Method for preparing high-purity 2, 4-dinitrochlorobenzene through nitration of o-nitrochlorobenzene

A technology of dinitrochlorobenzene and o-nitrochlorobenzene, which is applied in the field of preparation of high-purity 2,4-dinitrochlorobenzene by nitration of o-nitrochlorobenzene, can solve the problem of product purity not meeting requirements, nitro compounds Easy to decompose, the high cost of the chlorobenzene method, etc., to achieve the effect of increasing added value, protecting the environment and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

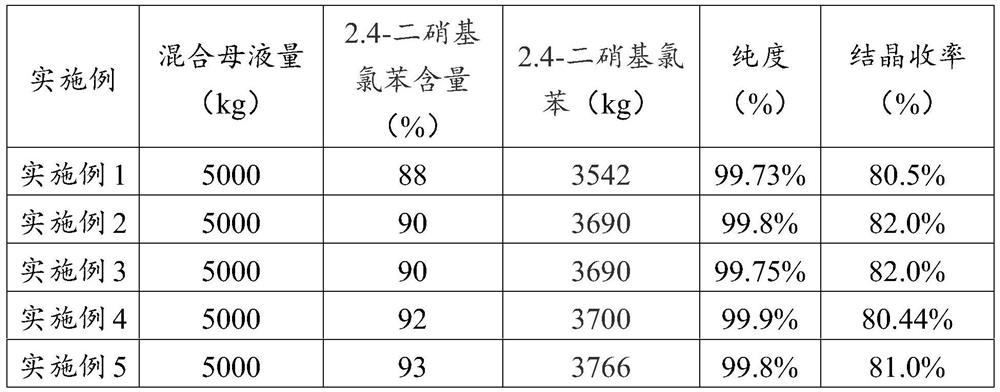

Examples

Embodiment 1

[0026] Embodiment 1: Nitrification reaction

[0027] With a certain concentration of N 2 o 5 / HNO 3 The solution is a nitrating agent, o-nitrochlorobenzene is used as a raw material, and a mixed mother liquor is obtained by nitration. The mixed mother liquor includes 2.4-dinitrochlorobenzene and 2.6-dinitrochlorobenzene, and the proportion of the nitrating agent is 0.35gN 2 o 5 / 10mlHNO 3 , the nitration reaction temperature is 48°C, the nitration reaction time is 90min, and the ratio of the mass g of o-nitrochlorobenzene to the volume ml of the nitrating agent is 1:3.

Embodiment 2

[0028] Embodiment 2: Nitrification reaction

[0029] With a certain concentration of N 2 o 5 / HNO 3 The solution is a nitrating agent, o-nitrochlorobenzene is used as a raw material, and a mixed mother liquor is obtained by nitration. The mixed mother liquor includes 2.4-dinitrochlorobenzene and 2.6-dinitrochlorobenzene, and the proportion of the nitrating agent is 0.45gN 2 o 5 / 10mlHNO 3 , the nitration reaction temperature is 55°C, the nitration reaction time is 60min, and the ratio of the mass g of o-nitrochlorobenzene to the volume ml of the nitrating agent is 1:5.

Embodiment 3

[0030] Embodiment 3: Nitrification reaction

[0031] With a certain concentration of N 2 o 5 / HNO 3 The solution is a nitrating agent, o-nitrochlorobenzene is used as a raw material, and a mixed mother liquor is obtained by nitration. The mixed mother liquor includes 2.4-dinitrochlorobenzene and 2.6-dinitrochlorobenzene, and the proportion of the nitrating agent is 0.4gN 2 o 5 / 10mlHNO 3 , The nitration reaction temperature is 52°C, the nitration reaction time is 90min, and the ratio of the mass g of o-nitrochlorobenzene to the volume ml of the nitrating agent is 1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com