Graphene-loaded transition metal compound, preparation method thereof and application of graphene-loaded transition metal compound in catalytic oxidation fuel oil desulfurization

A transition metal and graphene technology, applied in the refining of oxygen-containing compounds, catalysts for physical/chemical processes, chemical instruments and methods, etc., can solve the problems of low removal rate of sulfur-containing compounds, poor reusability, and difficulty in complete removal. , to achieve the effect of good reusability, convenient separation and recovery, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Polyethyleneimine modified graphene oxide loaded P 2 W 18 Composite catalyst P 2 W 18 -Preparation of PEI / GO: The steps are as follows: add 0.05 g polyethyleneimine-modified graphene oxide to 10 mL of water, adjust the pH value of the solution to 4 with 4 mol / L hydrochloric acid solution, and make it A liquid, 0.2 g P 2 W 18 Dissolve in 11 mL deionized water, adjust the pH value of the solution to 4.7 with 4 mol / L hydrochloric acid solution, and make it B liquid; slowly add liquid B dropwise into liquid A, adjust the pH value of the solution to 4.5 with 4 mol / L hydrochloric acid solution, and store at room temperature React for 10 hours, centrifuge at 4000 rpm (25°C) for about 10 minutes to obtain a solid product, wash with deionized water several times, and vacuum freeze-dry at -55°C for 48 hours to obtain polyethyleneimine-modified graphene oxide-supported P 2 W 18 Composite catalyst (P 2 W 18 -PEI / GO).

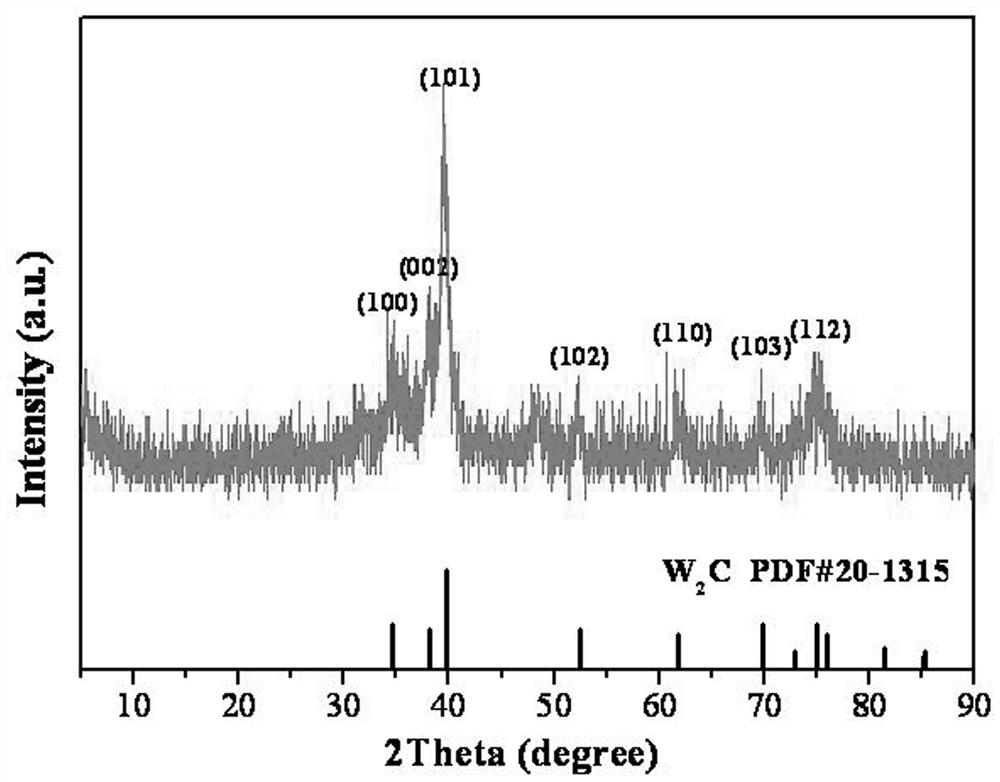

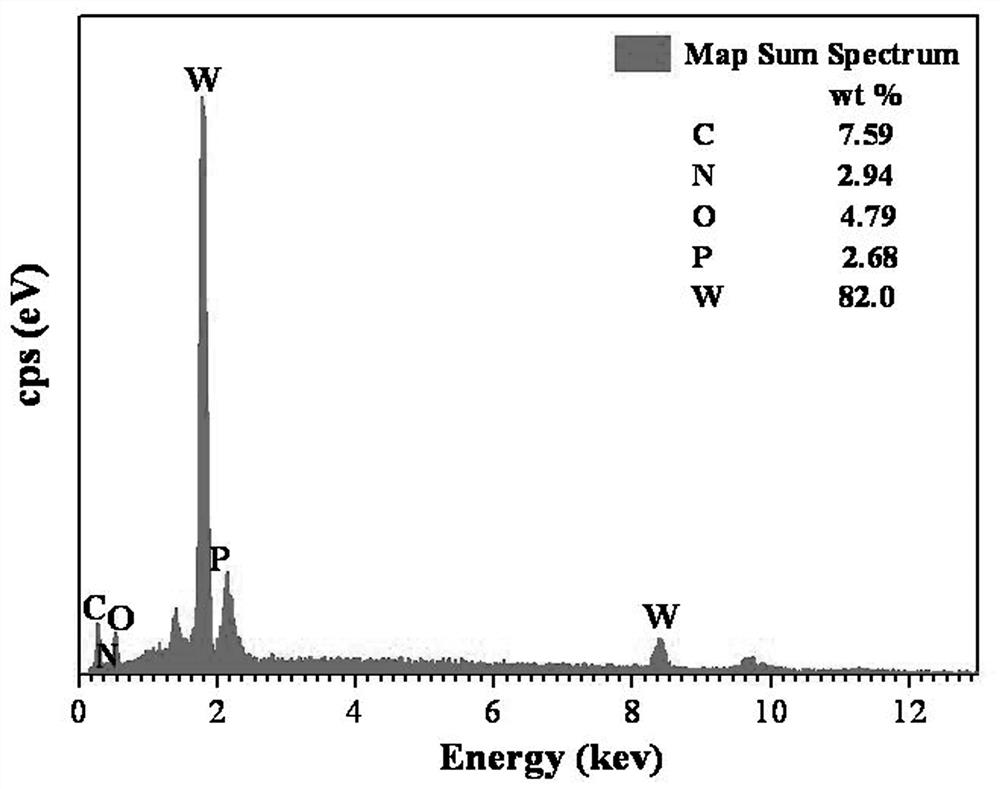

[0040] Preparation of graphene-supported tun...

Embodiment 2

[0042] Example 2: Polyethyleneimine modified graphene oxide loaded PW 12 Composite catalyst PW 12 -Preparation of PEI / GO: The steps are as follows: add 0.1g of polyethyleneimine-modified graphene oxide to 20 mL of water, adjust the pH of the solution to 4.1 with 4 mol / L hydrochloric acid solution, and make it A solution, 0.6g PW 12 Dissolve in 10 mL deionized water to form B solution; slowly drop B solution into A solution, adjust the pH value of the solution to 4.8 with 4 mol / L hydrochloric acid solution, react at room temperature for 10 hours, and centrifuge at 4000 rpm (25°C) for about 15 minutes , to obtain a solid product, washed with deionized water several times, and vacuum freeze-dried at -55°C for 48 hours to obtain polyethyleneimine-modified graphene oxide-supported PW 12 Composite catalyst (PW 12 -PEI / GO).

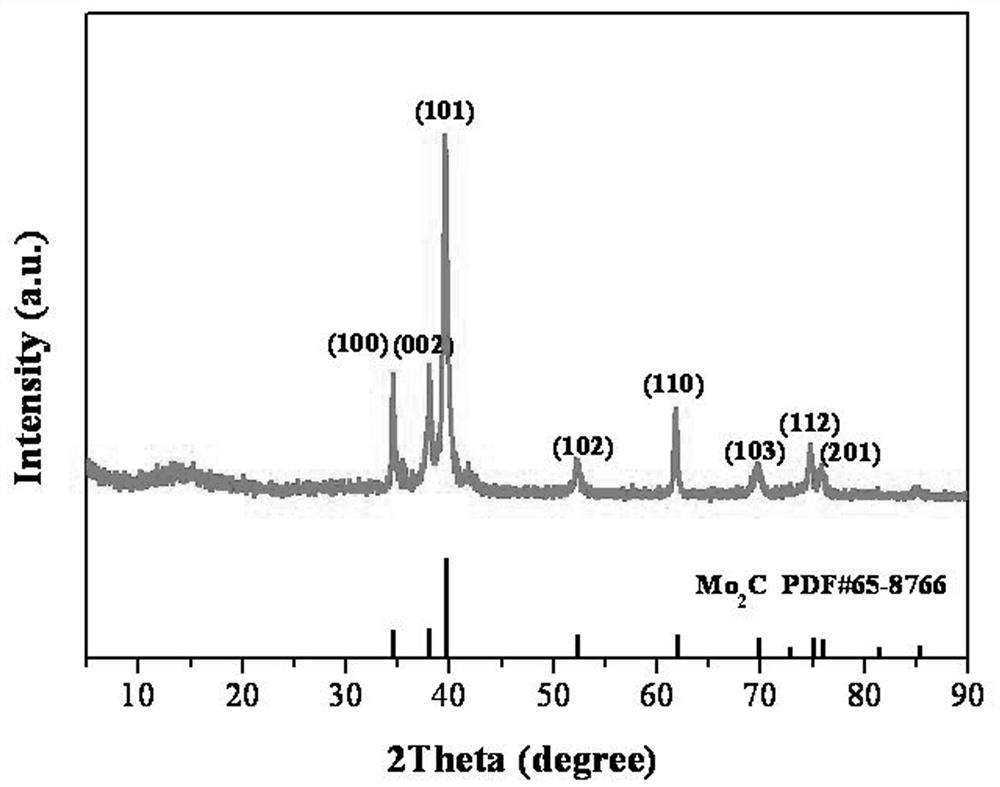

[0043] Preparation of graphene-supported tungsten carbide heterogeneous catalyst: the steps are as follows: polyethyleneimine-modified graphene oxide-support...

Embodiment 3

[0045] Example 3: Polyethyleneimine modified graphene oxide supported SiW 12 Composite catalyst SiW 12- Preparation of PEI / GO: The steps are as follows: add 0.15 g of polyethyleneimine-modified graphene oxide to 30 mL of water, adjust the pH of the solution to 4.3 with 4 mol / L hydrochloric acid solution, and make it A solution, 0.6 g SiW 12 Dissolve in 15mL deionized water to form B solution; slowly drop B solution into A solution, adjust the pH value of the solution to 5 with 4 mol / L hydrochloric acid solution, react at room temperature for 12 hours, and centrifuge at 4000rpm (25°C) for about 12min to obtain The solid product was washed several times with deionized water, and then vacuum freeze-dried at -55°C for 48 hours to obtain polyethyleneimine-modified graphene oxide-supported SiW 12 Composite catalyst (SiW 12 -PEI / GO).

[0046] The preparation of graphene-supported tungsten-doped tungsten nitride heterogeneous catalyst: the steps are as follows: polyethyleneimine-mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com