Nitrogen-doped porous carbon material adsorbent for treating dye wastewater as well as preparation method and application thereof

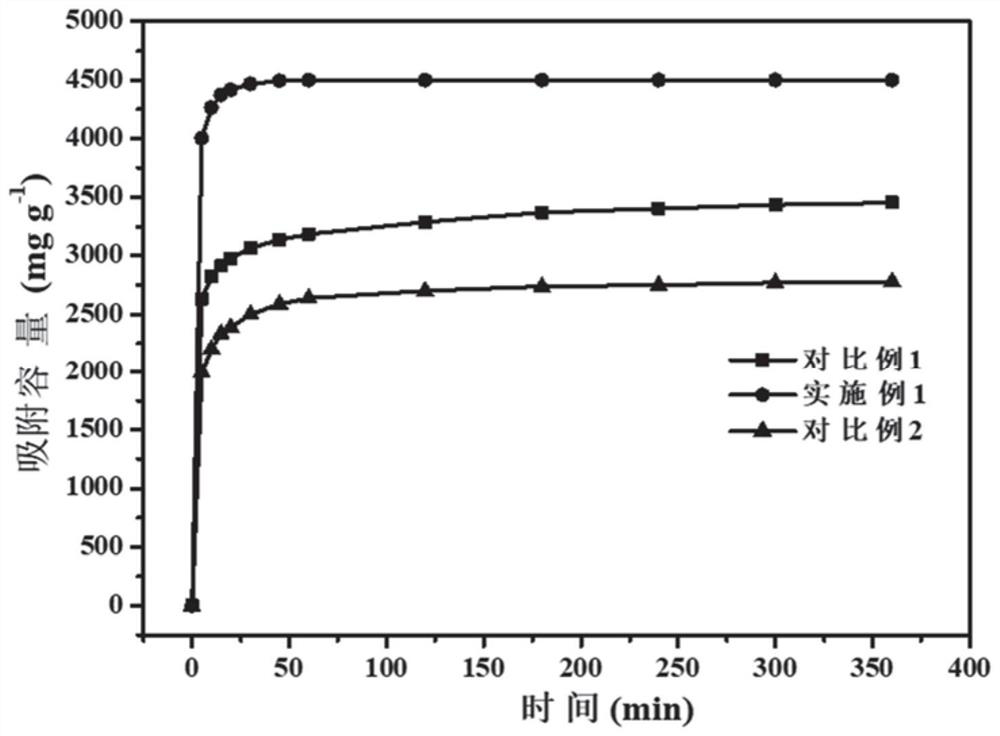

A technology for nitrogen-doped porous carbon and dye wastewater, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve simple treatment process, simple preparation process, and large adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] One aspect of the embodiments of the present invention provides a method for preparing a nitrogen-doped porous carbon material adsorbent for treating dye wastewater, comprising:

[0027] uniformly mixing and grinding walnut shells and a nitrogen source to obtain a first mixture;

[0028] Carrying out carbonization treatment on the first mixture in a protective atmosphere, the temperature of the carbonization treatment is 50°C-550°C, and the time is 1-3h;

[0029] uniformly mixing and grinding the obtained carbonized product with the potassium salt to obtain a second mixture;

[0030] In a protective atmosphere, the second mixture is subjected to activation treatment, the temperature of the activation treatment is 50° C. to 800° C., and the time is 1 to 3 hours to obtain a nitrogen-doped porous carbon material adsorbent for treating dye wastewater.

[0031] Further, the particle size of the walnut shell may be between 100 and 150 mesh.

[0032] Further, the nitrogen so...

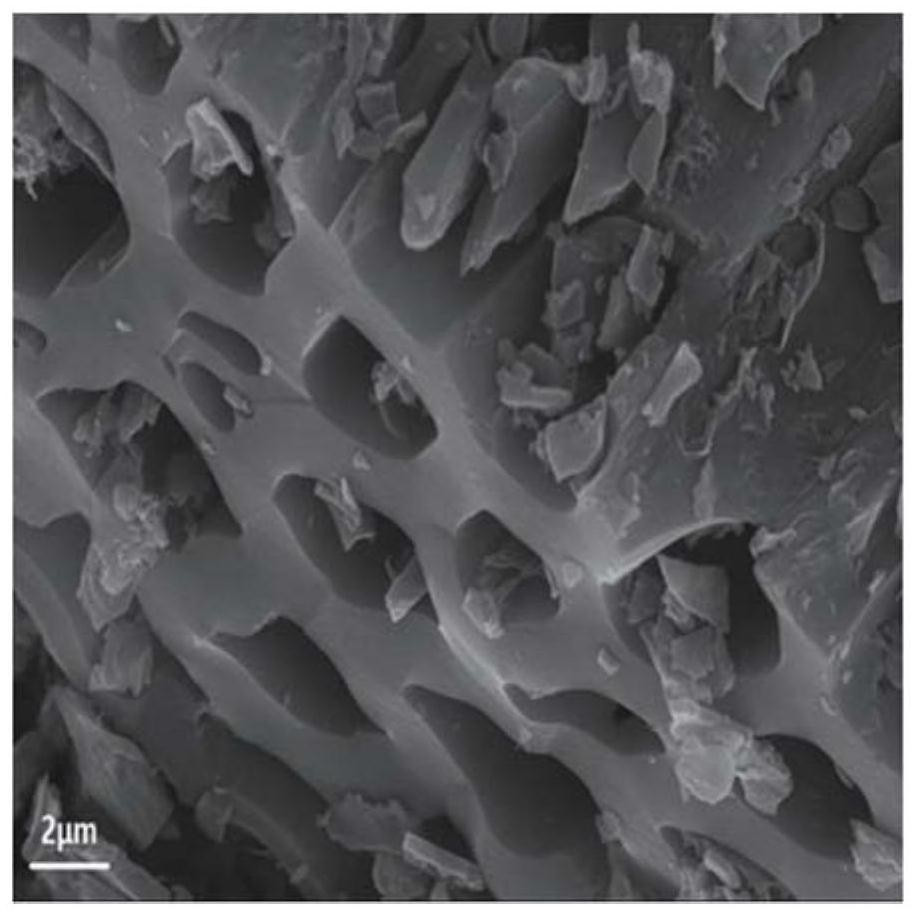

Embodiment 1

[0062] Example 1 A method for preparing a nitrogen-doped porous carbon material adsorbent for treating dye wastewater comprises the following steps:

[0063] (1) Take an appropriate amount of walnut shells and air-dry them at 120°C for 24 hours;

[0064] (2) The walnut shells and dicyandiamide obtained in step (1) were mixed in a mass ratio of 2:1 and ground in a mortar for 30 minutes.

[0065] (3) Put the mixture obtained in step (2) into a vertical tube furnace, and under the protection of nitrogen, raise the temperature in the vertical tube furnace to 50 ° C at a heating rate of 5 ° C / min for carbonization treatment for 3 hours .

[0066] (4) After the material obtained in step (3) was cooled to room temperature, the obtained black powder was mixed with potassium carbonate at a mass ratio of 1:2 and ground in a mortar for 30 minutes.

[0067] (5) The product obtained in step (4) was placed in a vertical quartz tube, and under the protection of nitrogen, the temperature ...

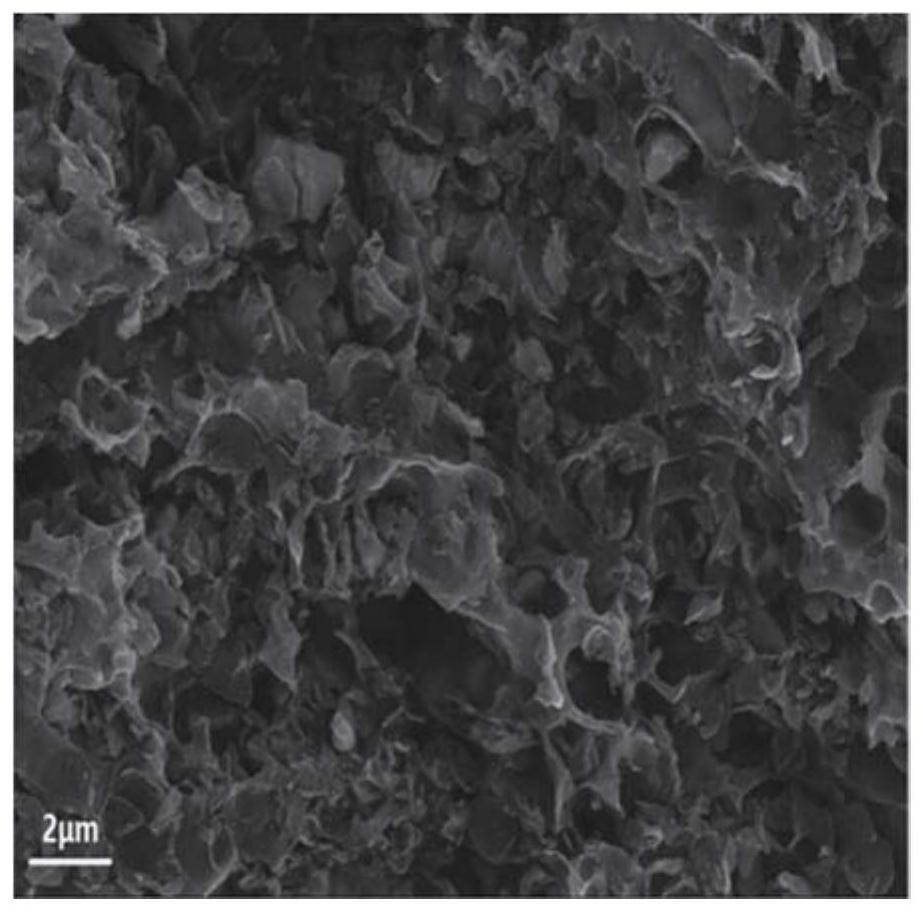

Embodiment 2

[0073] Embodiment 2 A preparation method of a nitrogen-doped porous carbon material adsorbent for treating dye wastewater comprises the following steps:

[0074] (1) Take an appropriate amount of walnut shells and air-dry them at 100°C for 20 hours;

[0075] (2) The walnut shells and dicyandiamide obtained in step (1) were mixed in a mass ratio of 1:1 and ground in a mortar for 20 minutes.

[0076] (3) Put the mixture obtained in step (2) into a vertical tube furnace, and under the protection of nitrogen, raise the temperature in the vertical tube furnace to 550 ° C at a heating rate of 3 ° C / min for carbonization treatment for 1 hour .

[0077] (4) After the material obtained in step (3) was cooled to room temperature, the obtained black powder was mixed with potassium carbonate at a mass ratio of 1:2 and ground in a mortar for 20 minutes.

[0078] (5) The product obtained in step (4) was placed in a vertical quartz tube, and under the protection of nitrogen, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com