UVLED epitaxial structure, preparation method thereof, and UVLED chip

An epitaxial structure and chip technology, which is applied in electrical components, nanotechnology, circuits, etc., can solve the problems of weakening quantum dot effect, low luminous efficiency of UVLED, and decreased luminous efficiency, and achieve high luminous efficiency and enhanced quantum dot effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

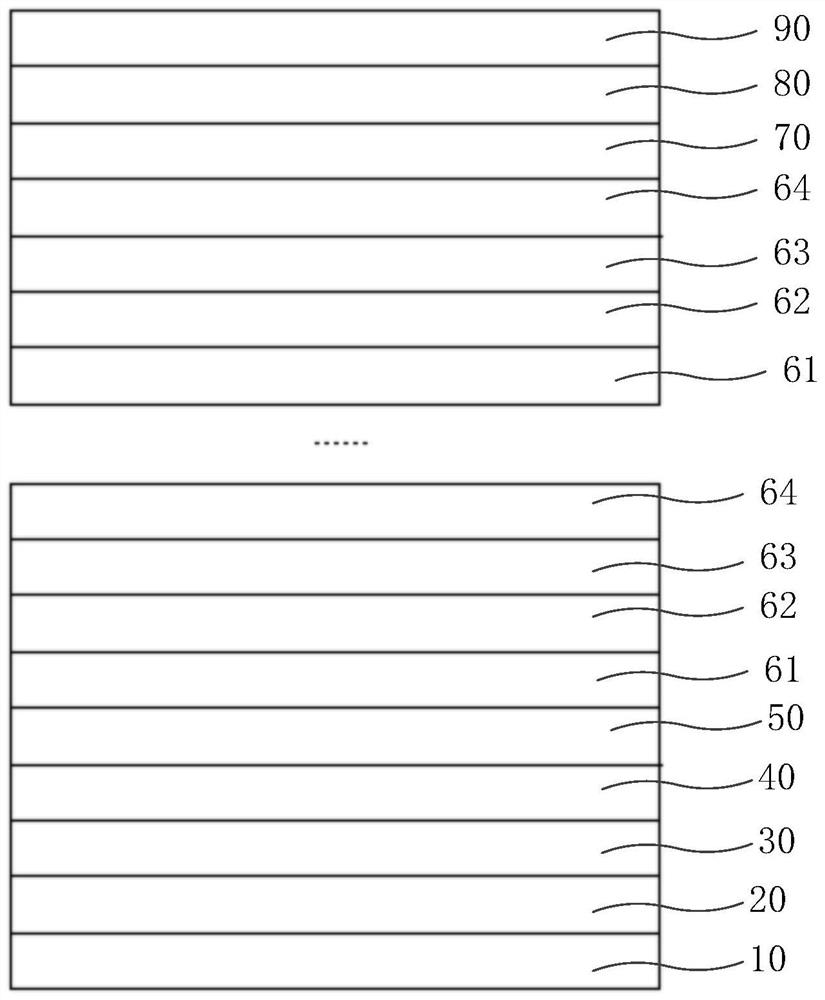

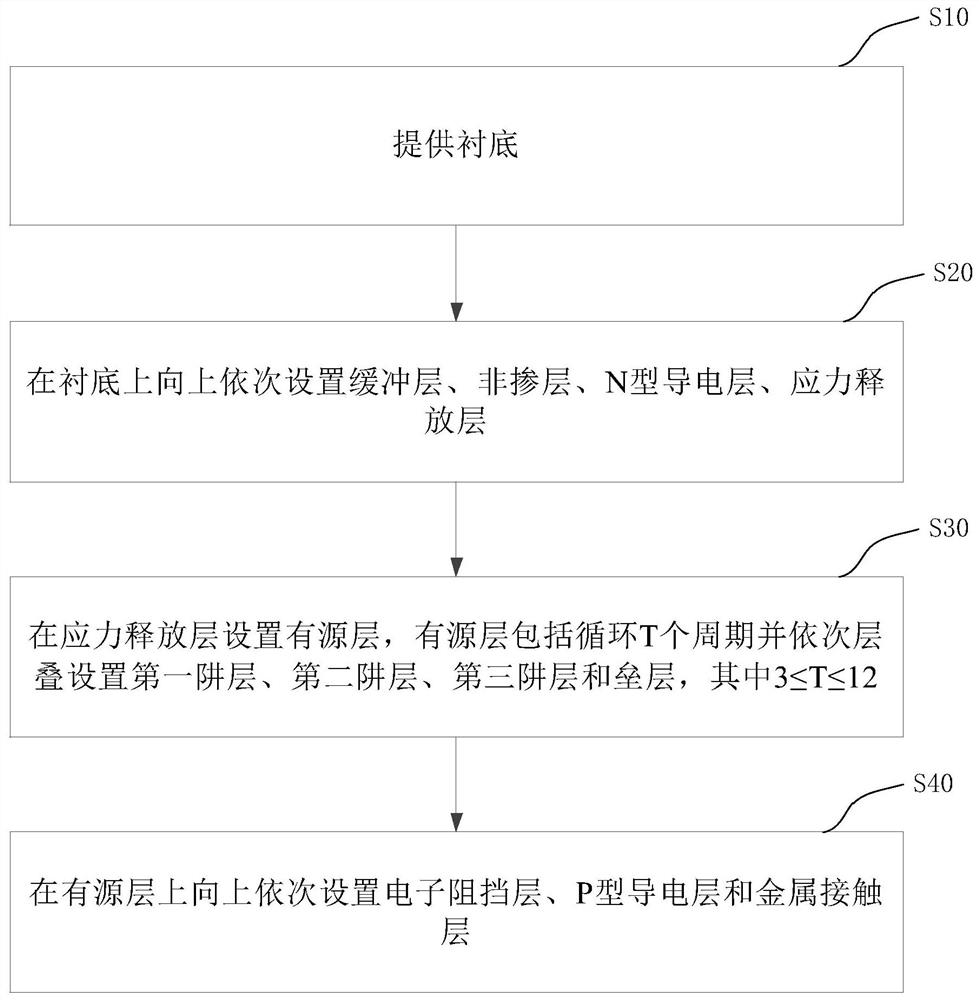

[0076] The present invention also provides a method for preparing a UVLED epitaxial structure, which is used for preparing the above-mentioned UVLED epitaxial structure. refer to image 3 Shown is the flow chart of the preparation method of the UVLED epitaxial structure provided in the first embodiment to the fifth embodiment, and the preparation method includes:

[0077] S10, provide the substrate 10; put the substrate 10 into a metal organic compound vapor phase epitaxy deposition equipment

[0078] S20, a buffer layer 20, a non-doped layer 30, an N-type conductive layer 40, and a stress release layer 50 are sequentially arranged upward on the substrate 10;

[0079] In a possible implementation manner, the growth buffer layer 20 , the undoped layer 30 , the N-type conductive layer 40 , and the stress release layer 50 are sequentially deposited on the substrate 10 .

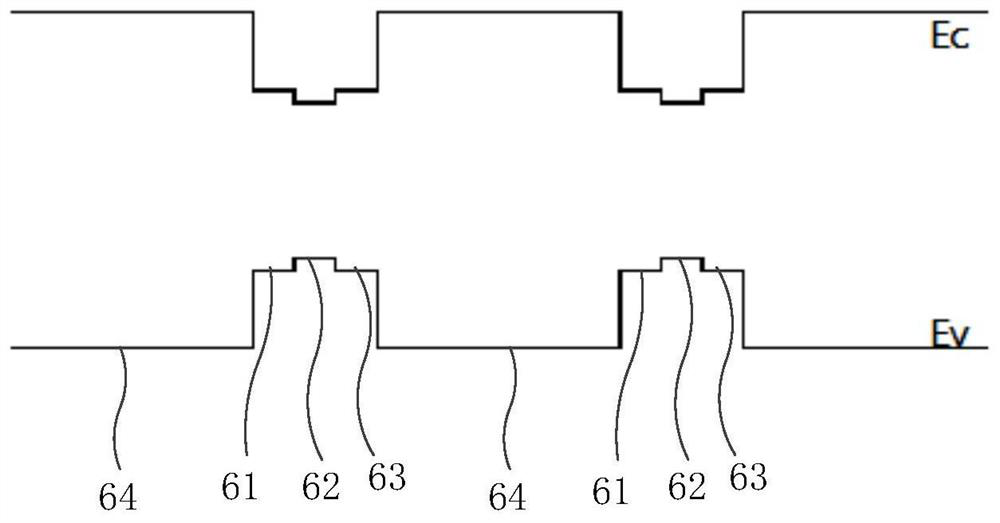

[0080] S30. Repeatedly arrange T active layers 60 on the stress release layer 50. The active layer 60 inclu...

Embodiment 1

[0086] The active layer 60 is grown for 5 cycles in the environment of high-purity hydrogen H2, high-purity N2 or high-purity H2 / N2 mixed gas as the carrier gas, that is, the first well layer 61, the second well layer 62, the third well layer 63 and barrier layer 64 are stacked repeatedly for 5 layers.

[0087] In a possible implementation manner, the flow rate of triethylgallium (TEGa) can be set to 120 sccm, the flow rate of trimethylindium (TMIn) can be set to 200 sccm, and the flow rate of trimethylaluminum (TMAl) Set to 10 sccm, under the conditions of 200 Torr pressure and growth temperature of 840°C, grow for 2min to 5min, control the growth thickness of the first well layer 61 to 1.0nm, and the first well layer 61 is made of Al x1 In y1 Ga (1-x1-y1) N layers, where x1 can be 0.02 and y1 can be 0.025.

[0088] In a possible implementation manner, in S30, the flow of triethylgallium (TEGa) can be set to 120 sccm, the flow of trimethyl indium (TMIn) can be set to 100 s...

Embodiment 2

[0095] The active layer 60 is grown for 5 cycles in the environment of high-purity hydrogen H2, high-purity N2 or high-purity H2 / N2 mixed gas as the carrier gas, that is, the first well layer 61, the second well layer 62, the third well layer 63 and barrier layer 64 are stacked repeatedly for 5 layers.

[0096] The flow rate of trimethylindium (TMIn) in the first well layer 61 is set to 100 sccm, the flow rate of trimethylaluminum (TMAl) is set to 15 sccm, under the conditions of a pressure of 200 Torr and a growth temperature of 840° C., grow for 2 minutes to 5 minutes, control the growth thickness of the first well layer 61 to be 1.0 nm, and the first well layer 61 is made of Al x1 In y1 Ga (1-x1-y1) N, where x1 can be 0.025 and y1 can be 0.015;

[0097] The flow rate of trimethylindium (TMIn) in the third well layer 63 is set to 100 sccm, the flow rate of trimethylaluminum (TMAl) is set to 15 sccm, under the conditions of a pressure of 200 Torr and a growth temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com