A kind of titanium dioxide/boron nitride composite material and its preparation method and application

A technology of titanium dioxide and composite materials, applied in the direction of titanium oxide/hydroxide, titanium dioxide, catalyst activation/preparation, etc., can solve the problems that hinder the wide and in-depth development of technology, limit the utilization of solar energy, affect the utilization of visible light, etc. problems, to achieve the effect of improving unique properties, reducing the probability of compounding, and enhancing the effect of photodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of titanium dioxide / boron nitride composite material in the first aspect, described method comprises the steps:

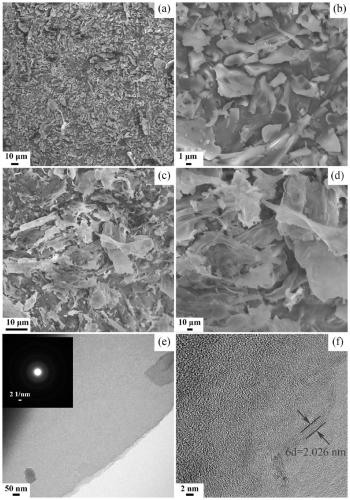

[0038] (1) Mix boric acid, carbon source (such as glucose or sucrose), nitric acid and urea with water (such as distilled water or deionized water) to obtain a mixed solution, and then heat the mixed solution to 300-500° C. (for example, 300 ℃, 350°C, 400°C, 450°C or 500°C) for 15 to 30 minutes (for example, 15, 20, 25 or 30 minutes) to obtain a precursor, and then the precursor is passed through ammonia gas at a temperature of 700 to 1000°C (such as 700°C, 800°C, 900°C or 1000°C) for 2 to 5 hours (such as 2, 3, 4 or 5 hours) to prepare boron nitride, which is a sheet-shaped hexagonal nitride boron (flaky hexagonal boron nitride); and

[0039] (2) Mix the titanium source and the boron nitride prepared in step (1) uniformly with an alcohol solvent to obtain a mixture, and then place the mixture in a...

Embodiment 1

[0057] Example 1: Preparation experiment of titanium dioxide / boron nitride composite material.

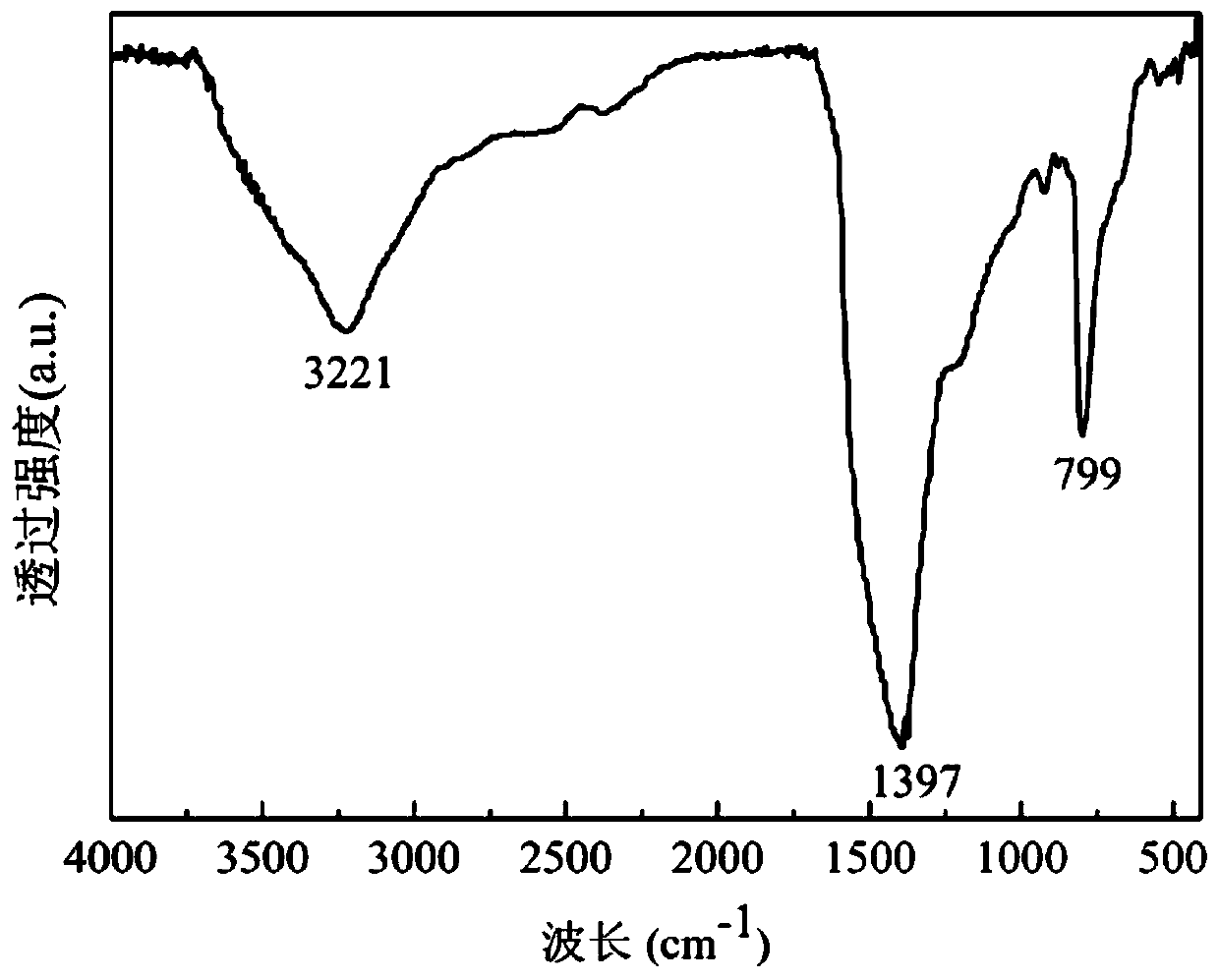

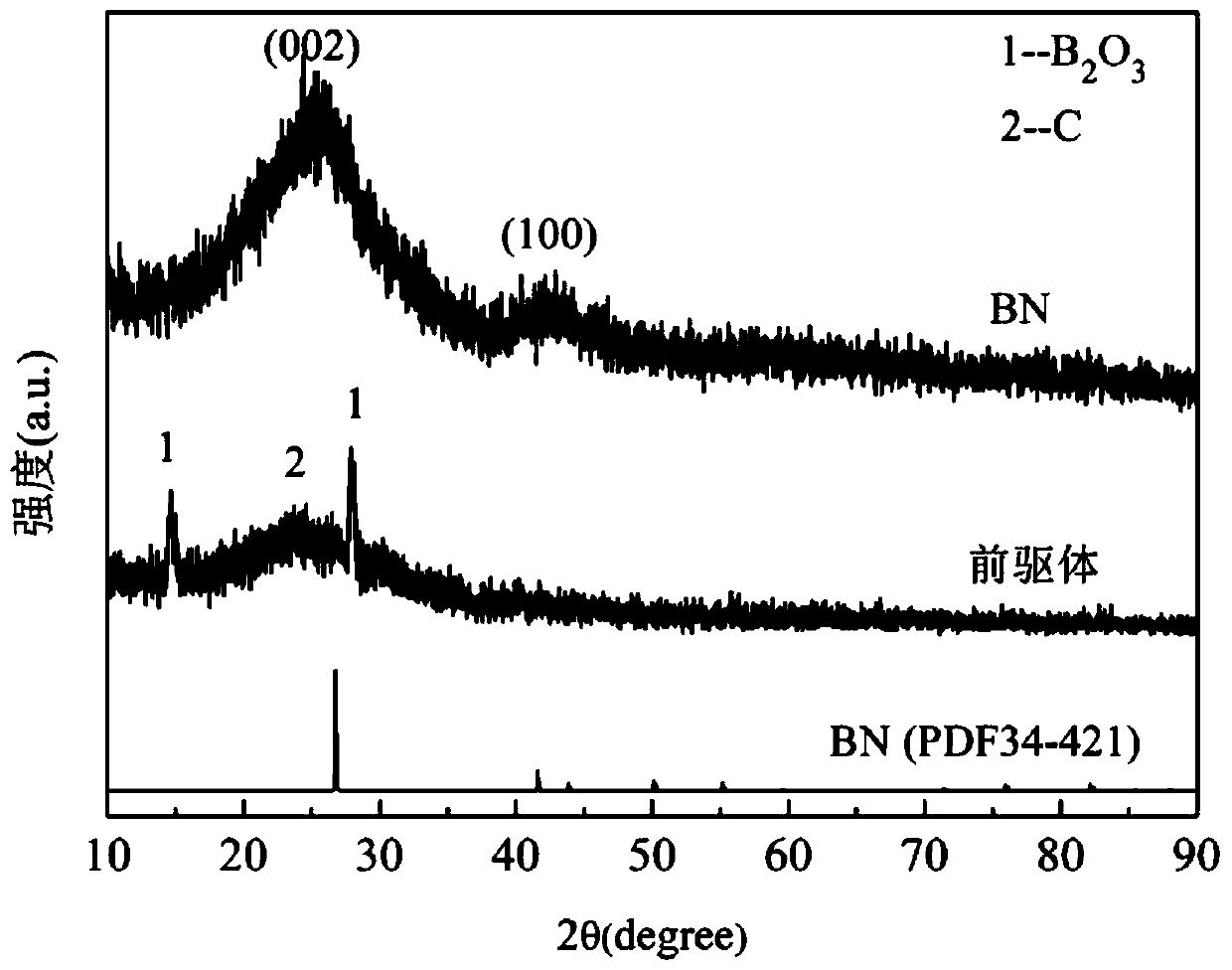

[0058] ①Preparation of boron nitride: the molar ratio of the raw materials boric acid, grape monohydrate, nitric acid and urea is 2:3:5:6, put the above-mentioned raw materials in a clean beaker, add 100mL of water, and keep stirring with glass Until all the solids are completely dissolved, the clarified mixed solution is finally obtained, and then the mixed solution is transferred to a porcelain boat, and the porcelain boat is put into a muffle furnace to start heating and heating (the heating rate is 15° C. / min). Carry out, the solution in the porcelain boat begins to bubble in the range of 90-100°C, and the solution starts to bubble when heated to about 350°C, and yellow foam appears. At this time, turn off the muffle furnace and let the reaction proceed spontaneously. The bottom of the boat expands to the mouth of the porcelain boat, releasing a lot of heat and yellow and black...

Embodiment 2

[0064] Example 2: Experiment of removal of rhodamine B by titanium dioxide / boron nitride composite material.

[0065] The titanium dioxide / boron nitride composite material used in this example is the titanium dioxide / boron nitride composite material prepared in Example 1.

[0066] Prepare 20 mL of Rhodamine B solution with an initial concentration of 10 mg / L (three parallel preparations), and record the initial concentration of Rhodamine B solution as C 0 .

[0067] Subsequent treatment process of three rhodamine B solutions: one part has not added titanium dioxide / boron nitride composite material (the mass ratio containing titanium dioxide and boron nitride is 8.6:1) (blank sample, denoted as blank), this part of solution Stir with magnetic force and place in dark environment for 30min (dark means dark environment), then irradiate with xenon lamp for 90min while magnetic stirring (light intensity is 100mW / cm 2 , using light to indicate xenon lamp irradiation); the other two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com