Efficient and safe adipic acid synthesis method

A synthesis method and technology of adipic acid, applied in chemical instruments and methods, carboxylate preparation, oxidation preparation of carboxylic acid, etc., can solve the problems of good mixing effect, low reaction liquid holdup, short residence time, etc. The effect of high yield and selectivity, low reaction liquid holdup, and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

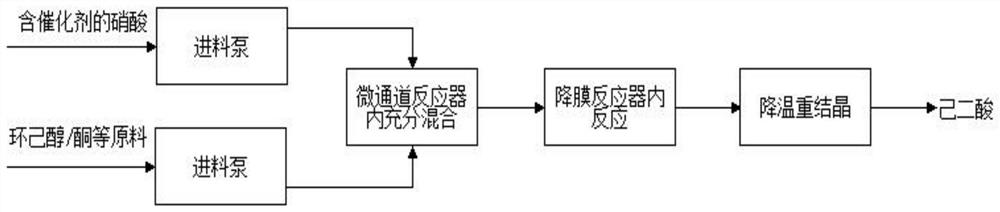

[0028] Such as figure 1 As shown, cyclohexanol and 50% nitric acid (copper 0.25%, vanadium 0.05%) dissolved in catalyst are used as raw materials, and the molar ratio of nitric acid:cyclohexanol is 5:1. The two streams of materials are pumped into the microchannel reactor through the pump, the mixing temperature is 30°C, and the mixing residence time is 20s. The discharged material enters the falling film reactor, the reaction temperature is 80°C, the reaction residence time is 20min, and the reaction pressure is 0.1MPa. The composition of the reaction solution was analyzed by HPLC. The discharged material was cooled, crystallized, suction filtered, and dried to obtain adipic acid. The conversion rate of raw materials was 100%, the selectivity was 96.2%, the content of adipic acid was 99.6%, and the yield of adipic acid was 95.8%.

Embodiment 2

[0030] Such as figure 1 As shown, cyclohexanol and 70% nitric acid (copper 0.25%, vanadium 0.05%) dissolved in catalyst are used as raw materials, and the molar ratio of nitric acid:cyclohexanol is 10:1. The two streams of materials are pumped into the microchannel reactor through the pump, the mixing temperature is 20°C, and the mixing residence time is 40s. The discharged material enters the falling film reactor, the reaction temperature is 80°C, the reaction residence time is 10min, and the reaction is carried out under normal pressure. The composition of the reaction solution was analyzed by HPLC. The discharged material was cooled, crystallized, suction filtered, and dried to obtain adipic acid. The conversion rate of raw materials was 100%, the selectivity was 93.2%, the content of adipic acid was 99.3%, and the yield of adipic acid was 92.5%.

Embodiment 3

[0032] Such as figure 1 As shown, cyclohexanone and 40% nitric acid (copper 0.5%, vanadium 0.25%) dissolved in catalyst are used as raw materials, and the molar ratio of nitric acid:cyclohexanone is 8:1. The two streams of materials are pumped into the microchannel reactor through the pump, the mixing temperature is 10°C, and the mixing residence time is 10s. The discharged material enters the falling film reactor, the reaction temperature is 80°C, the reaction residence time is 30min, and the reaction is carried out under normal pressure. The composition of the reaction solution was analyzed by HPLC, and the discharged material was cooled, crystallized, filtered and dried to obtain adipic acid. The conversion rate of raw materials was 100%, the selectivity was 95.2%, the content of adipic acid was 99.5%, and the yield of adipic acid was 94.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com