Calcium-based brine polymer strong-inhibition environment-friendly drilling fluid base fluid, drilling fluid as well as preparation and application of drilling fluid

A drilling fluid and polymer technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of drilling fluid not flowing, environmental protection is difficult to meet standards, drilling fluid rapid slurrying, etc., to achieve the ability to inhibit plugging Strong, keep the well wall clean and prevent the coal seam from collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0149] This embodiment provides a calcium-based brine polymer strong inhibition environment-friendly drilling fluid base fluid, denoted as 1# base fluid, wherein, the total volume of pre-hydrated sodium bentonite slurry is used as the calculation basis, and the base fluid includes pre-hydrated sodium bentonite slurry Sodium hydrate bentonite slurry, 2wt / v% high temperature resistant starch fluid loss reducer SHR-1, 0.6wt / v% sulfonate copolymer fluid loss reducer DSP-1, 0.6wt / v% low viscosity copolymer PANS flow regulator, 7wt / v% calcium-based oligosalt and 0.3wt / v% NaOH, wherein the concentration of sodium bentonite in the prehydrated sodium bentonite slurry is 3wt / v%;

[0150] Wherein, the calcium-based oligosalt is composed of CaCl 2 , CaCO 3 The compound formed after mixing with low-viscosity carboxymethyl cellulose sodium salt, based on the total weight of the compound as 100%, it comprises 40wt% low-viscosity carboxymethyl cellulose sodium salt, 50wt% CaCI 2 and 10 wt%...

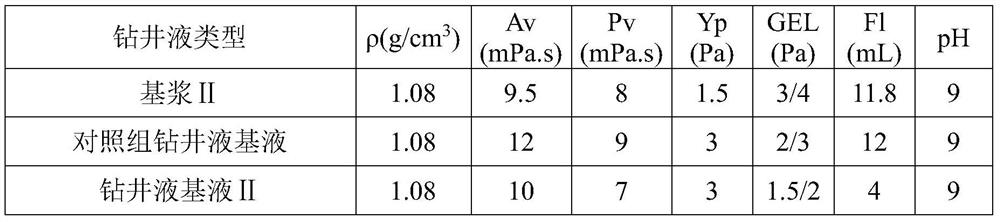

Embodiment 2

[0152] This embodiment provides a calcium-based brine polymer strong inhibition environment-friendly drilling fluid base fluid, which is denoted as 2# base fluid, wherein the total volume of prehydrated sodium bentonite slurry is used as the calculation basis, and the base fluid includes pre-hydrated sodium bentonite slurry. Sodium hydrate bentonite slurry, 2wt / v% high temperature resistant starch fluid loss reducer SHR-1, 1wt / v% sulfonate copolymer fluid loss reducer DSP-1, 1wt / v% low viscosity copolymer PANS flow regulator, 10wt / v% calcium-based oligosalt and 0.3wt / v% NaOH, wherein the concentration of sodium bentonite in the prehydrated sodium bentonite slurry is 2wt / v%;

[0153] Wherein, the calcium-based oligosalt is composed of CaCl 2 , CaCO 3 The compound formed after mixing with low-viscosity carboxymethyl cellulose sodium salt, based on the total weight of the compound as 100%, it comprises 40wt% low-viscosity carboxymethyl cellulose sodium salt, 50wt% CaCI 2 and 1...

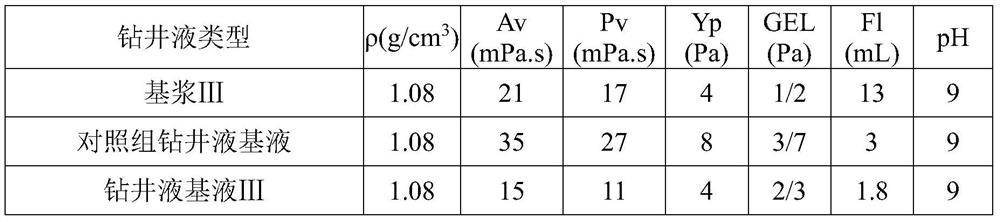

Embodiment 3

[0155] This embodiment provides a calcium-based brine polymer strong inhibition environment-friendly drilling fluid base fluid, denoted as 3# base fluid, wherein, taking the total volume of clean water as the basis for calculation, the base fluid includes clean water, 0.2wt / v %Na 2 CO 3 , 3wt / v% sodium bentonite, 2wt / v% high temperature resistant starch fluid loss reducer SHR-1, 1.5wt / v% sulfonate copolymer fluid loss reducer DSP-1, 1.5wt / v% Low-viscosity copolymer PANS flow regulator, 10wt / v% calcium-based oligosalt and 0.3wt / v% NaOH;

[0156] Wherein, the calcium-based oligosalt is composed of CaCl 2 , CaCO 3 The compound formed after mixing with low-viscosity carboxymethyl cellulose sodium salt, based on the total weight of the compound as 100%, it comprises 40wt% low-viscosity carboxymethyl cellulose sodium salt, 50wt% CaCI 2 and 10 wt% CaCO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com