A vapor phase epitaxy system and its maintenance operation method

A technology of vapor phase epitaxy system and inlet flange, which is applied in the field of vapor phase epitaxy system and its maintenance operation, can solve the problems of inconvenient maintenance and low utilization rate of large-sized reaction chambers, and achieve improved equipment utilization rate and yield, low temperature The effect of less dead zone and increased number of furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

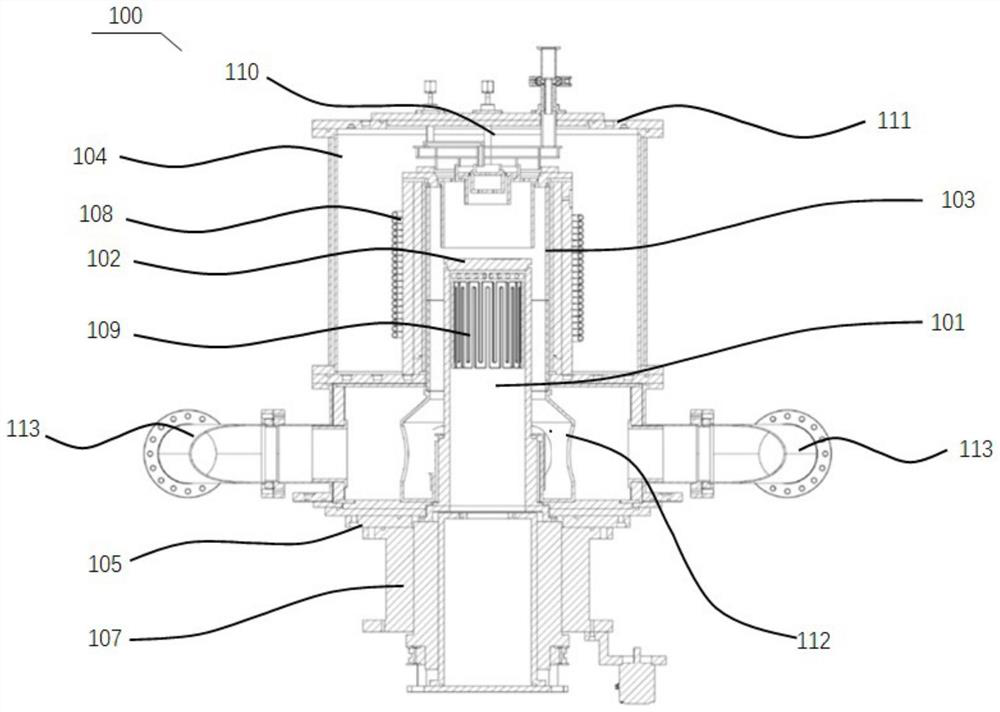

[0050] FIG. 1 shows an exemplary cross-sectional structure diagram of the vapor phase epitaxy system 100 provided in this embodiment. the gas phase

[0051] The disk carrier support device 101 passes through the cover body 105, and the cover body 105 is connected to the disk carrier support device 101,

[0053] As an example, the materials constituting the inner chamber 103 include but are not limited to quartz, silicon carbide, aluminum oxide, nitride

[0054] As an example, the material constituting the outer chamber 104 includes, but is not limited to, metallic materials, such as stainless steel.

[0055] In an example, the outer chamber 104 is provided with a water cooling pipe, and the water cooling pipe can be arranged in the outer chamber

[0056] In an example, the vapor phase epitaxy system 100 further includes an exhaust device that includes an exhaust chamber

[0057] As an example, the outer chamber 104 is provided with an external heater 108, the external heater 108 i...

Embodiment 2

[0060] The vapor phase epitaxy system described in this embodiment has a larger structure than the vapor phase epitaxy system 100 described in the first embodiment.

[0061] Specifically, please continue to refer to FIG. 1 . As shown in FIG. 1, the outer chamber 104 is provided with an external heater 108, the

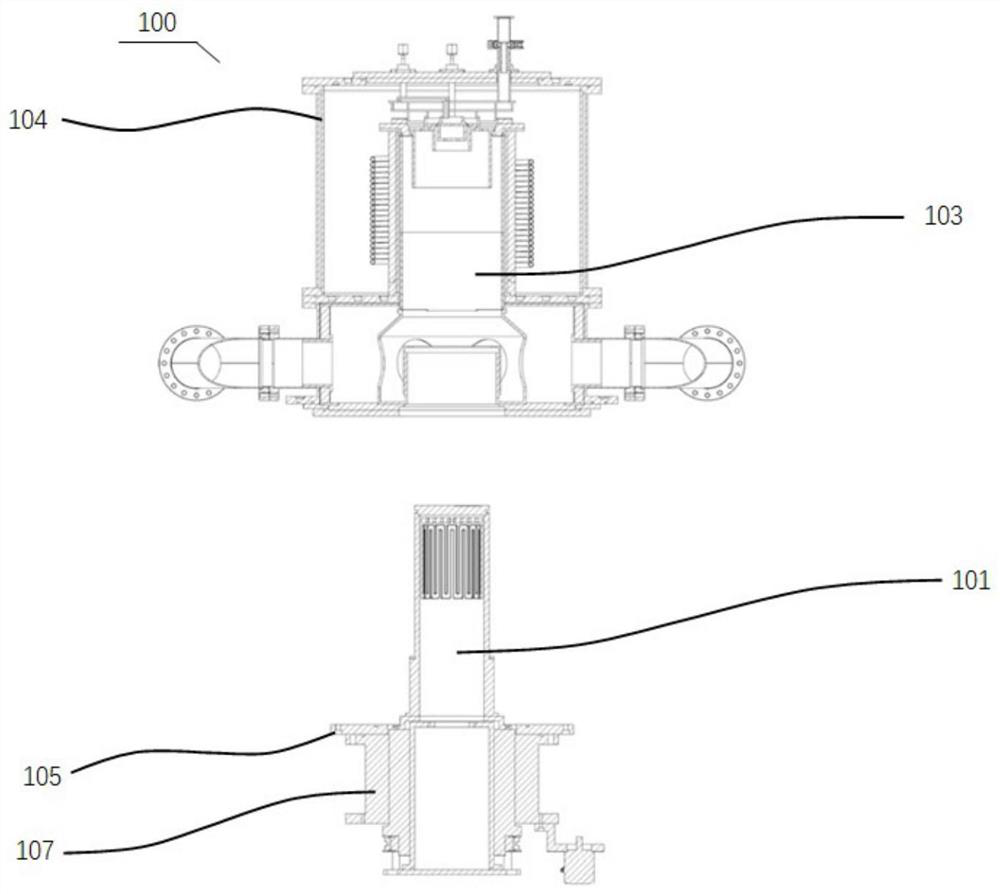

[0068] After the epitaxial growth, as shown in FIG. 2, the cover body 105 is opened, the cover body 105 together with the carrier plate 102 and the

[0069] Similarly, the replacement of the carrier disk 102 can be completed according to the above-mentioned operations, and the carrier disk to be cleaned can be processed in a vapor phase epitaxy system.

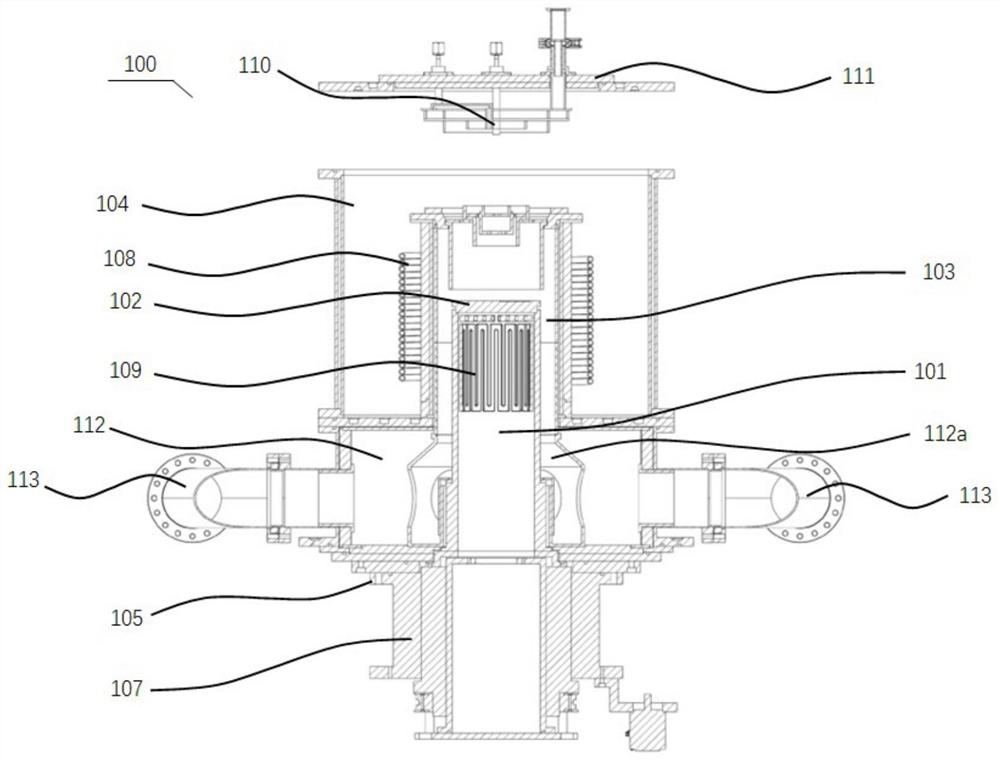

[0071] As shown in FIG. 3, in the vapor phase epitaxy process, the semiconductor thin film that should be deposited on the substrate will be attached to the top of the cavity

[0074] To sum up, the present invention provides a vapor phase epitaxy system and an operation and maintenance method thereof. Vapor phase epitaxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com