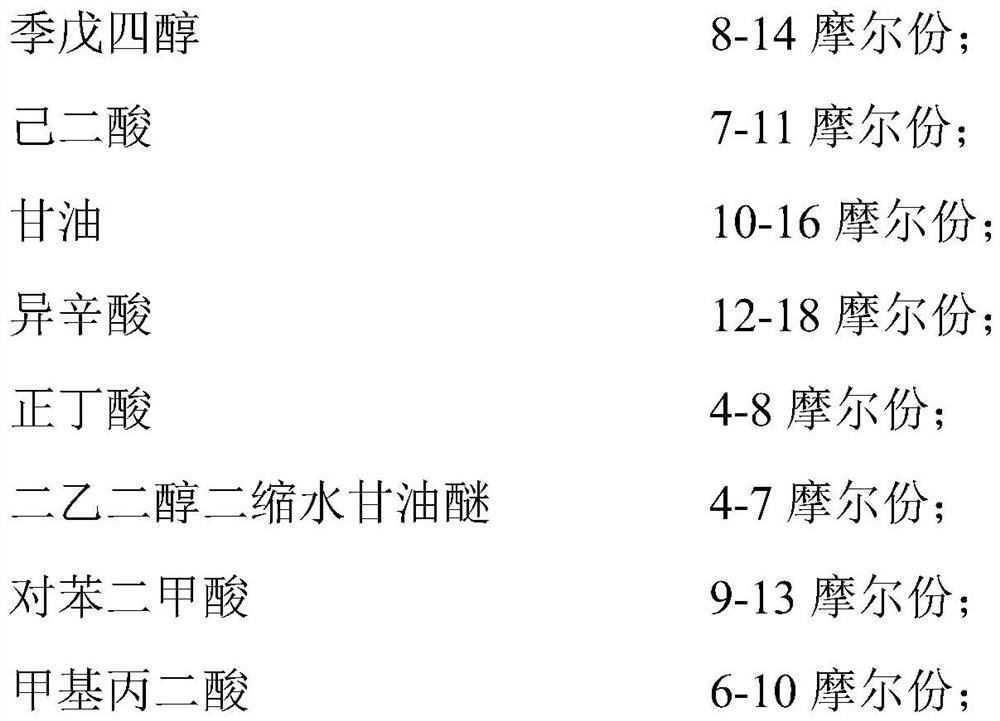

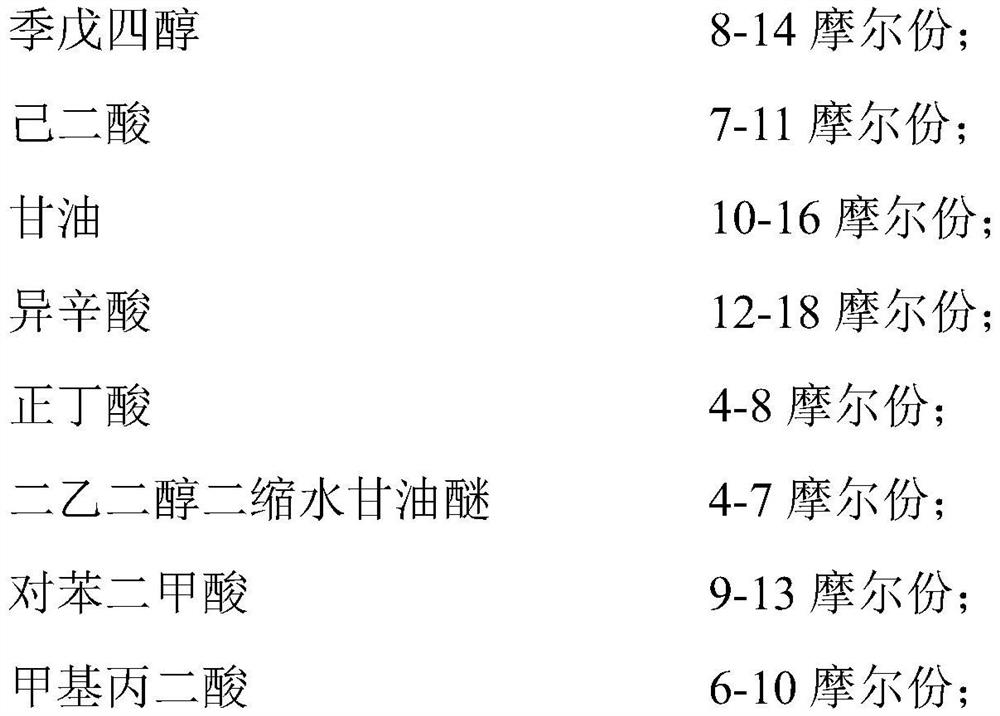

Method used

Image

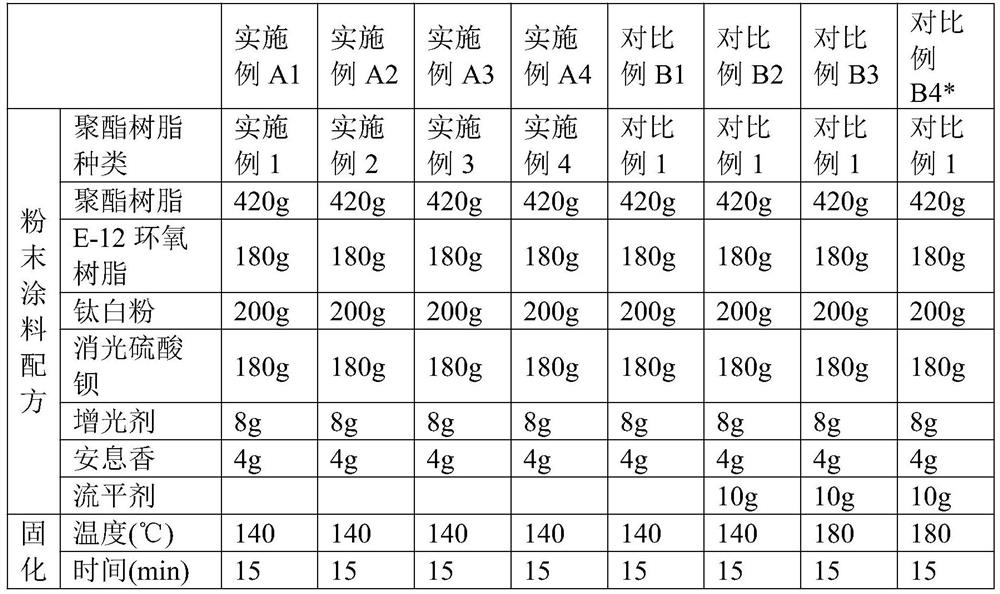

Examples

Embodiment 1

[0036] This embodiment provides a preparation method of polyester resin for self-leveling powder coatings, including:

[0037] (1) Add 9 mole parts of pentaerythritol and 11 mole parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C;

[0038] (2) In the mixed material that step (1) obtains, add the adipic acid of 8 mole fractions, the catalyst monobutyl tin oxide relative to the 0.12% of raw material total molar weight, under nitrogen protection, with 10 DEG C / h The heating rate is raised to 164°C and kept warm to carry out the polymerization reaction;

[0039] (3) When the acid value of the reactant is reduced to below 20mgKOH / g and the hydroxyl value is 380mgKOH / g, stop the reaction, add 17 molar fractions of isooctanoic acid and 5 molar fractions of n-butyric acid, and The heating rate of h is raised to 179° C. and continues to be incubated to carry out the polymerization reaction;

[0040] (4) When the hydroxyl value of the reactant is reduced t...

Embodiment 2

[0047] This embodiment provides a preparation method of polyester resin for self-leveling powder coatings, including:

[0048] (1) Add 13 mole parts of pentaerythritol and 13 mole parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C;

[0049] (2) In the mixed material that step (1) obtains, add the adipic acid of 10 mole fractions, the catalyst monobutyl tin oxide relative to the 0.18% of raw material total molar weight, under nitrogen protection, with 12 DEG C / h The heating rate is raised to 165°C and kept warm to carry out the polymerization reaction;

[0050](3) When the acid value of the reactant is reduced to below 20mgKOH / g and the hydroxyl value is 385mgKOH / g, stop the reaction, add 15 molar fractions of isooctanoic acid and 6 molar fractions of n-butyric acid, and The heating rate of h is raised to 180° C. to continue the insulation to carry out the polymerization reaction;

[0051] (4) When the hydroxyl value of the reactant is reduced to ...

Embodiment 3

[0058] This embodiment provides a preparation method of polyester resin for self-leveling powder coatings, including:

[0059] (1) Add 12 mole parts of pentaerythritol and 14 mole parts of glycerin into the reaction kettle, and stir and mix evenly below 120°C;

[0060] (2) In the mixed material that step (1) obtains, add the adipic acid of 10 mole fractions, the catalyst monobutyl tin oxide relative to the 0.2% of raw material total molar weight, under nitrogen protection, with 11 DEG C / h The heating rate is raised to 163°C and kept warm to carry out the polymerization reaction;

[0061] (3) When the acid value of the reactant is reduced to below 20mgKOH / g and the hydroxyl value is 320mgKOH / g, stop the reaction, add 17 molar fractions of isooctanoic acid and 7 molar fractions of n-butyric acid, and The heating rate of h is raised to 183° C. and continues to be incubated to carry out the polymerization reaction;

[0062] (4) When the hydroxyl value of the reactant is reduced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com