Method for preparing high-purity trimethyl antimony from trimethyl aluminum and antimony trichloride

A technology of trimethyl antimony and trimethyl aluminum, applied in the direction of antimony organic compounds, etc., can solve the problems of long time, difficult trimethyl antimony, dangerous to handle, etc., and achieves high safety, simple operation and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

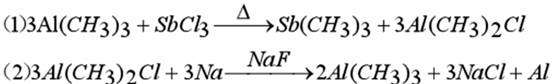

Method used

Image

Examples

example 1

[0021] This embodiment provides a method for preparing high-purity trimethylantimony by using trimethylaluminum and antimony trichloride, the steps are as follows:

[0022] Step 1: Take 456.5g or 2.0mol of antimony trichloride, first heat it at 45°C and dry it in vacuum under absolute pressure, add the above antimony trichloride into a 2L four-necked bottle in an anhydrous and oxygen-free environment, and set up a normal pressure reflux device , keep the airtightness good, and start stirring;

[0023] Step 2: Set the cold oil in the condenser tube to -10±1°C, pass through the cold oil, and slowly add 432.5g or 6.0mol of trimethylaluminum dropwise when the temperature of the cold oil drops to the set temperature. Aluminum from slow to fast, after the addition of trimethylaluminum, adjust the temperature to 95°C and stir for 5 hours;

[0024] Step 3: Slowly increase the temperature of the reaction bottle, the maximum temperature is controlled at 120°C, and the temperature at th...

example 2

[0029] This embodiment provides a method for preparing high-purity trimethylantimony by using trimethylaluminum and antimony trichloride, the steps are as follows:

[0030] Step 1: Take 684.5g, that is, 3.0mol of antimony trichloride, and first heat it to 45°C for absolute pressure vacuum drying, add the above antimony trichloride into a 2L four-necked bottle in an anhydrous and oxygen-free environment, set up an atmospheric distillation device, and gas Good tightness, start stirring;

[0031] Step 2: Set the cold oil in the condenser tube to -10±1°C, pass through the cold oil, and slowly add 648.5g or 9.0mol of trimethylaluminum dropwise when the temperature of the cold oil drops to the set temperature. Aluminum from slow to fast, after the trimethylaluminum is added dropwise, the temperature is raised to 96°C and the reaction is stirred for 5 hours;

[0032] Step 3: Slowly increase the temperature of the reaction bottle, the maximum temperature is controlled at 120°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com