Method for preparing high-purity lactide based on catalytic cracking of organic guanidine complex

A catalytic cracking, organic guanidine technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve problems affecting product yield, high reaction temperature, environmental pollution, etc. Achieve the effect of no cytotoxicity, simple preparation process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

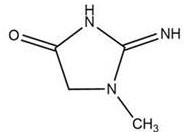

[0034] (1) Mix 0.1mol organic guanidine (CR) and 0.1mol ZnCl 2 Dissolve in 150ml of water and 150ml of methanol respectively, add the zinc chloride methanol solution into the reactor, slowly add the organic guanidine aqueous solution dropwise under continuous stirring, and condense and reflux at 60°C for 8 hours after the dropwise addition; centrifuge, wash, and dry That is, the organic guanidine complex CRZnCl 2 , yield 82.6%.

[0035] (2) Add lactic acid and ZnO (mass ratio to lactic acid: 1:1000) into the reactor, polycondense at 150°C and 1kPa for 8 hours, slowly distill out free water in the reaction system, and finally obtain lactic acid oligomers, molecular weight for 1880.

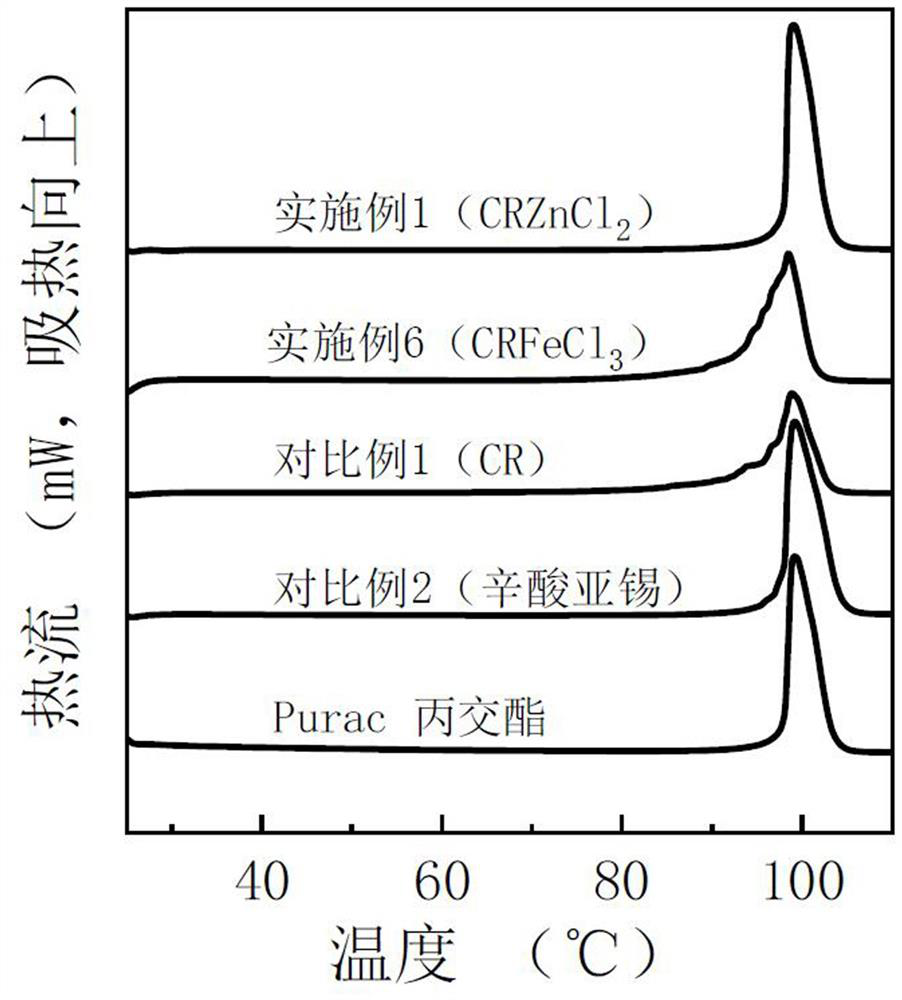

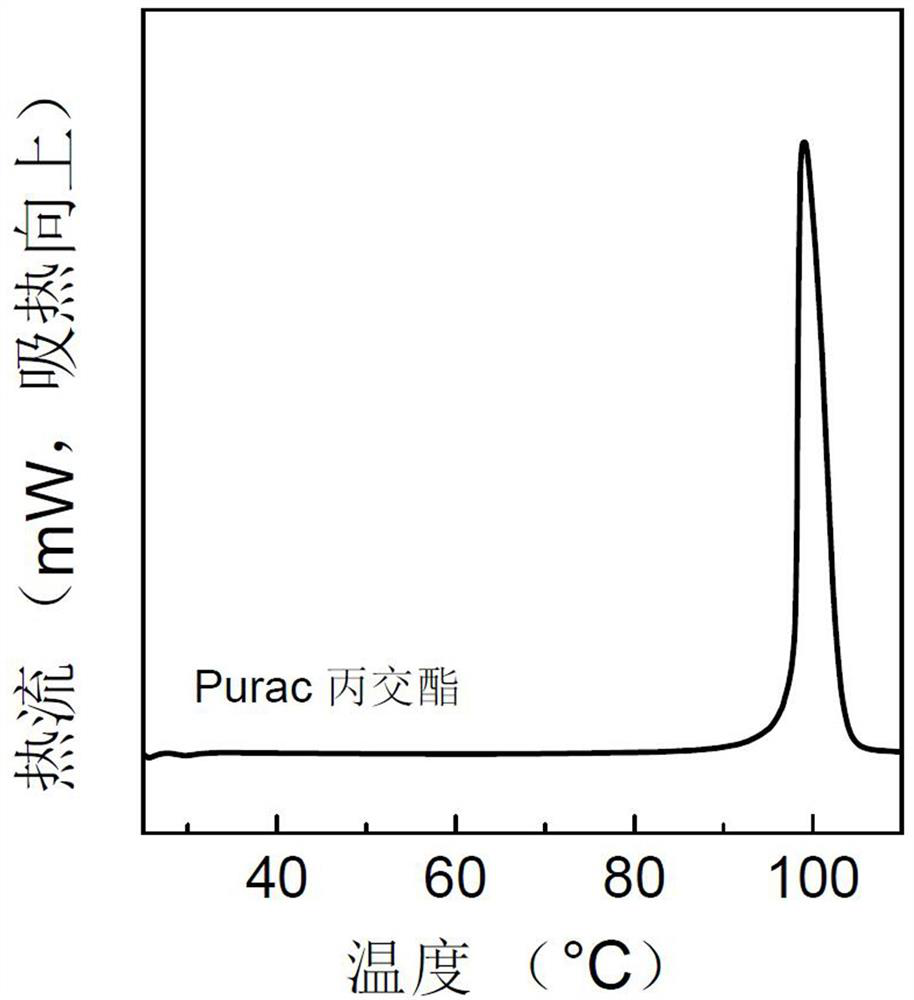

[0036] Adding organic guanidine complex CRZnCl to lactic acid oligomer 2 (The mass ratio of the oligomer to the oligomer is 1:1000), distilled under reduced pressure at 200°C and a vacuum of 0.5kPa for 2h, and collected white crude lactide with a yield of 91.3%. The chemical purity of the produ...

Embodiment 2

[0039] (1) 0.1mol organic guanidine (CR) and 0.1mol Zn(OAc) 2 Dissolve in 150ml of water and 150ml of ethanol respectively, add zinc acetate ethanol solution into the reactor, slowly add organic guanidine aqueous solution dropwise with continuous stirring, after the dropwise addition is completed, condense and reflux for 12h at 30 °C; centrifuge, wash, and dry. Obtained organic guanidine complex CRZn(OAc) 2 , the yield is 86.5%.

[0040] (2) Add lactic acid and ZnO (the mass ratio to lactic acid is 1:1500) into the reactor, polycondensate at 160 ° C and 2 kPa for 6 hours, and slowly evaporate the free water in the reaction system, and finally obtain lactic acid oligomers with molecular weight. is 1700.

[0041] Addition of organic guanidine complex CRZn(OAc) to lactic acid oligomers 2 (the mass ratio to oligomer is 1:800), under reduced pressure distillation at 190 ° C and a vacuum of 0.4 kPa for 1.5 h, white crude lactide is collected, and the yield is 80.2%. The chemical...

Embodiment 3

[0044] (1) 0.1mol organic guanidine (CR) and 0.1mol Zn(OLa) 2 Dissolve in 150ml of water and 150ml of ethanol respectively, add zinc lactate ethanol solution into the reactor, slowly add organic guanidine aqueous solution dropwise with continuous stirring, after the dropwise addition is completed, condensate and reflux for 10h at 50 °C; centrifuge, wash, and dry. Obtained organic guanidine complex CRZn(OLa) 2 , the yield was 90.6%.

[0045] (2) Add lactic acid and ZnO (mass ratio to lactic acid is 1:1800) into the reactor, polycondensate at 120 ° C and 2 kPa for 5 h, the free water in the reaction system is slowly distilled out, and finally lactic acid oligomers are obtained. is 1330.

[0046] Adding the prepared organic guanidine complex CRZn(OLa) to lactic acid oligomers 2 (1:1200 mass ratio to oligomer), vacuum distillation was carried out at 170 ° C and a vacuum degree of 0.2 kPa for 2.5 h, and white crude lactide was collected, with a yield of 85.5%. The chemical puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com