Large-particle high-brightness nitride red fluorescent powder as well as preparation method and application thereof

A red phosphor, nitride technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of reducing the luminous efficiency of white light, low luminous intensity, harmful to human body, etc., to improve the luminous performance, and the preparation method is simple , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

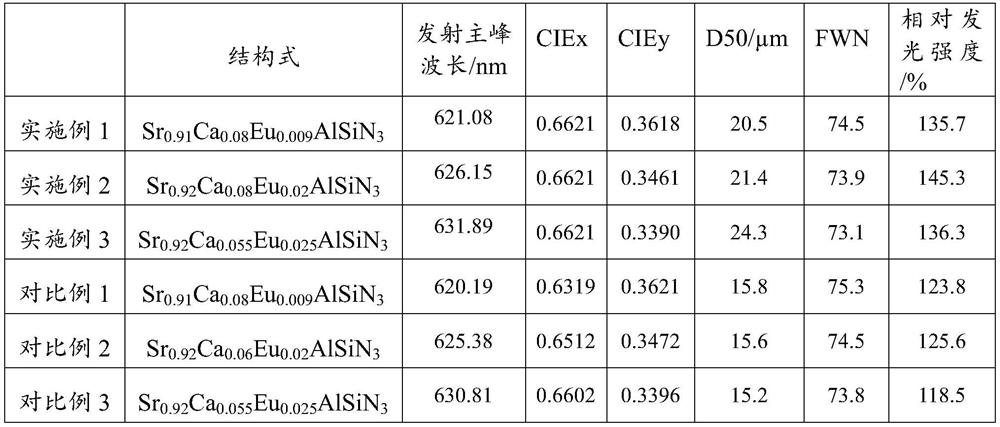

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a nitride red fluorescent powder, the structural formula of which is Sr 0.91 Ca 0.08 Eu 0.009 AlSiN 3 , including the following steps:

[0033] (1) Accurately weigh 121.6g Sr 3 N 2 , 5.448g Ca 3 N 2 , 64.444g Si 3 N 4 , 2.592g EuF 3 , 56.492gAlN, mixed evenly under the protective atmosphere of argon gas in the glove box, the materials mixed together were mixed by a high-speed crusher for 5 minutes, poured out of the crusher and passed through a 150-mesh nylon sieve, and then mixed twice by a high-speed crusher to obtain the first mixed material;

[0034](2) Get 200g of the first mixed material and loosely pack it into a molybdenum crucible, quickly move the molybdenum crucible filled with the first mixed material into the graphite carbon box of the sintering furnace, close the sintering furnace door, vacuumize, pour in argon, and again Vacuumize, repeat the operation three times to replace the gas in the sinteri...

Embodiment 2

[0039] This embodiment provides a method for preparing a nitride red fluorescent powder, the structural formula of which is Sr 0.92 Ca 0.08 Eu 0.02 AlSiN 3 , including the following steps:

[0040] (1) Accurately weigh 121.76g Sr 3 N 2 , 4.047g Ca 3 N 2 , 63.829g Si 3 N 4 , 5.705g EuF 3 , 55.953g AlN, mixed evenly under the protective atmosphere of argon in the glove box, mixed the mixed materials with a high-speed crusher for 5 minutes, poured out the crusher and passed through a 150-mesh nylon sieve, and then used the high-speed crusher to mix twice, obtaining the first mixed material;

[0041] (2) Get 200g of the first mixed material and loosely pack it into a molybdenum crucible, quickly move the molybdenum crucible filled with the first mixed material into the graphite carbon box of the sintering furnace, close the sintering furnace door, vacuumize, pour in argon, and again Vacuumize, repeat the operation three times to replace the gas in the sintering furnace;...

Embodiment 3

[0046] This embodiment provides a method for preparing a nitride red fluorescent powder, the structural formula of which is Sr 0.92 Ca 0.055 Eu 0.025 AlSiN 3 , including the following steps:

[0047] (1) Accurately weigh 121.391g Sr 3 N 2 , 3.699 g Ca 3 N 2 , 63.635g Si 3 N 4 , 7.109 g EuF 3 , 55.782g AlN, mixed evenly under the protective atmosphere of argon in the glove box, mixed the mixed materials with a high-speed crusher for 5 minutes, poured out the crusher and passed through a 150-mesh nylon sieve, and then used the high-speed crusher to mix twice, obtaining the first mixed material;

[0048] (2) Get 200g of the first mixed material and loosely pack it into a molybdenum crucible, quickly move the molybdenum crucible filled with the first mixed material into the graphite carbon box of the sintering furnace, close the sintering furnace door, vacuumize, pour in argon, and again Vacuumize, repeat the operation three times to replace the gas in the sintering fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com