Slurry covering flame-retardant slurry for fire extinguishing of gangue dump and application thereof

A gangue dump and slurry technology, which is applied in the field of flame retardant slurry coating, can solve the problems of large environmental impact, large engineering volume, large pores of gangue dump, etc., and achieve the effect of good cooling effect, low preparation cost and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

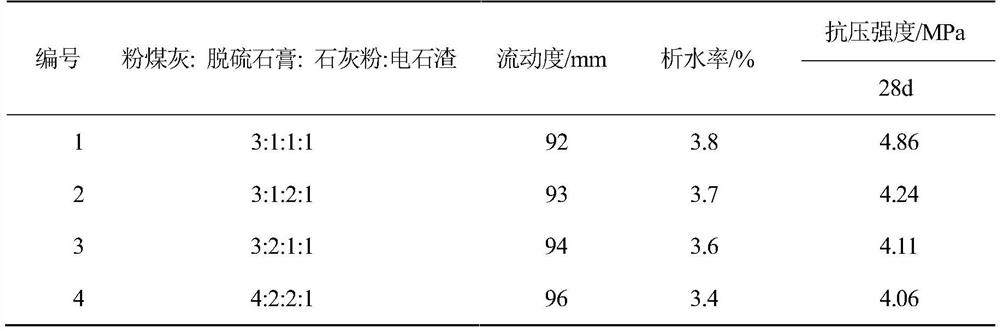

[0054] This embodiment is used in the application of a plasma flame retardant slurry for a mesiushan fire extinguishing, including the following steps:

[0055] (1) According to the mass, 60 parts of the fly ash, 20 desulfurization gypsum, 25 pieces of lime powder, 20 melamine residue, melamine formaldehyde resin modified polyphosphate 10 parts and 160 parts of water, stir evenly Squirting barrier. The measuring fluid degree was measured using cement rubber sand.

[0056] (2) Pour the slurry into a mortar triple test die of 70.7 × 70.7 × 70.7, together with the test mold on the temperature (20 ± 2) ° C, relative humidity ≥ 50%, 48h, after 48 hours, the test block is placed In the temperature (20 ± 1) ° C, the relative humidity is not less than 90% of the maintenance case, the pressure resistance intensity of the test block is 4.2 MPa, and the softening coefficient of the softening coefficient of 0.91 is 0.91.

Embodiment 2

[0058] This embodiment is used in the application of a plasma flame retardant slurry for a mesiushan fire extinguishing, including the following steps:

[0059] (1) According to mass, 70 copied coal ash, 25 desulfurized gypsum, 30 pieces of lime powder, 25 parts of melamine residue, 20 parts of polycanoamide modified by melamine formaldehyde resin, 3 parts of polyacrylamide, carboxamide Methylcellulose 5 parts, 2 parts of expandable graphite, 5 parts of polyethylene glycol 400 and 200 parts of water, and stir evenly gave a plaquaculus. The measuring fluid degree was determined using cement rubber sand.

[0060] (2) Pour the slurry into a mortar triple test die of 70.7 × 70.7 × 70.7, together with the test mold on the temperature (20 ± 2) ° C, relative humidity ≥ 50%, 48h, after 48 hours, the test block is placed In the temperature (20 ± 1) ° C, the relative humidity is not less than 90% of the maintenance case, the compressive strength of the test block is 4.6 MPa, and the softeni...

Embodiment 3

[0062] This embodiment is used in the application of a plasma flame retardant slurry for a mesiushan fire extinguishing, including the following steps:

[0063](1) According to the mass, 80 copied coal ash, 40 desulfurized gypsum, 45 pieces of lime powder, 30 pieces of melamine, melamine formaldehyde resin modified polyphosphate 15 parts, 4 parts of polyacrylamide, carboxarboxy The methylcellulose, 4 parts of expandable graphite, 10 parts of polyethylene glycol 400 and 270 moisture, stirred and uniformly obtained. The measuring fluid degree was determined using cement rubber sand.

[0064] (2) Pour the slurry into a mortar triple test die of 70.7 × 70.7 × 70.7, together with the test mold on the temperature (20 ± 2) ° C, relative humidity ≥ 50%, 48h, after 48 hours, the test block is placed In the temperature (20 ± 1) ° C, the relative humidity is not less than 90% of the maintenance case, the compressive strength of the test block is 4.8 MPa, and the softening coefficient of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com