Tungsten disulfide/molybdenum disulfide/ graphene composite material with layered structure and preparation method and application thereof

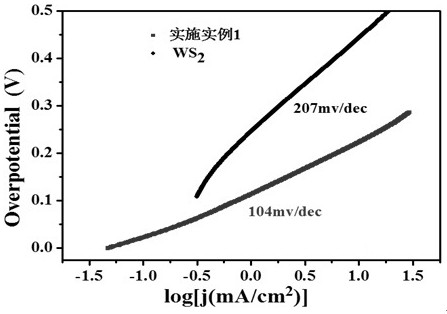

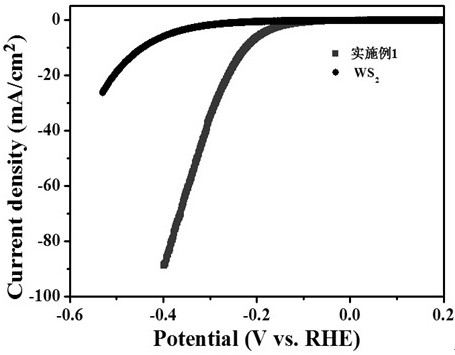

A molybdenum disulfide, tungsten disulfide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of unsatisfactory catalytic performance, high cost, and cumbersome, and achieve excellent hydrogen evolution catalysis. Performance, high cost, effect of high active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

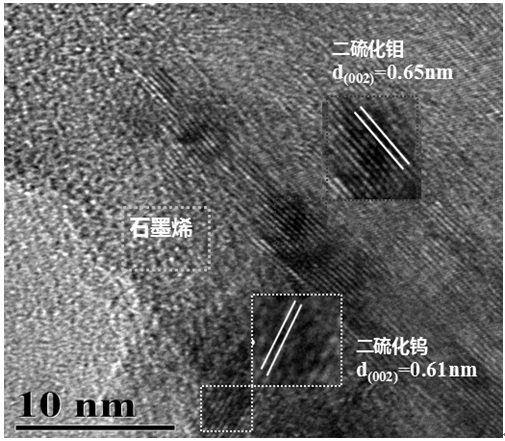

[0095] The present invention also provides a preparation method of tungsten disulfide / molybdenum disulfide / graphene composite material, comprising the following steps:

[0096] 1) After dispersing the molybdenum disulfide powder, the first surfactant and water, a dispersion liquid is obtained, and then centrifuged and ground to obtain molybdenum disulfide micro-nano sheets;

[0097]Dispersing and mixing the expanded graphite, the second surfactant and water to obtain a dispersion, and then centrifuging and grinding to obtain graphene micro-nano sheets;

[0098] After mixing tungsten hexachloride, ammonium tungstate and water, a mixed solution A is obtained;

[0099] 2) After redispersing the molybdenum disulfide micro-nanosheets, graphene micro-nanosheets, sulfur source, third surfactant and water obtained in the above steps, the mixed solution B is obtained;

[0100] 3) Mix the mixed solution B obtained in the above steps with the mixed solution A again, adjust the pH value,...

Embodiment 1

[0141] Add a certain amount of molybdenum disulfide powder and sodium lauryl sulfate into deionized water. The mass ratio of molybdenum disulfide powder and deionized water is 1:100 to form a mixed solution. After ultrasonic dispersion for 120 minutes, a dispersion solution is formed; then First, centrifuge at a low speed of 500rmp / min for 5min, take the upper layer solution, and then centrifuge at a high speed at a rate of 5000r / min for 10min, remove the lower layer solution and wash; then dry and grind in a vacuum drying room at 60°C overnight to form molybdenum disulfide Micro-nanosheets.

[0142] Add a certain amount of expanded graphite and octadecyltrimethylammonium chloride into deionized water, the mass ratio of expanded graphite to deionized water is 1:100 to form a mixed solution, which is dispersed by ultrasonic for 120 minutes to form a dispersion; then First centrifuge at a low speed of 500rmp / min for 5min, take the upper layer solution, and then centrifuge at a h...

Embodiment 2

[0151] Add a certain amount of molybdenum disulfide powder and sodium lauryl sulfate into deionized water. The mass ratio of molybdenum disulfide powder and deionized water is 1:100 to form a mixed solution. After ultrasonic dispersion for 120 minutes, a dispersion solution is formed; then First, centrifuge at a low speed of 500rmp / min for 5min, take the upper layer solution, and then centrifuge at a high speed at a rate of 5000r / min for 10min, remove the lower layer solution and wash; then dry and grind in a vacuum drying room at 60°C overnight to form molybdenum disulfide Micro-nanosheets.

[0152]Add a certain amount of expanded graphite and octadecyltrimethylammonium chloride into deionized water, the mass ratio of expanded graphite to deionized water is 1:100 to form a mixed solution, which is dispersed by ultrasonic for 120 minutes to form a dispersion; then First centrifuge at a low speed of 500rmp / min for 5min, take the upper layer solution, and then centrifuge at a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com