Preparation method of insulation/tritium permeation resistance composite coating on surface of vanadium alloy

A technology of composite coating and vanadium alloy, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problems such as the decline of tritium resistance effect, the change of material mechanical properties, and the deviation from material design parameters, etc., to achieve Improvement of tritium blocking effect and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

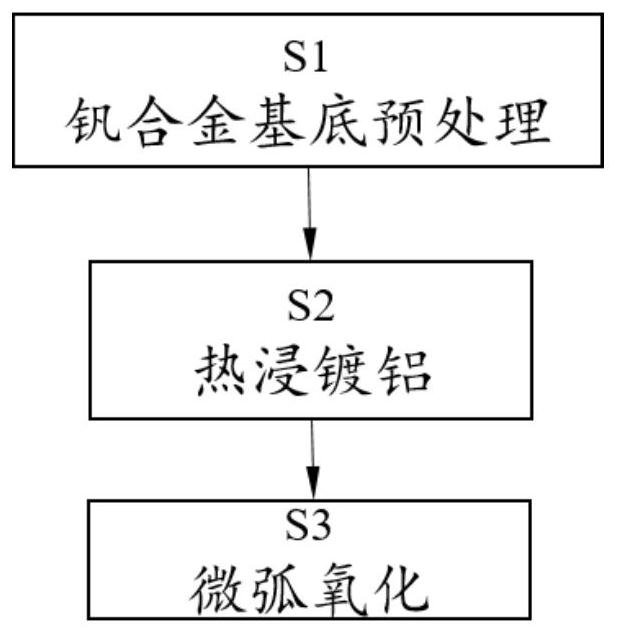

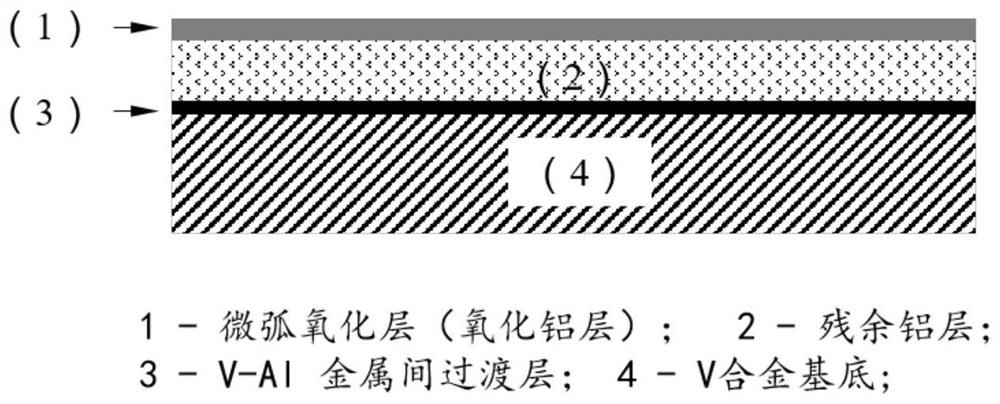

[0027] figure 1 A schematic diagram of a method for preparing a tritium-resistant insulating coating on the surface of a vanadium alloy according to an embodiment of the present invention is shown. Preparation methods include:

[0028] Step S1, pretreating the vanadium alloy substrate. Preferably, the pretreatment method used is grinding the vanadium alloy material, followed by alkali washing, then washing with deionized water, then pickling, and then washing with deionized water for use.

[0029] Step S2, performing hot-dip aluminum plating on the pretreated vanadium alloy substrate. Preferably, the aluminum plating agent is pure aluminum, the used plating flux is an aqueous solution of fluorine-containing salt, the aluminum plating treatment is carried out under the protection of an inert gas, and the plating flux treatment and preheating treatment are performed before aluminum plating.

[0030] Step S3, performing micro-arc oxidation treatment on the vanadium alloy mater...

Embodiment 1

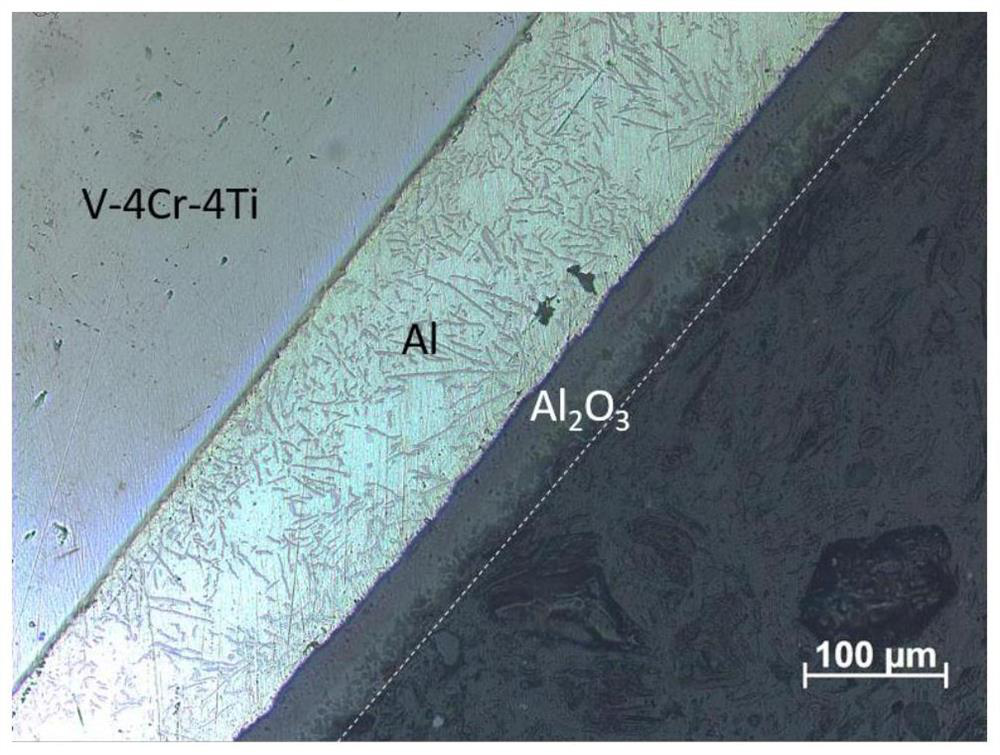

[0033] Using V-4Cr-4Ti alloy as the base material, the surface of the vanadium alloy material is mechanically polished and smoothed, successively using 150#, 240#, 300#, 600# sandpaper to polish and smooth; after that, use Na 2 CO 3 Mixed with NaOH aqueous solution for alkaline washing; then use deionized water to clean; then use dilute hydrochloric acid aqueous solution to pickle; then use deionized water to wash, dry for use.

[0034] Configure the fluxing agent for hot-dip aluminum plating, the fluxing agent used is potassium fluorozirconate (K 2 ZrF 6 ) salt-saturated aqueous solution, the flux is kept at 80°C; the pretreated vanadium alloy is soaked in the flux for 15 minutes; and then dried with cold air to prepare for aluminum plating.

[0035] Hot-dip aluminum plating is carried out in a glove box filled with 1 atm argon as a protective gas, and the glove box is equipped with environmental temperature control facilities; the plating agent is 99.97% high-purity alumin...

Embodiment 2

[0040] The vanadium alloy matrix sample was pretreated according to the same method as in Example 1, followed by flux plating and hot-dip aluminum plating, and finally an electrolyte was prepared to perform micro-arc oxidation treatment on the aluminum-plated vanadium alloy matrix. The difference is that the flux used in this example is 10g / L KF aqueous solution, the temperature of the aluminum liquid used for aluminum plating is 780°C, and the aluminum plating time is 1min.

[0041] Through the above steps, a composite film vanadium alloy material with an oxide layer thickness of 38 μm was finally obtained, marked as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com