Polyelectrolyte compound hydrogel fiber and preparation method thereof

A hydrogel fiber, polyelectrolyte technology, applied in the direction of animal fibers, synthetic fibers, conjugated synthetic polymer rayon, etc., can solve problems such as poor mechanical properties, and achieve good mechanical strength and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

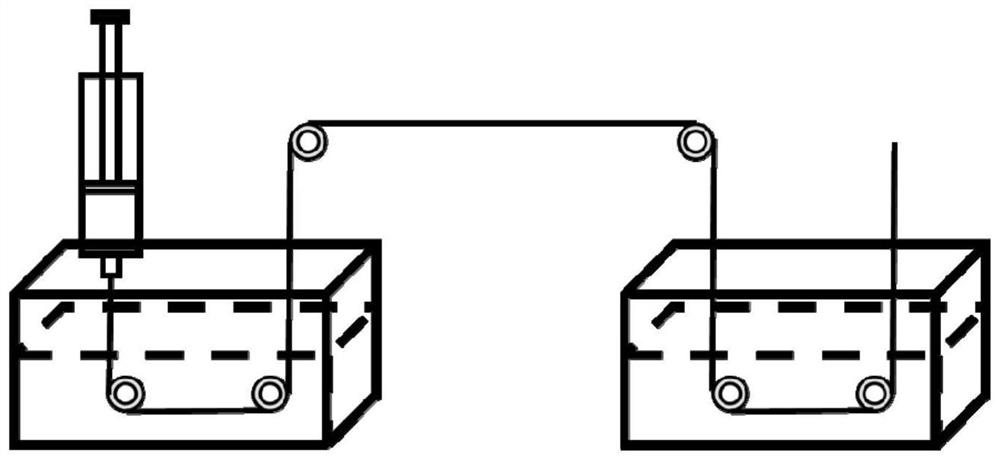

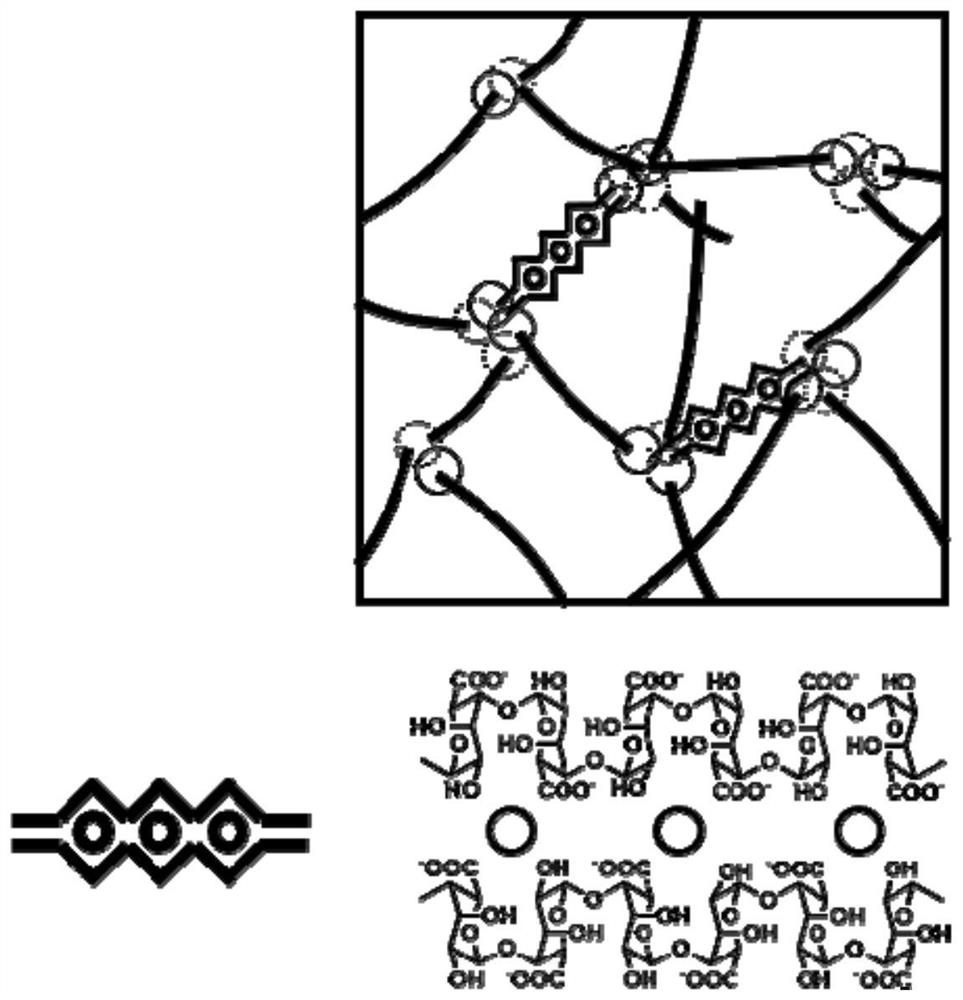

[0041] A preparation method of a polyelectrolyte composite hydrogel fiber, the specific steps are as follows:

[0042] (1) Preparation of raw materials:

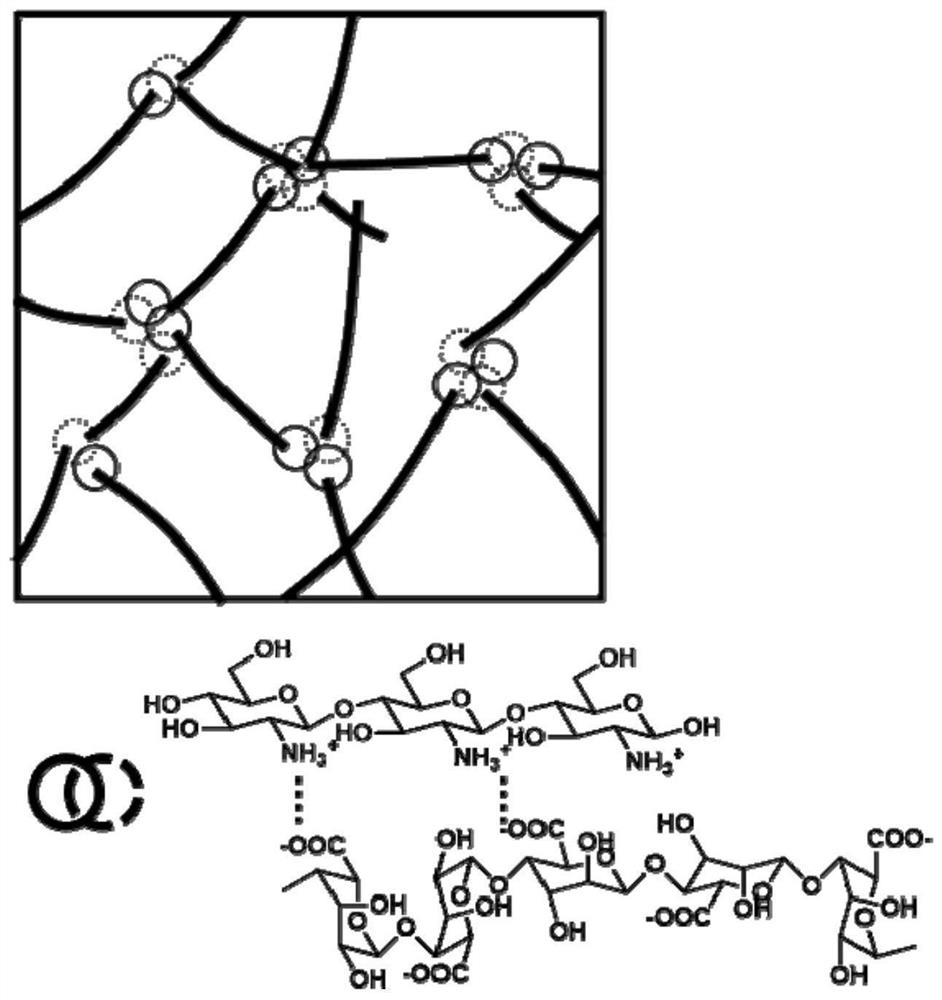

[0043] Polyelectrolyte solution X: dissolving chitosan in acetic acid solution, adjusting its pH value to 3.5, and centrifuging and defoaming to obtain polyelectrolyte solution X with a mass fraction of polyelectrolyte of 1.5wt.%.

[0044] Polyelectrolyte solution Y: Sodium alginate was dissolved in deionized water, and then centrifuged and defoamed to obtain polyelectrolyte solution Y with a mass fraction of polyelectrolyte of 1.5wt.%.

[0045] Solution containing metal ion C: CaCl 2 Dissolve in deionized water to obtain a solution containing metal ion C with a concentration of 1 mg / mL;

[0046] (2) First use polyelectrolyte solution X as the spinning solution to carry out wet spinning, after compounding with polyelectrolyte solution Y for 24 hours in the coagulation bath, and then washing for 20 seconds, polyelectrolyte ...

Embodiment A2

[0054] A preparation method of a polyelectrolyte composite hydrogel fiber, the specific steps are as follows:

[0055] (1) Preparation of raw materials:

[0056] Polyelectrolyte solution X: polyallylamine was dissolved in deionized water, and its pH value was adjusted to 3.5, and then centrifuged and defoamed to obtain a polyelectrolyte solution X with a mass fraction of polyelectrolyte of 0.8wt.%.

[0057] Polyelectrolyte solution Y: Dissolve N,N-dicarboxymethylpolyallylamine in deionized water, adjust its pH value to 3.5, and then centrifuge and defoam to obtain a polyelectrolyte with a mass fraction of polyelectrolyte of 1wt.%. Solution Y;

[0058] A solution containing metal ions C: FeCl 3 Dissolve in deionized water to obtain a solution containing metal ion C with a concentration of 1.5 mg / mL;

[0059] (2) First use polyelectrolyte solution X as the spinning solution to carry out wet spinning, and after compounding with polyelectrolyte solution Y for 18 hours in the co...

Embodiment A3

[0064] A preparation method of a polyelectrolyte composite hydrogel fiber, the specific steps are as follows:

[0065] (1) Preparation of raw materials:

[0066] Polyelectrolyte solution X: Dissolve polydiallyldimethylammonium chloride in deionized water, adjust its pH value to 3, and then centrifuge and defoam to obtain a polyelectrolyte solution with a mass fraction of polyelectrolyte of 1.2wt.%. X;

[0067] Polyelectrolyte solution Y: Dissolve N,N-dicarboxymethyl branched polyethyleneimine in deionized water, adjust its pH value to 3, and then centrifuge and defoam to obtain polyelectrolyte with a mass fraction of 1.5wt.%. Polyelectrolyte solution Y;

[0068] Solution containing metal ion C: EuCl 3 Dissolve in deionized water to obtain a solution containing metal ion C with a concentration of 1 mg / mL;

[0069] (2) First use polyelectrolyte solution X as the spinning solution to carry out wet spinning, after compounding with polyelectrolyte solution Y for 12 hours in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com