Modified alcohol detergent and preparation method thereof

A modification and alcohol cleaning technology, which is applied in the field of cleaning agents, can solve problems affecting the performance of parts, easy to be stained with oil, and inconvenience to users, so as to improve performance, anti-fouling performance, high temperature resistance and anti-corrosion. The effect of dirt performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

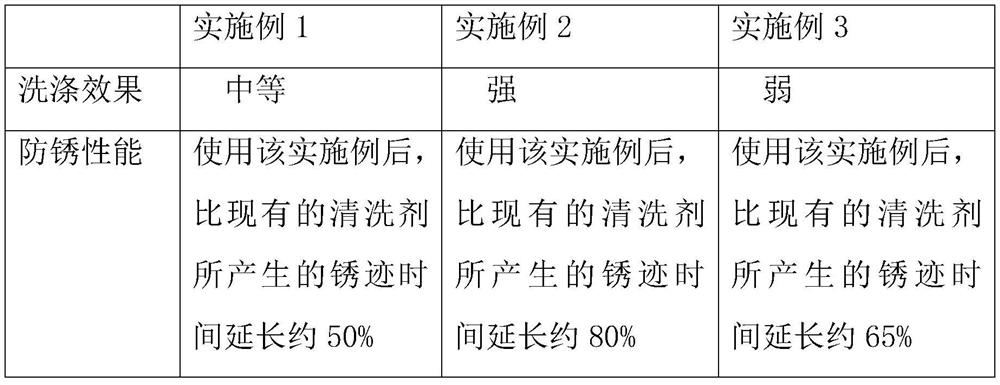

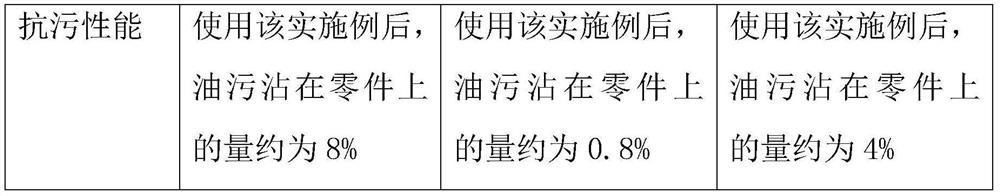

Embodiment 1

[0031] A modified alcohol cleaning agent provided by the invention comprises raw materials and auxiliary materials, and the raw materials (by weight) include: 8g of water, 2g of modified methanol, 2g of alkane, 1g of cycloalkane, 2g of aromatic hydrocarbon, tetrachloroethylene 1g, normal hexane 2g, freon 1g, methyl ethyl ketone 1g, described auxiliary material (by weight) comprises: cocoamide diethanolamine 4g, polyepoxysuccinic acid 6g, antifouling agent 4g, antirust oil 8g, stabilizer 2g, Nonionic surfactant 2g;

[0032] Furthermore, cocoamide diethanolamine is prepared by the reaction of coconut oleic acid and diethanolamine. It is an amber viscous liquid with strong foaming power, penetrating power, detergency, rust resistance and good dispersibility, etc. ;

[0033] Polyepoxysuccinic acid is a nitrogen-free, non-phosphorus organic compound with dual functions of scale and corrosion inhibition.

[0034] Further, the antifouling agent is one or more mixtures of fluorine-m...

Embodiment 2

[0047] A modified alcohol cleaning agent provided by the invention comprises raw materials and auxiliary materials, and the raw materials (by weight) include: 9 g of water, 5 g of modified methanol, 3 g of alkane, 1.5 g of cycloalkane, 2.5 g of aromatic hydrocarbon, Vinyl chloride 2g, normal hexane 3g, freon 2g, methyl ethyl ketone 1.5g, described auxiliary material (by weight) comprises: cocoamide diethanolamine 5g, polyepoxysuccinic acid 7g, antifouling agent 6g, antirust oil 9g, stabilizer Agent 4g, nonionic surfactant 3g.

[0048]Further, the antifouling agent is one or more mixtures of fluorine-modified siloxane and fluorine-based polyether-modified polysiloxane.

[0049] Further, the antirust oil is composed of a corrosion inhibitor and a base oil, and the corrosion inhibitor is one or more mixtures of lead naphthenate, zinc naphthenate, and sodium petroleum sulfonate.

[0050] Further, the stabilizer is one or more mixtures of phosphite, antioxidant and hydrotalcite. ...

Embodiment 3

[0060] A modified alcohol cleaning agent provided by the invention comprises raw materials and auxiliary materials. The raw materials (by weight) include: water 10g, modified methanol 8g, alkane 4g, cycloalkane 2g, aromatic hydrocarbon 3g, tetrachloroethylene 3g, normal hexane 4g, freon 3g, methyl ethyl ketone 2g, described auxiliary material (by weight) comprises: cocoamide diethanolamine 6g, polyepoxysuccinic acid 8g, antifouling agent 8g, antirust oil 10g, stabilizer 6g, Nonionic surfactant 4g.

[0061] Further, the antifouling agent is one or more mixtures of fluorine-modified siloxane and fluorine-based polyether-modified polysiloxane.

[0062] Further, the antirust oil is composed of a corrosion inhibitor and a base oil, and the corrosion inhibitor is one or more mixtures of lead naphthenate, zinc naphthenate, and sodium petroleum sulfonate.

[0063] Further, the stabilizer is one or more mixtures of phosphite, antioxidant and hydrotalcite.

[0064] Further, the nonion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com