Method for preparing carbon quantum dots from olive plant essential oil extraction residues

A technology of plant essential oils and carbon quantum dots, applied in chemical instruments and methods, nano-carbon, luminescent materials, etc., can solve the problems of low yield of essential oils of olive plants, achieve high-value utilization, solve waste problems, and quantum The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Prior to this embodiment, the reaction system was investigated in acid solubility Myrrh essential oil extraction residue, the results obtained, acid solubility Myrrh essential oil extraction residue was 16.38%.

[0046] . S1 Myrrh essential oil extraction residue was collected, dried and pulverized to obtain a powder residue myrrh;

[0047] . S2 weigh 1g step S1 myrrh powder residue was added 30mL of water and 4mL of acetic acid was added, stirred for 1h at room temperature to obtain a mixture;

[0048] S3. The resulting mixture was placed in step S2 apparatus 170 ℃ hot water in the hydrothermal reaction, the reaction time of 8h, the resulting product was cooled, filtered, the filtrate was collected and dried using a molecular weight cut-off dialysis tubing 1000Da in distilled water dialyzed 18h, the solution after the dialysis was centrifuged at 8000rpm 15min, the resulting supernatant is the carbon quantum dot solution.

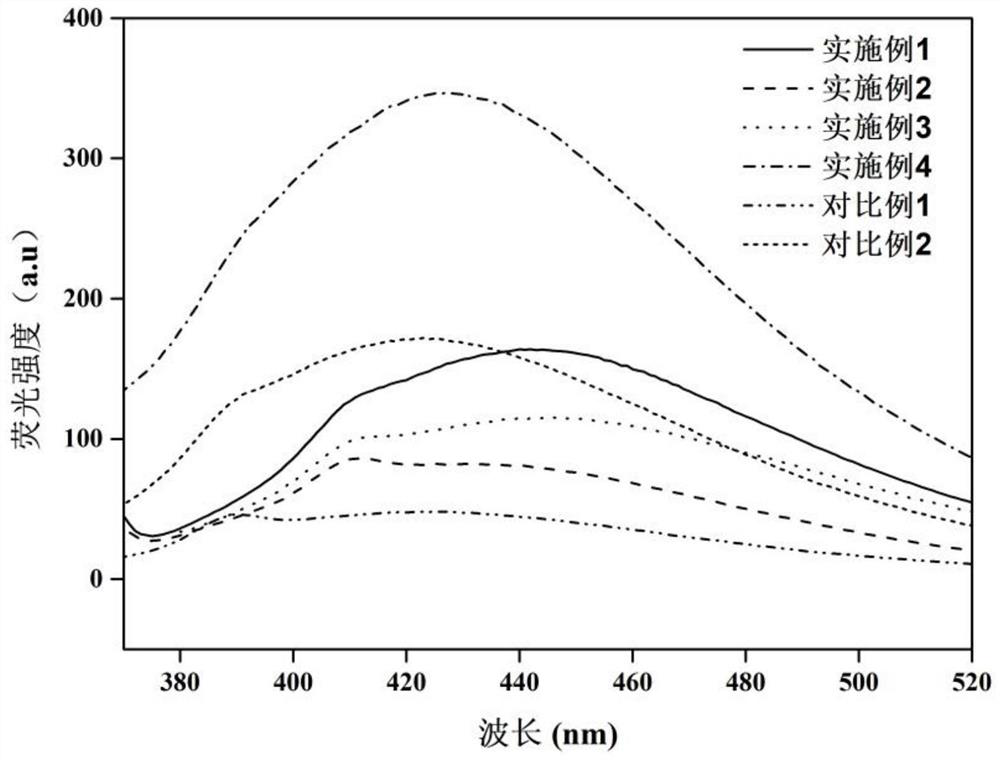

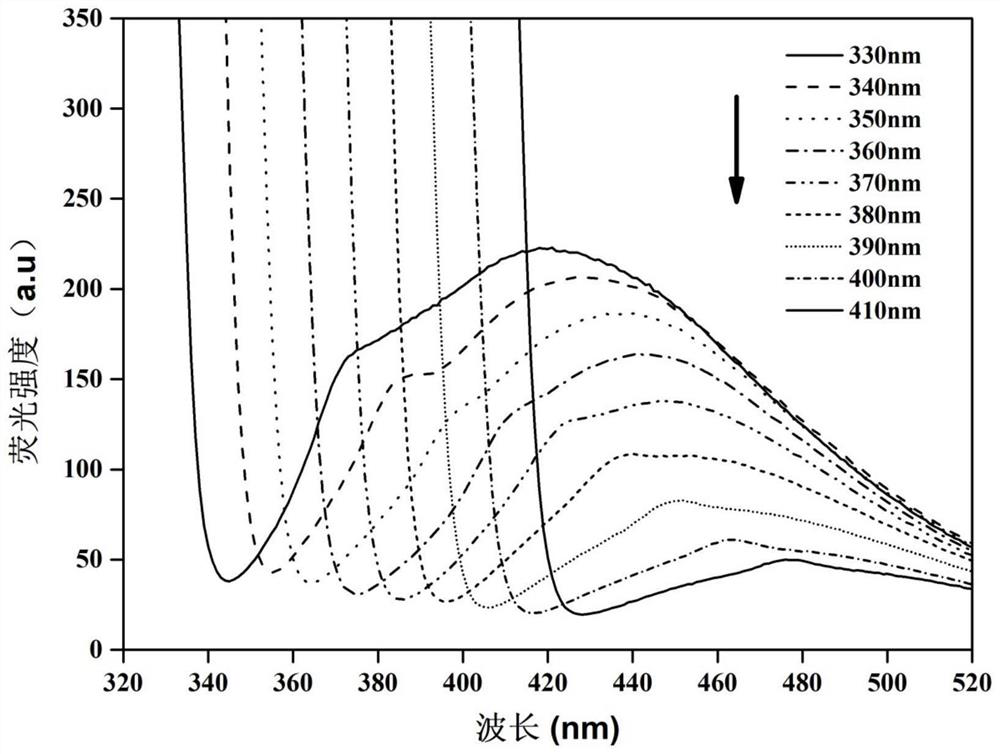

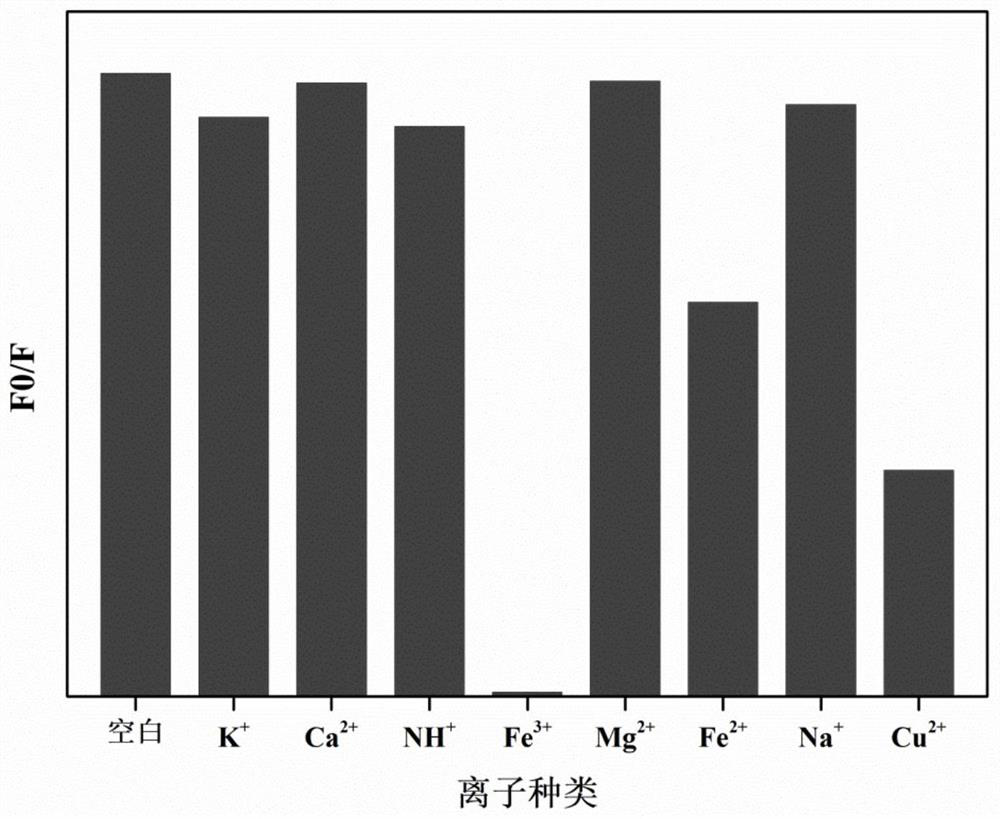

[0049] Quantum dots quantum yield of carbon obtain...

Embodiment 2

[0051] Prior to this embodiment, it investigated the solubility of the acid residue frankincense extract the reaction system, the results obtained, frankincense acid on the solubility of the extracted residue of 0.64%.

[0052] . S1 frankincense extract residue was collected, dried and pulverized to obtain a powder residue frankincense;

[0053] . S2 Step S1 Weigh 0.5g of powder was added to the residue mastic 15mL of water and 2mL acid was added, stirred for 1h at room temperature to obtain a mixture;

[0054] S3. The resulting mixture was placed in step S2 apparatus 200 ℃ hot water in the hydrothermal reaction, the reaction time of 8h, the resulting product was cooled, filtered, the filtrate was collected and dried using a molecular weight cut-off dialysis tubing 1000Da in distilled water dialyzed 18h, the solution after the dialysis was centrifuged at 10000rpm 10min, the resulting supernatant is the carbon quantum dot solution.

[0055] Quantum dots quantum yield of carbon obta...

Embodiment 3

[0057] Prior to this embodiment, the solubility of the reaction system was investigated in the extraction residue of ethylenediamine myrrh oil, results obtained, ethylenediamine solubility Myrrh essential oil extraction residue was 24.48%.

[0058] . S1 Myrrh essential oil extraction residue was collected, dried and pulverized to obtain a powder residue myrrh;

[0059] . S2 Step S1 Weigh 0.5g of residue myrrh powder into 20mL of water and 1mL of ethylenediamine was added, stirred for 2h at room temperature to obtain a mixture;

[0060] S3. The resulting mixture was placed in step S2 apparatus 200 ℃ hot water in the hydrothermal reaction, 9H reaction time, the resulting product was cooled, filtered, the filtrate was collected and dried using a molecular weight cut-off dialysis tubing 1000Da in distilled water dialyzed 36h, the solution after the dialysis was centrifuged at 10000rpm 10min, the resulting supernatant is the carbon quantum dot solution.

[0061] Quantum dots quantum yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com