Method for preparing far infrared physiotherapy patch through irradiation foaming

A technology of far-infrared and physiotherapy stickers, applied in phototherapy, radiation therapy, treatment, etc., can solve the problems of insufficient softness, softness, low bonding strength, and falling off, and achieve complete drug effects, excellent surface properties, and heat generation. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] refer to figure 1 , this implementation case is a method for preparing far-infrared physiotherapy paste by irradiating foaming, and the preparation method of this kind of far-infrared physiotherapy paste comprises the following steps:

[0027] S1. The ratio of plastic raw materials is according to the weight EVA: 5-100, EPDM: 1-65, PE: 0-25, ADC: 10-25, ceramic powder: 10-70, titanium dioxide powder: 2-15, silicon dioxide Powder: 1-15, dimethyl silicone oil: 0.5-2.0, stearic acid: 0.5-1.5, TAIC: 0.01-5.0, zinc oxide: 2-5 ratio, foaming agent, additives and ceramic powder for mixing , put into the internal mixer and refine into homogeneous rubber balls;

[0028] S2. Put the rubber balls of S1 on the open mill to plasticize the wrapping roll, add zinc oxide, and evenly knead into a sheet by making a triangular wrapping process;

[0029] S3, irradiating the sheet of S2 with electron accelerator rays to cross-link the sheet;

[0030] S4, the cross-linked sheet of S3 is h...

Embodiment example 1

[0039] A method for preparing self-adhesive far-infrared physiotherapy paste by irradiation foaming, comprising the following steps:

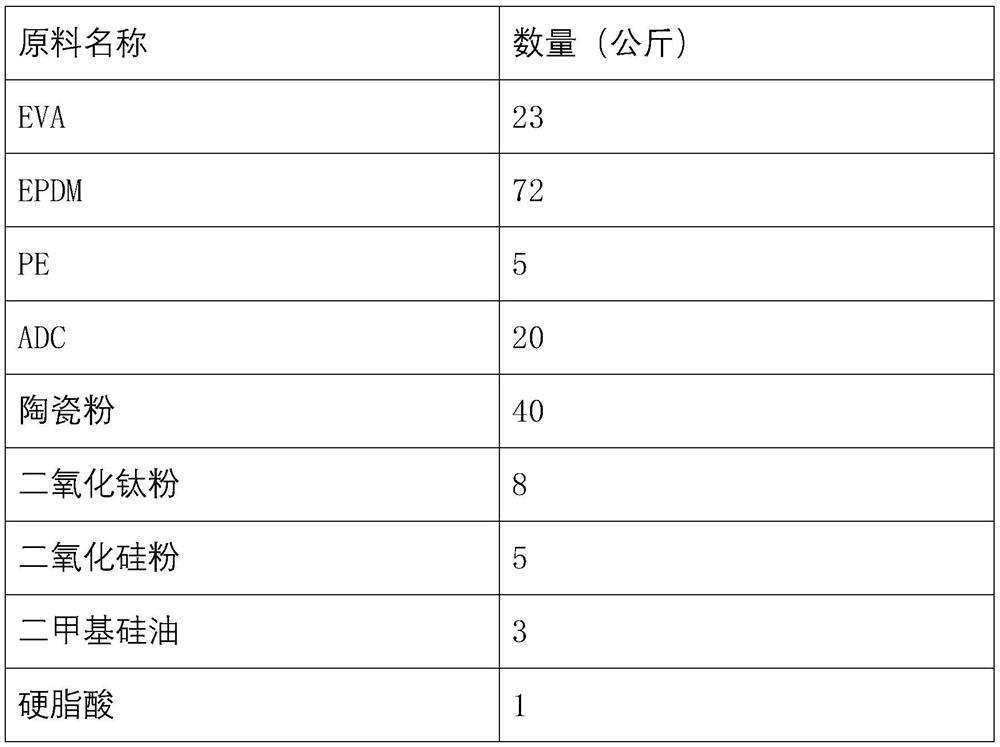

[0040] 1) Weigh the materials in the following table for later use;

[0041]

[0042]

[0043] 2) Put all the raw materials except zinc oxide in step 1) into the internal mixer for mixing, when the material temperature reaches 150°C, count for 5 minutes, and unload after refining into homogeneous rubber balls;

[0044] 3) Put the high-temperature rubber balls in step 2) on the open mill to cool down to below 100°C; then slowly disperse the zinc oxide powder into the film, and make a triangle bag process to make the zinc oxide powder evenly mixed into the film;

[0045] 4) subjecting the sheet in step 3) to an irradiation cross-linking process with a dose of 30 kGy of electron beam rays to become a cross-linked sheet;

[0046]5) The cross-linked sheet in step 4) is foamed by a flat vulcanizer at 170°C for 25 minutes to become a foamed she...

Embodiment 2

[0049] A method for preparing self-adhesive far-infrared physiotherapy patch by irradiation foaming, comprising the following steps:

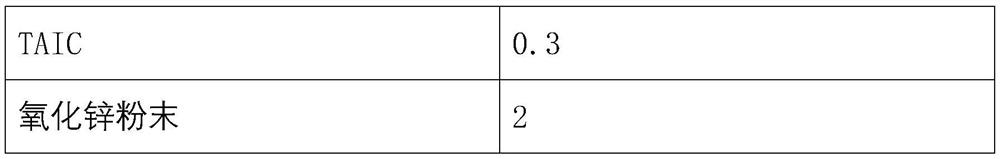

[0050] 1) Weigh the materials in the following table for later use;

[0051]

[0052]

[0053] 2) Put all the other raw materials in step 1) except zinc oxide into the internal mixer for mixing, when the temperature of the materials reaches 160°C, count for 10 minutes, and unload after refining into homogeneous rubber balls;

[0054] 3) Put the high-temperature rubber balls in step 2) on the open mill to cool down to below 100°C; then slowly disperse the zinc oxide powder into the film, and make a triangle bag process to make the zinc oxide powder evenly mixed into the film;

[0055] 4) subjecting the sheet in step 3) to an irradiation cross-linking process with a dose of 35kGy of electron beam rays to become a cross-linked sheet;

[0056] 5) The cross-linked sheet in step 4) is foamed by a flat vulcanizer at 160° C. for 25 minutes to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com