Lithium ion battery with high energy density

A lithium-ion battery, high energy density technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of poor conductivity, slow charging rate, low compaction density, etc. Cycle performance, improved rate performance, high specific energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

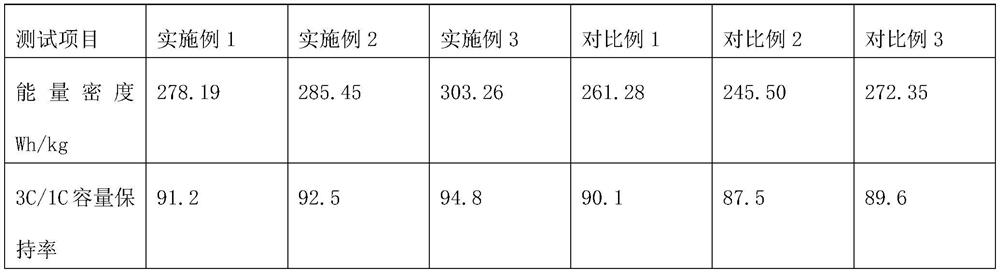

Examples

preparation example Construction

[0024] The preparation method of the positive electrode active material used in the examples is as follows: Stir the liquid polyacrylonitrile oligomer-ethanol solution with a concentration of 50% at 90-120° C. for 9-12 hours, add lithium nickel manganate material LiNi 0.5 mn 1.5 o 4 / LiNi x co y mn 1-x-y o 2 Mix evenly, evaporate completely at 75-85°C, fully cross-link at 200-220°C, calcinate at 850-1000°C for 10-20 hours in an air atmosphere, and carbonize to obtain the positive electrode active material.

[0025] The positive electrode conductive agent is graphene.

Embodiment 1

[0027] A lithium-ion battery with high energy density, comprising a positive electrode sheet, a negative electrode sheet, a diaphragm and an electrolyte, the positive electrode sheet includes a positive electrode current collector and a positive electrode composite material, and the positive electrode composite material includes a positive electrode active material, a positive electrode conductor and an adhesive binder; the positive electrode conductive agent includes lithium iron phosphate coated with carbon nanotubes; the positive electrode active material has a core-shell structure, and the shell layer is LiNi coated with graphene 0.5 mn 1.5 o 4 , the core layer is LiNi 0,9 co 0.05 mn 0.05 o 2 , the shell material is 15% of the mass of the core material, LiNi 0.5 mn 1.5 o 4 The mass accounts for 90% of the total mass of the shell material; the binder is sodium carboxymethyl cellulose, polyolefin and styrene-butadiene rubber in a mass ratio of 0.6:1.5:3.

[0028] The...

Embodiment 2

[0030] A lithium-ion battery with high energy density, comprising a positive electrode sheet, a negative electrode sheet, a diaphragm and an electrolyte, the positive electrode sheet includes a positive electrode current collector and a positive electrode composite material, and the positive electrode composite material includes a positive electrode active material, a positive electrode conductor and an adhesive binder; the positive electrode conductive agent includes lithium iron phosphate coated with carbon nanotubes; the positive electrode active material has a core-shell structure, and the shell layer is LiNi coated with graphene 0.5 mn 1.5 o 4 , the core layer is LiNi 0,9 co 0.05 mn 0.05 o 2 , the shell material is 15% of the mass of the core material, LiNi0.5 mn 1.5 o 4 The mass accounts for 90% of the total mass of the shell material; the binder is sodium carboxymethyl cellulose, polyolefin and styrene-butadiene rubber with a mass ratio of 0.6:1.5:3; the positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com