Modified silicon dioxide filler and preparation method thereof

A silica and modification technology, applied in the field of chemical engineering, can solve the problem of low surface grafting amount, and achieve the effects of increasing the surface grafting amount, avoiding the reduction of dispersibility, and reducing the preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

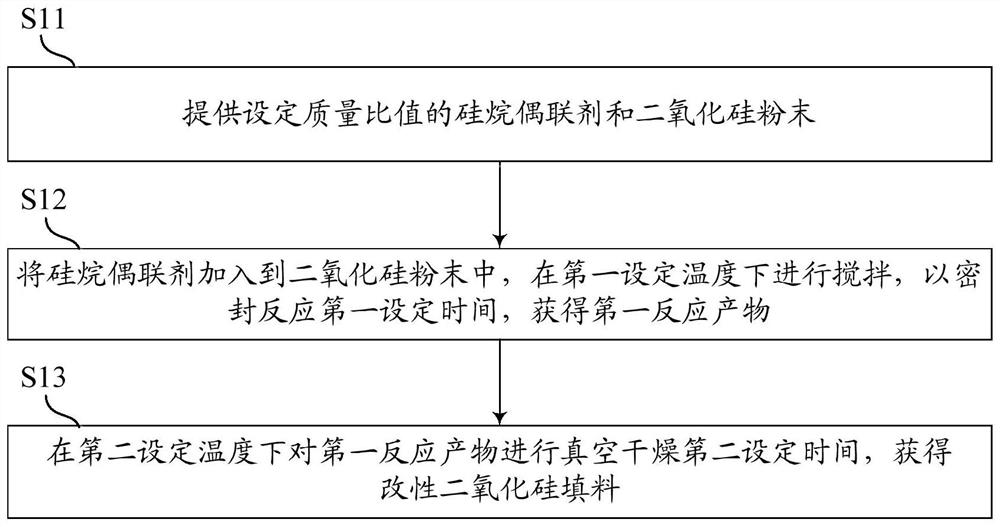

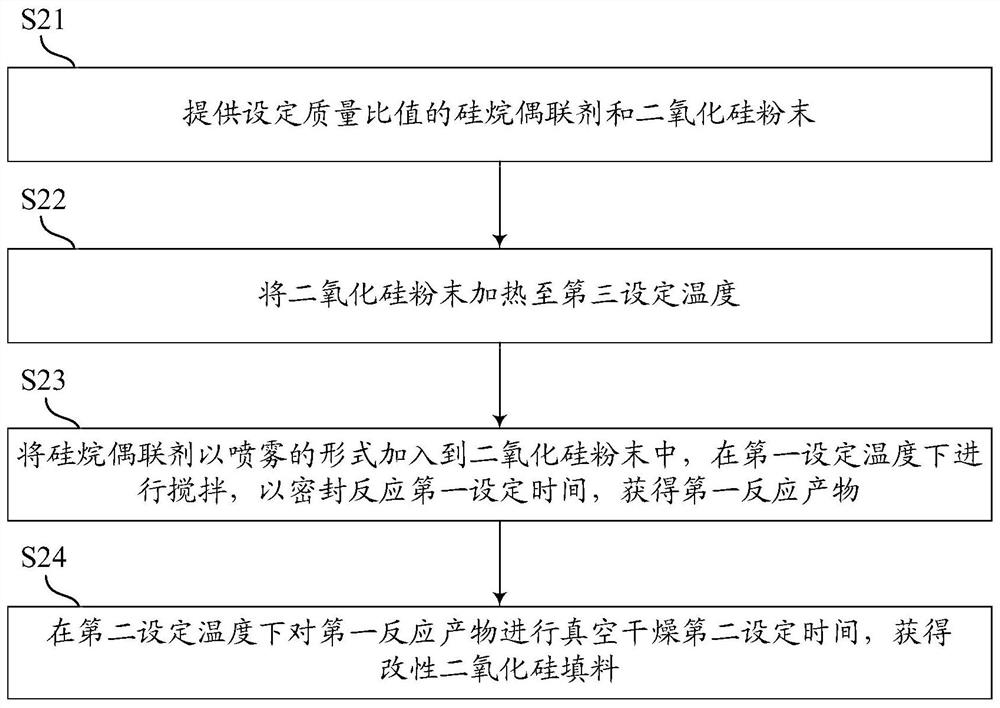

[0028] see figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the preparation method of the modified silica filler of the present application. In this embodiment, the preparation method includes:

[0029] S11: Provide a silane coupling agent and silicon dioxide powder with a set mass ratio.

[0030] Understandably, silica fillers have been widely used in electronic packaging materials such as underfill adhesives, epoxy molding compounds, and insulating adhesive films due to their low thermal expansion coefficient, good thermal and chemical stability, and the like. Among them, the thermal expansion coefficient of the resin material added with silica filler decreases with the increase of silica filling amount, but the silica filler without surface modification is easy to be caused by the cohesion between fillers under the condition of high filling. Poor compatibility between the filler and the resin leads to an increase in the viscosity of the system ...

Embodiment 1

[0070] Put 0.5-5g silica powder, 0.1-5% silane coupling agent and 20-50ml organic dispersant in sequence in 100ml hydrothermal tank with Teflon lining The reaction kettle is sealed for 0.5-24 hours of reaction at 120-180° C. with a stirring speed of 200-500 rpm.

[0071] Wherein, the silica average particle size range is 0.2-5 microns; the silane coupling agent can be 3-aminopropyltrimethoxysilane, 3-aminopropyltriethoxysilane, bis(3-trimethoxy silylpropyl)amine, N-cyclohexyl-γ-aminopropyltrimethoxysilane, γ-glycidyloxypropyltrimethoxysilane (KBM-403), 3-(2,3-cyclo Oxypropoxy)propylmethyldimethoxysilane, γ-glycidyl etheroxypropyltriethoxysilane or a mixture of one or more of silane coupling agents with other functional groups; the organic dispersant It can be one or a mixture of methanol, ethanol, isopropanol, and propanol.

[0072] Further, the product of the hydrothermal reaction is separated by high-speed centrifugation at 6000-8000 rpm, and the centrifuged product is vac...

Embodiment 2

[0074] With the silicon dioxide powder of 0.5g average particle diameter 300 nanometers, the mass percent with silicon dioxide powder is the KBM-403 (gamma-glycidyl ether oxypropyltrimethoxysilane) silane coupling agent, 200 milliliters Add ethanol to the three-necked flask of 500 ml, through an oil bath or a pressurized water bath, that is, place the sealed three-necked flask in hot water or hot oil, so that the KBM-403 inside the three-necked flask and the The silicon dioxide powder is heated so that it reaches 150°C, and the silicon dioxide powder is reacted with KBM-403 silane coupling agent for 24 hours at a stirring speed of 400 rpm and cold water reflux at 18°C; The product is separated by high-speed centrifugation at 6000 rpm; the centrifuged product is vacuum-dried at 150° C. for 5 hours to obtain the final surface-modified silica filler, wherein the TGA (thermogravimetry) of the modified silica filler Analysis) The weight loss rate was 0.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com