Desalination treatment method for reverse osmosis concentrated water

A reverse osmosis concentrated water and treatment method technology, applied in the field of sewage treatment, can solve the problems of acid-base waste liquid, polarization scaling, and complicated operation, so as to reduce scaling ability and corrosion ability, realize recycling, The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

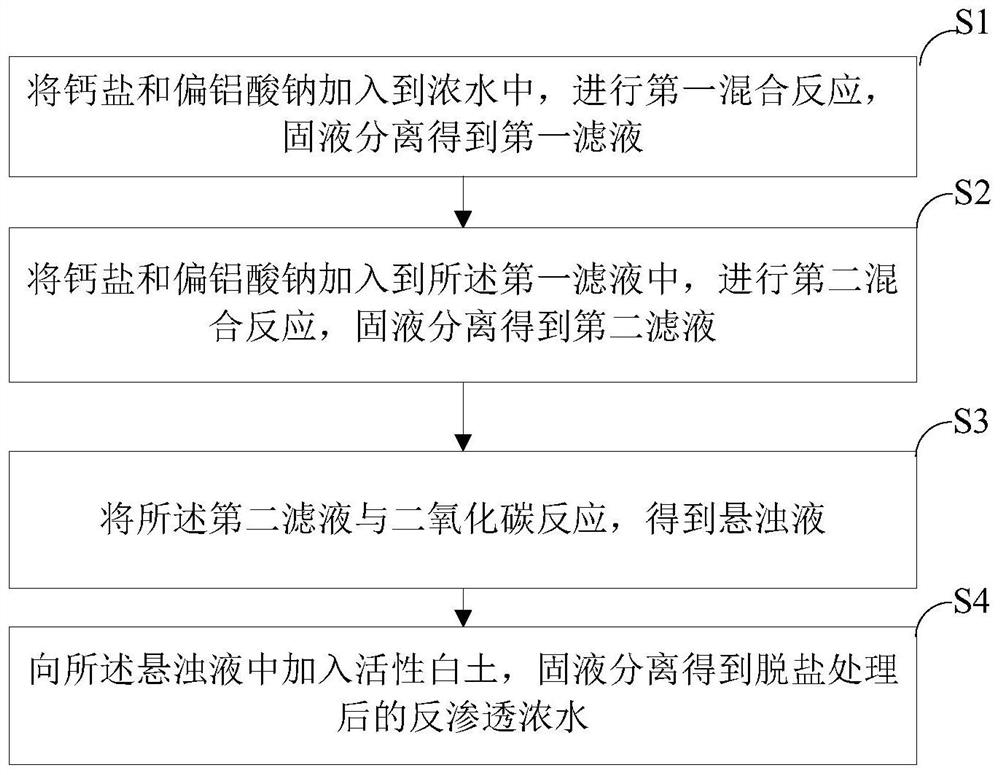

Method used

Image

Examples

Embodiment 1

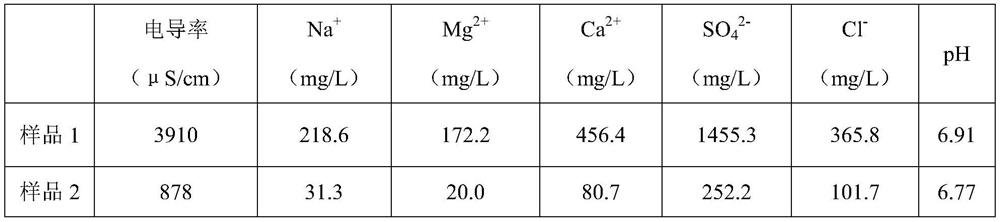

[0055] The concentrated water sample 1 in table 1 is processed as follows:

[0056] (1) Add calcium oxide and sodium metaaluminate to reverse osmosis concentrated water (the molar ratio of calcium oxide, sodium metaaluminate and sulfate ions in the solution is 8:2:1), and stir at 25°C Reaction 120min, suspension is filtered, obtains the filtrate that removes sulfate ion;

[0057] (2) Continue to add calcium oxide and sodium metaaluminate to the filtrate (the molar ratio of calcium oxide, sodium metaaluminate and chloride ions in the solution is 6:2:1), and stir for 120 minutes at 25°C , the suspension is filtered to obtain the filtrate for removing chloride ions;

[0058] (3) Use an air pump to blow air into the filtrate for 2 hours to remove residual calcium and magnesium ions in the solution;

[0059] (4) Add activated clay to the solution according to the addition amount of 50g / L, stir and react for 2h, remove part of the sodium ions in the solution by ion exchange and ne...

Embodiment 2

[0061] The concentrated water sample 1 in table 1 is processed as follows:

[0062] (1) Add calcium hydroxide and sodium metaaluminate to reverse osmosis concentrated water (the molar ratio of calcium hydroxide, sodium metaaluminate and sulfate ions in the solution is 8:2:1), at 25°C , stirring and reacting for 80min, the suspension was filtered to obtain the filtrate for removing sulfate ions;

[0063] (2) Continue to add calcium hydroxide and sodium metaaluminate to the filtrate (the molar ratio of calcium hydroxide, sodium metaaluminate and chloride ions in the solution is 6:2:1), and stir at 25°C After reacting for 80min, the suspension was filtered to obtain the filtrate from which chloride ions were removed;

[0064] (3) Use an air pump to blow air into the filtrate for 3 hours to remove residual calcium and magnesium ions in the solution;

[0065] (4) Add activated clay to the solution according to the addition amount of 50g / L, stir and react for 2h, remove part of th...

Embodiment 3

[0067] The concentrated water sample 1 in table 1 is processed as follows:

[0068] (1) Add calcium oxide and sodium metaaluminate to reverse osmosis concentrated water (the molar ratio of calcium oxide, sodium metaaluminate and sulfate ions in the solution is 10:4:1), and stir at 35°C Reaction 40min, suspension is filtered, obtains the filtrate that removes sulfate ion;

[0069] (2) Continue to add calcium oxide and sodium metaaluminate to the filtrate (the molar ratio of calcium oxide, sodium metaaluminate and chloride ions in the solution is 8:4:1), and stir for 40 minutes at 35°C , the suspension is filtered to obtain the filtrate for removing chloride ions;

[0070] (3) Use an air pump to blow air into the filtrate for 4 hours to remove residual calcium and magnesium ions in the solution;

[0071] (4) Add activated clay to the solution according to the addition amount of 50g / L, stir and react for 2h, remove part of the sodium ions in the solution by ion exchange and neu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com