Preparation method, thin film and solar cell of germanium-doped copper-zinc-tin-sulfur-selenium thin film

A technology for preparing copper-zinc-tin-sulfur-selenium and thin films, which is applied in the field of solar photovoltaics, can solve the problems of difficult removal of organic solvents, small CZTS crystal grains, high price, etc., so as to improve the photoelectric conversion efficiency, reduce the sintering temperature, and promote the growth of crystal grains. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

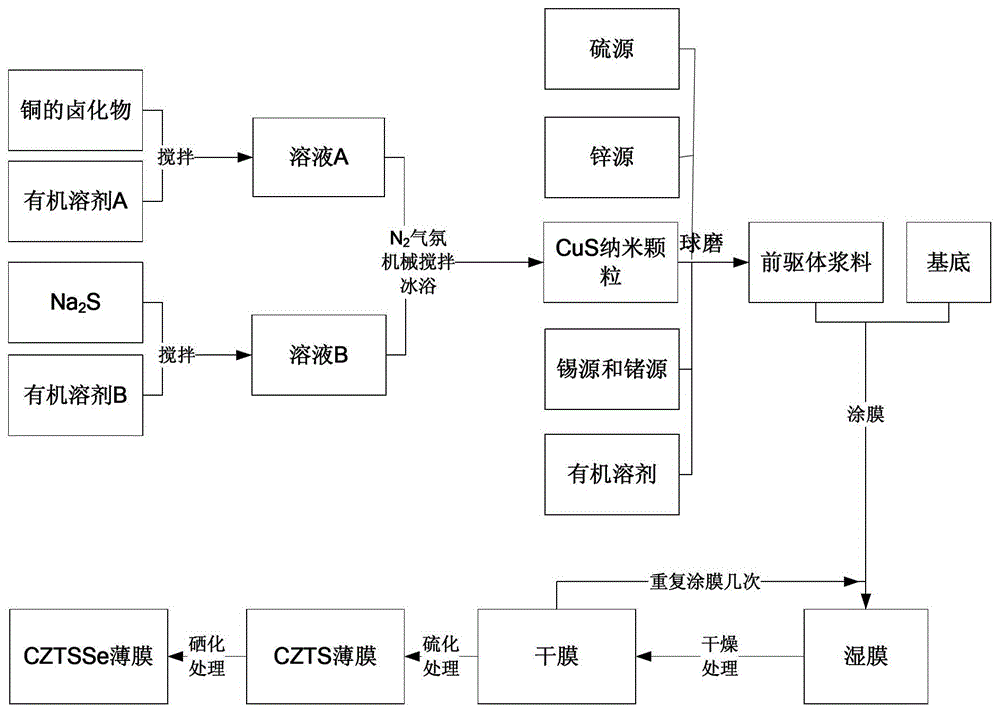

[0032] Such as Figure 1 to Figure 3 As shown, a method for preparing a germanium-doped copper-zinc-tin-sulfur-selenium thin film of the present application, an embodiment thereof, comprises the following steps:

[0033] Step 1, preparing CuS nanoparticles.

[0034] The steps for preparing CuS nanoparticles specifically include:

[0035] Copper halide and Na 2 S is respectively dissolved in an organic solvent;

[0036] The solution of dissolved copper halide and dissolved Na 2 The solution of S is mixed;

[0037] The mixed solution was stirred under ice bath conditions to obtain a colloidal solution;

[0038] The colloidal solution is centrifuged with a centrifuge to obtain CuS nanoparticles.

[0039] In a nitrogen-filled glove box, the copper halide and Na 2 S was dissolved in the organic solvent respectively, and after stirring for 1-20 min, it was taken out from the glove box, and the two solutions were mixed in the fume hood. Copper halides including CuCl 2 、CuBr ...

Embodiment 1

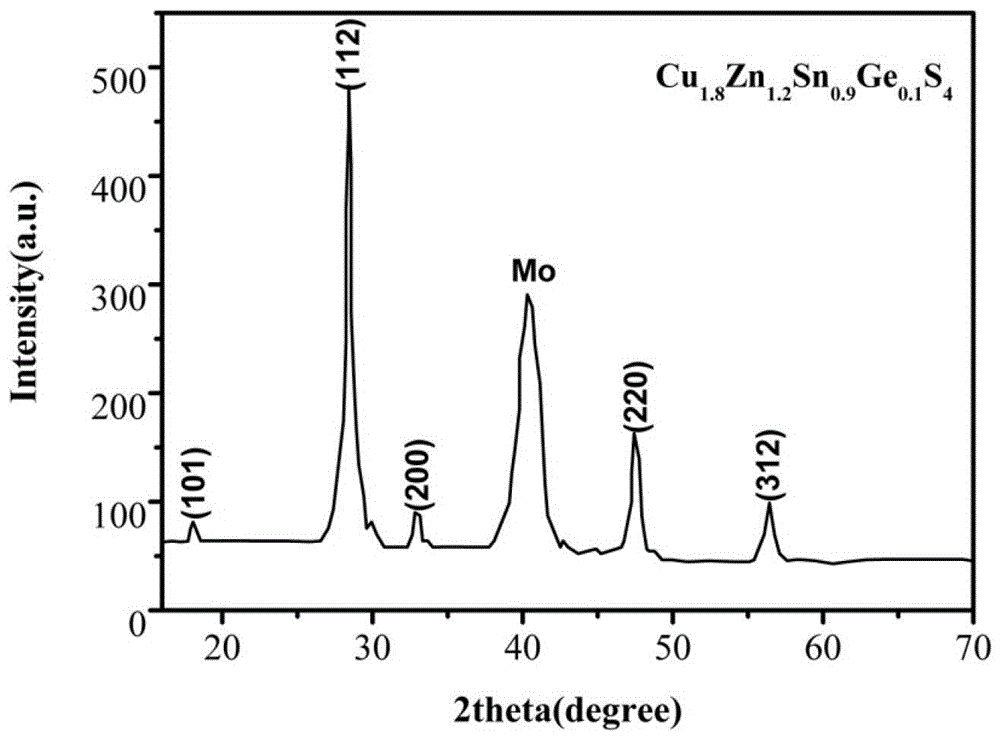

[0053] Such as figure 1 As shown, the CuI 2 and Na 2 S was dissolved in pyridine and methanol solvents respectively, stirred in the glove box for a few minutes, and mixed in a fume hood after being taken out from the glove box to obtain a black sol. The black sol was centrifuged with a high-speed centrifuge to collect CuS nanoparticles at a speed of 10000 rpm for 10 min. Mix the prepared CuS nanoparticles with sulfur powder, zinc powder, tin powder, and germanium powder, wherein the molar ratio of Cu:Zn:Sn:Ge:S is 1.8:1.2:0.9:0.1:4, adding an appropriate amount of ethanol as The dispersant makes the concentration of the solid particles of the precursor slurry 20g / L, and the ball mill is carried out by using a high-speed ball mill, the speed of the ball mill is 400r / min, and the ball milling time is 5h. A precursor film was prepared on the Mo-coated soda-lime glass by scraping the prepared precursor slurry, and the precursor film was obtained after baking at 80° C. for 60 mi...

Embodiment 2

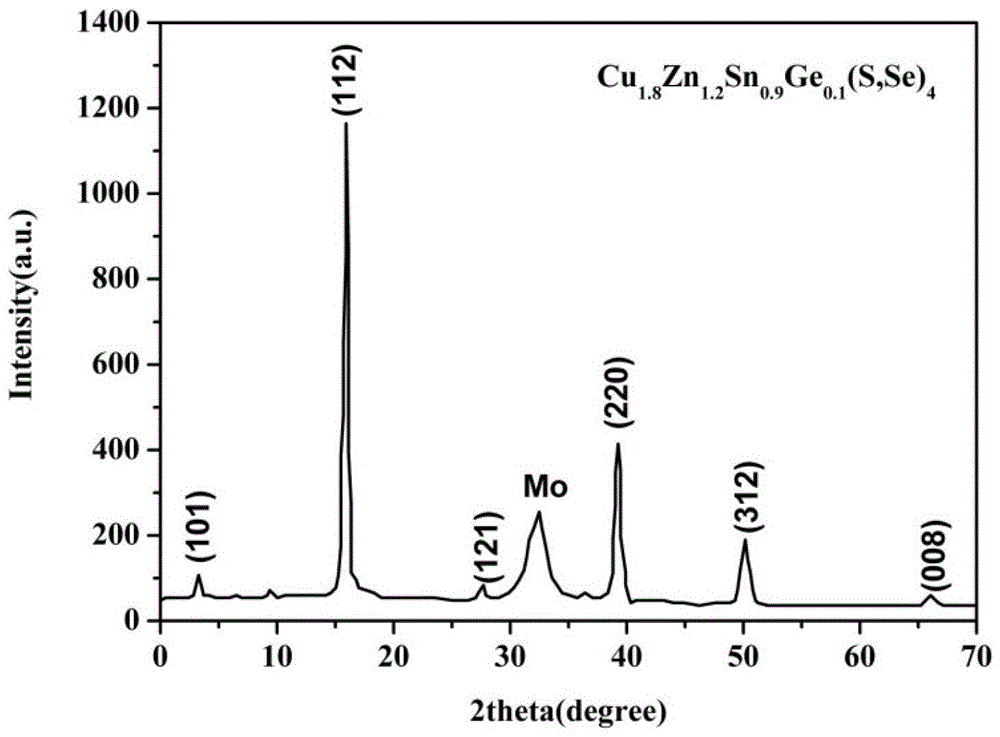

[0055] CuCl 2 and Na 2 S was dissolved in ethanol and formamide solvents respectively, stirred in the glove box for a few minutes, and mixed in a fume hood after being taken out from the glove box to obtain a black sol. The black sol was centrifuged by a high-speed centrifuge to collect CuS nanoparticles at a speed of 12000 rpm for 10 min. Mix the prepared CuS nanoparticles with sulfur powder, zinc sulfide, tin selenide, and germanium powder, wherein the molar ratio of Cu:Zn:Sn:Ge:S is 1.5:1.5:0.3:0.7:4, adding an appropriate amount of toluene As a dispersant, the concentration of the solid particles of the precursor slurry was 1 g / L, and a high-speed ball mill was used for ball milling. The rotational speed of the ball mill was 1400 r / min, and the ball milling time was 30 h. The prepared precursor slurry was used to prepare a precursor film on a stainless steel substrate by dipping and pulling method, and after drying at 250° C. for 10 min, the precursor film was obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com