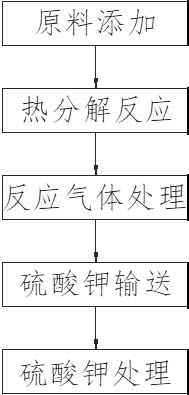

Potassium sulfate co-production compound fertilizer production device and key structure and technological process thereof

A production device and a technology for potassium sulfate are applied in the field of potassium sulfate co-production compound fertilizer production device, potassium sulfate co-production compound fertilizer production device and technological process, which can solve the problem of difficult conveying, unloading and subsequent treatment, low production capacity of potassium sulfate, Reduce the production capacity of hydrochloric acid and other problems to ensure the quality of production, convenient feeding, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0054] The following is a co-production of potassium sulfate fertilizer production apparatus of the specific embodiments.

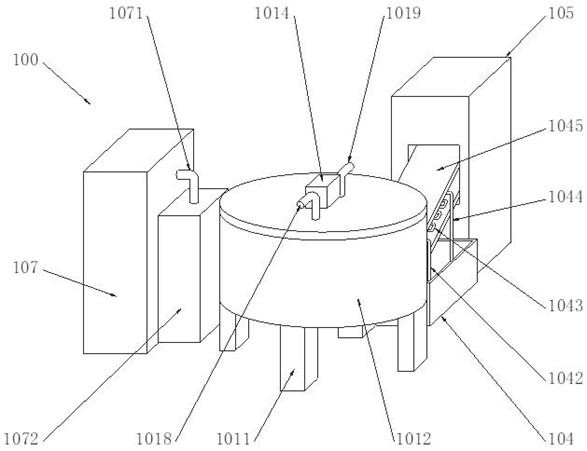

[0055] Refer Figures 1 to 11 , Co-production of potassium sulfate fertilizer production apparatus 100 comprising: an outer housing 101, inner housing 102, trough 103, the water tank 104, housing 105, diaphragm 106, and 107 washing tank.

[0056] Refer Figure 1 to 8 As a specific embodiment, wherein 101 is fixedly connected to the side wall 102, trough 103 and the outer housing inside the inner housing 101 through the fixed outer housing, the outer wall 102 and the inner end of the trough housing 103 is fixedly connected with a bottom of the corresponding trough 103 the water tank 104, the housing 105 is a side trough 103, the bottom of the housing 105 is fixedly connected with the water tank 104, the interior of the housing 105 is fixedly connected to the separator 106, washing vessel 107 is located in a side of the outer housing 101, inner housing 102 may be...

specific Embodiment approach 2

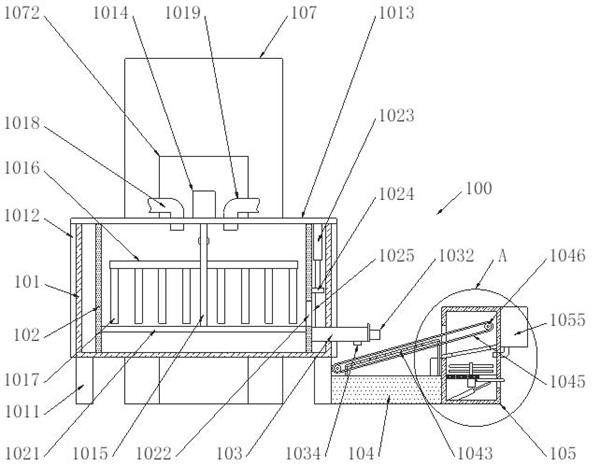

[0066] DETAILED DESCRIPTION A The following is a fertilizer production apparatus Potassium Sulfate response of the structure, the structure of the reaction may be carried out either singly or as a key structure of a co-production of potassium sulfate fertilizer production apparatus of the specific embodiment disclosed a .

[0067] One kind of a reaction structure cogeneration potassium fertilizer production apparatus, comprising: a side wall 101 of the housing 101, within the housing 102, trough 103, 102 is fixedly connected to the inner shell 101 inside the outer housing, the outer housing 103 and the trough through a fixed, outer wall 102 and the inner end of the trough housing 103 is fixedly connected to the top of the outer housing 101 and inner housing 102 are fixedly connected with the top plate 1013, a bottom surface of the top plate 1013 is attached to the hydraulic cylinder 1023 is fixed, the bottom end of the hydraulic cylinder via the connecting plate 1023 102 fixedly c...

specific Embodiment approach 3

[0068] The following specific embodiments of a delivery structure Potassium Sulfate fertilizer production apparatus, the conveyor structure may be implemented alone, or as a key structure of a co-production of potassium sulfate fertilizer production apparatus of the specific embodiment disclosed a .

[0069] Potassium Sulfate transport one kind of compound fertilizer production unit structure, comprising: a water tank 104, the belt 1045 is provided between the water tank 104 and the trough 103, the belt 1045 is inclined distribution, one end of the belt extends through the housing 105 1045 internally, 1045 by the conveying belt drive roller 1046 is connected, wherein a transport roller 1046 is fixedly connected to the output terminal of the drive motor 1047, drive motor 1047 and the outer wall of the housing 105 is fixedly connected to the water tank 104 is located between the legs 105 and the housing 1011, the water tank 104 is fixedly connected to the submersible pump 1041, 1041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com