Low-surface-energy anti-adhesion nickel-titanium wire and processing method thereof

A technology with low surface energy and processing methods, applied in the field of medical devices, can solve problems such as susceptibility to infection, granulation hyperplasia, protein adhesion, etc., and achieve the effect of avoiding blockage and infection problems, and avoiding introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this example, a pulsed laser processing method was used to prepare a micro-nano structure with anti-fibroblast adhesion, anti-protein adhesion and anti-infection functions on the surface of nickel-titanium wire. The specific steps are as follows:

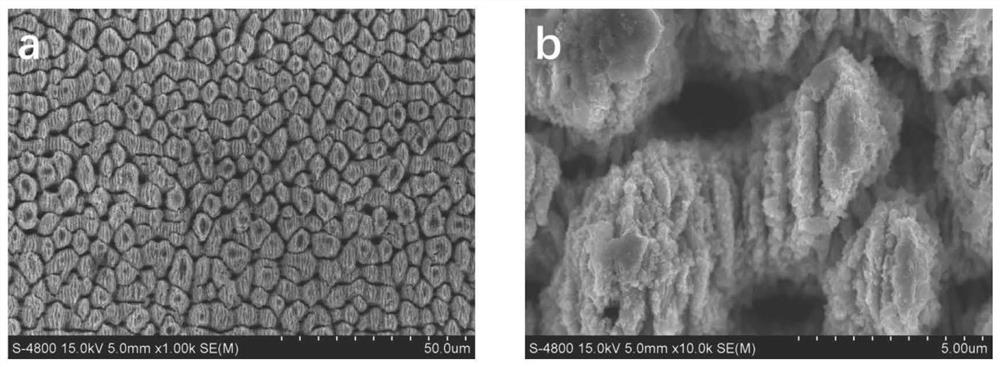

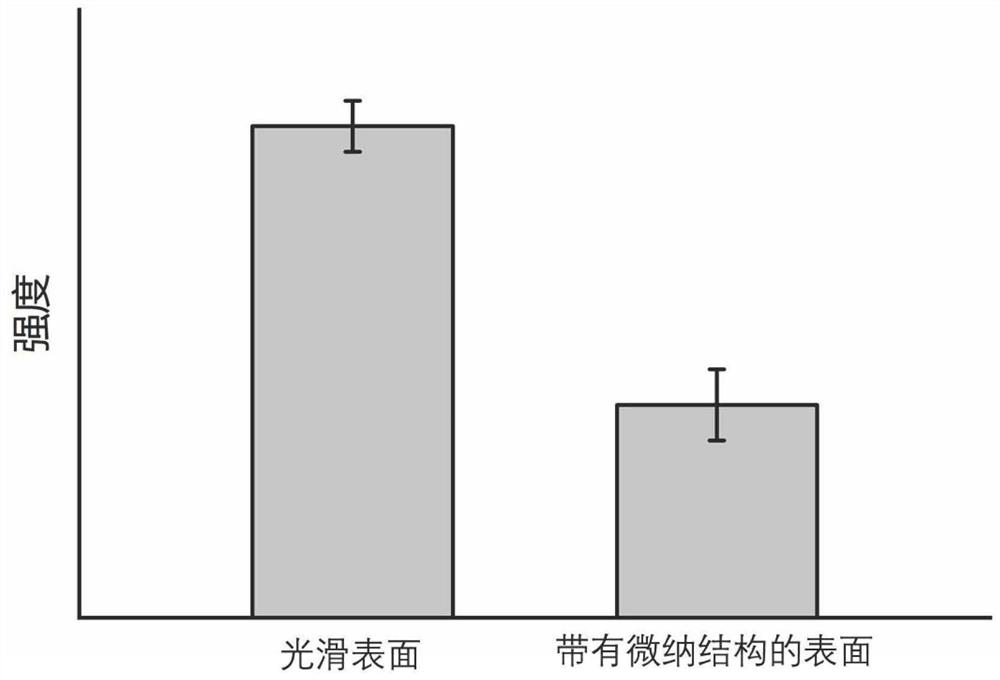

[0021] Fix a nickel-titanium wire with a diameter of 0.4mm and a length of 1m, and apply force at both ends to straighten the nickel-titanium wire so that the laser spot is irradiated on the surface of the nickel-titanium wire. The laser processing technology is: pulse energy 800μJ, laser scanning speed 1mm / s, spot size 100μm, laser scanning line spacing 80μm. The laser spot scans once along the axial direction of the nickel-titanium wire, the nickel-titanium wire rotates 15° around the axis, the laser spot scans again along the axial direction, and so on, scanning the entire surface of the nickel-titanium wire. The processed surface micro-nano structure such as figure 1 Shown, where a, b are the first-order and second-or...

Embodiment 2

[0046] In this example, a micro-nano structure with anti-fibroblast adhesion, anti-protein adhesion and anti-infection functions was prepared on the surface of nickel-titanium wire by two pulse laser processing, the specific steps are as follows:

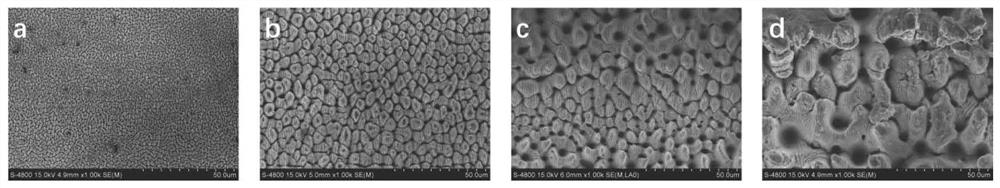

[0047] Fix a nickel-titanium wire with a diameter of 0.6mm and a length of 0.5m, and apply force at both ends to straighten the nickel-titanium wire so that the laser spot is irradiated on the surface of the nickel-titanium wire. The laser processing technology is: pulse energy 600μJ, laser scanning speed 2mm / s, spot size 80μm, laser scanning line spacing 50μm. The laser spot scans once along the axial direction of the nickel-titanium wire, the nickel-titanium wire rotates 30° around the axis, the laser spot scans again along the axial direction, and so on, scanning the entire surface of the nickel-titanium wire. The processed structure is a primary structure, which is micron protrusions with a size of about 6 μm and a height of abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com