A preparation method of c/n co-doped porous cuprous oxide nanospheres based on sericin

A technology of sericin and cuprous oxide, which is applied in the fields of nanotechnology, copper oxide/copper hydroxide, and nanotechnology for materials and surface science, can solve the problem of low catalytic efficiency of cuprous oxide nanomaterials, and achieve Improve photocatalytic efficiency, process stability, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

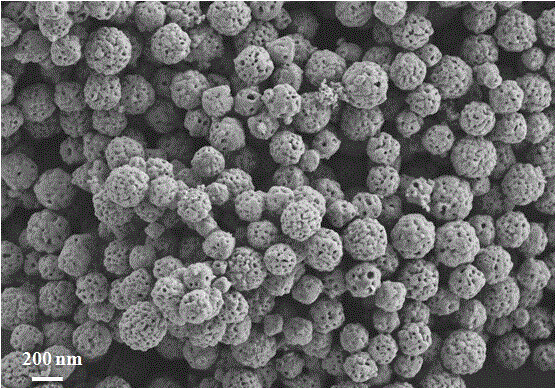

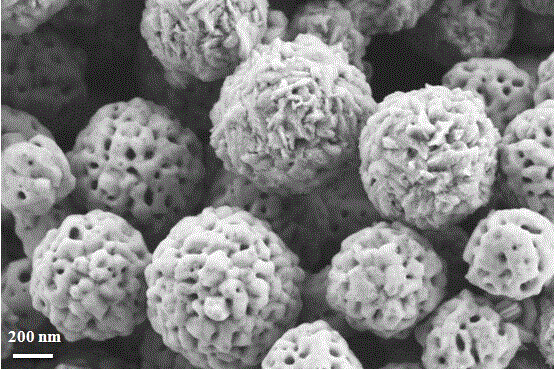

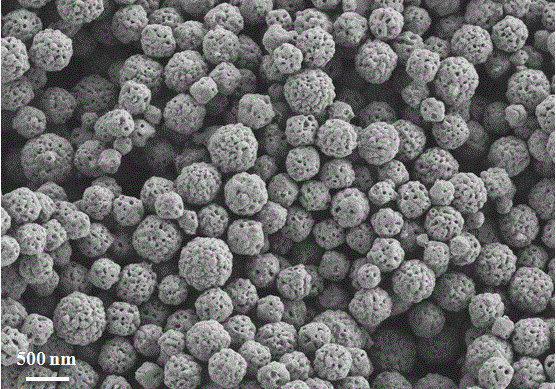

[0024] (1) Preparation of cuprous oxide-sericin composite nanospheres: dissolving sericin with a molecular weight of 1 000 in water to prepare a sericin solution with a concentration of 5 wt %; Add the solution into 100mL of copper sulfate solution with a concentration of 0.1mol / L, and after mixing evenly under magnetic stirring, adjust the pH value of the above-mentioned sericin-copper sulfate mixed solution to 8 with 1M NaOH solution; The ratio is 3:2, adding glucose reducing agent to react for 0.5h, centrifuging at 12000rpm for 10min to collect the precipitate, washing by centrifugation and then drying to obtain cuprous oxide-sericin composite nanospheres;

[0025] (2) Preparation of C / N co-doped porous cuprous oxide nanospheres: the cuprous oxide-sericin composite nanospheres obtained in step (1) were placed in a tube furnace, and under the protection of argon, the The temperature was raised to 400°C at a rate of °C / min, kept at a constant temperature for 2 hours, and cool...

Embodiment 2

[0027] (1) Preparation of cuprous oxide-sericin composite nanospheres: dissolving sericin with a molecular weight of 8000 in water to prepare a sericin solution with a concentration of 2wt%; Add the solution into 100mL of copper nitrate solution with a concentration of 0.3mol / L, and after mixing evenly under magnetic stirring, adjust the pH value of the above-mentioned sericin-copper nitrate mixed solution to 10 with 1M NaOH solution; The ratio is 2:2, adding glucose reducing agent to react for 1 hour, centrifuging at 12 000 rpm for 10 minutes to collect the precipitate, washing by centrifugation and drying to obtain cuprous oxide-sericin composite nanospheres;

[0028] (2) Preparation of C / N co-doped porous cuprous oxide nanospheres: the cuprous oxide-sericin composite nanospheres obtained in step (1) were placed in a tube furnace, and under the protection of argon, the The temperature was raised to 400°C at a rate of °C / min, kept at a constant temperature for 2 hours, and co...

Embodiment 3

[0030] (1) Preparation of cuprous oxide-sericin composite nanospheres: dissolve sericin with a molecular weight of 20,000 in water to prepare a sericin solution with a concentration of 0.5 wt %; Add the protein solution into 100 mL of copper acetate solution with a concentration of 0.1 mol / L, mix evenly under magnetic stirring, and adjust the pH value of the above-mentioned sericin-copper acetate mixed solution to 11 with 1M NaOH solution; The molar ratio is 1:2, adding glucose reducing agent to react for 3 hours, centrifuging at 12 000 rpm for 10 minutes to collect the precipitate, washing by centrifugation and drying to obtain cuprous oxide-sericin composite nanospheres;

[0031] (2) Preparation of C / N co-doped porous cuprous oxide nanospheres: the cuprous oxide-sericin composite nanospheres obtained in step (1) were placed in a tube furnace, and under the protection of argon, the The temperature was raised to 500°C at a rate of °C / min, kept at a constant temperature for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com