Tear-resistant mixed master batch suitable for mixing by twin-screw extruder

A twin-screw extruder, anti-tearing technology, applied in the field of twin-screw extruder mixing and mixing master batches, can solve the problems of unresolved, dust pollution, uneven dispersion, etc., and achieve excellent tear resistance, high Liquidity, the effect of increased liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

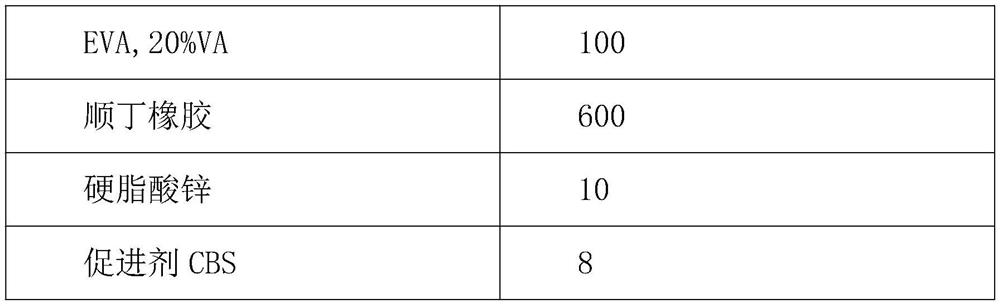

[0040] A masterbatch contains the following ingredients (unit, part):

[0041]

[0042]

[0043] After the above components are uniformly mixed with an internal mixer, the masterbatch A is obtained after granulation with a single-screw extruder.

[0044] B masterbatch contains the following ingredients (unit, part):

[0045] EVA, 40%VA 100 sulfur 20

[0046] After the above components are uniformly mixed with an internal mixer, the masterbatch B is obtained after granulation with a single-screw extruder.

[0047] Mix masterbatch A and masterbatch B at a ratio of 5:1 to obtain a mixed masterbatch.

[0048] Mix the mixed masterbatch in a twin-screw extruder, the temperature of the extruder is 80°C, and the rotation speed is 60rpm to obtain a mixed rubber, which is used to evaluate the uniformity according to the uniformity evaluation method.

[0049] Put the mixed rubber into a standard sample mold, vulcanize at 160°C for 30 minutes to obtain a test ...

Embodiment 2

[0099] A masterbatch contains the following ingredients (unit, part):

[0100] EVA, 26%VA 100 SBR 600 Zinc stearate 80 Accelerator CZ 12 SEBS 100

[0101] After the above components are uniformly mixed with an internal mixer, the masterbatch A is obtained after granulation with a single-screw extruder.

[0102] B masterbatch contains the following ingredients (unit, part):

[0103] EVA, 35%VA 100 sulfur 30

[0104] After the above components are uniformly mixed with an internal mixer, the masterbatch B is obtained after granulation with a single-screw extruder.

[0105] Mix masterbatch A and masterbatch B at a ratio of 5:1 to obtain a mixed masterbatch.

[0106] Mix the mixed masterbatch in a twin-screw extruder, the temperature of the extruder is 80°C, and the rotation speed is 60rpm to obtain a mixed rubber, which is used to evaluate the uniformity according to the uniformity evaluation method.

[0107] Put the ...

Embodiment 3

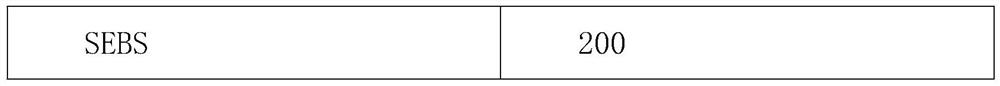

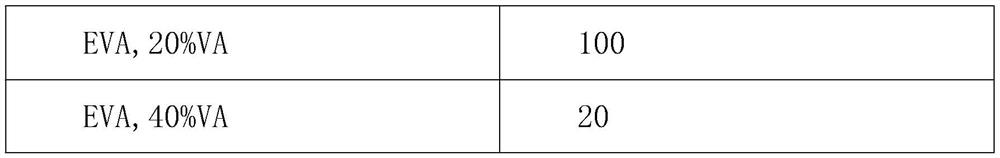

[0109] A masterbatch contains the following ingredients (unit, part):

[0110]

[0111]

[0112] After the above components are uniformly mixed with an internal mixer, the masterbatch A is obtained after granulation with a single-screw extruder.

[0113] B masterbatch contains the following ingredients (unit, part):

[0114] EVA, 40%VA 100 sulfur 30 Antiaging agent 4010NA 25

[0115] After the above components are uniformly mixed with an internal mixer, the masterbatch B is obtained after granulation with a single-screw extruder.

[0116] Mix masterbatch A and masterbatch B at a ratio of 5:1 to obtain a mixed masterbatch.

[0117] Mix the mixed masterbatch in a twin-screw extruder, the temperature of the extruder is 80°C, and the rotation speed is 60rpm to obtain a mixed rubber, which is used to evaluate the uniformity according to the uniformity evaluation method.

[0118] Put the mixed rubber into a standard sample mold, vulcanize at 180°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com