Laser vibration test inspection method for detecting pasting quality of thin plaster heat insulation system

A thermal insulation and vibration testing technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, special data processing applications, etc., can solve problems such as large experience dependence, stress wave attenuation, poor detection effect, etc., to achieve detection The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

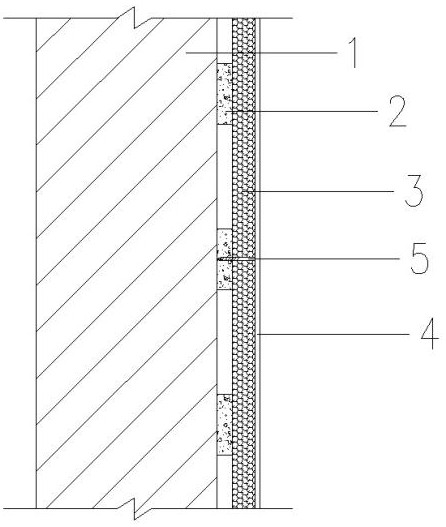

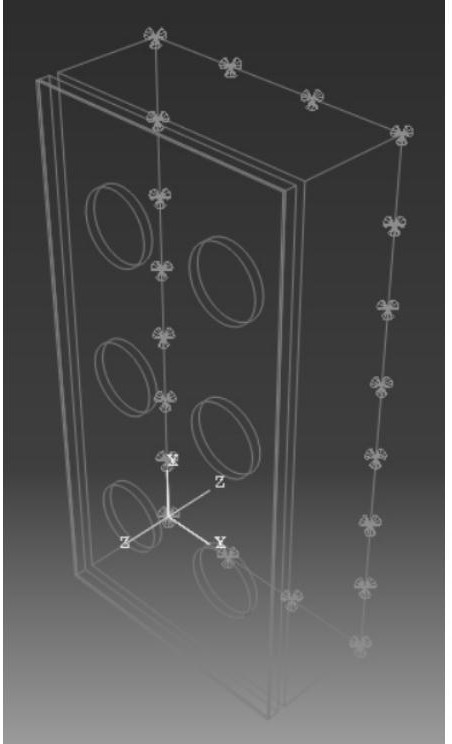

[0035] Take the EPS thin plastering system as an example. Collect the composition and pasting method of the thin plaster thermal insulation system: the EPS board thin plaster external thermal insulation system consists of an adhesive layer, EPS thermal insulation board, plastering layer and facing layer. The EPS insulation board is pasted on the base layer of the wall with an adhesive, and the glass fiber mesh is covered in the thin plastering mortar. The plastering layer is generally modified mortar, and the finishing layer can be elastic paint. The system structure is as follows: figure 1 As shown in the figure, 1 is the base wall; 2 is the adhesive; 3 is the insulation board; 4 is the anchor bolt; 5 is the thin plaster mortar.

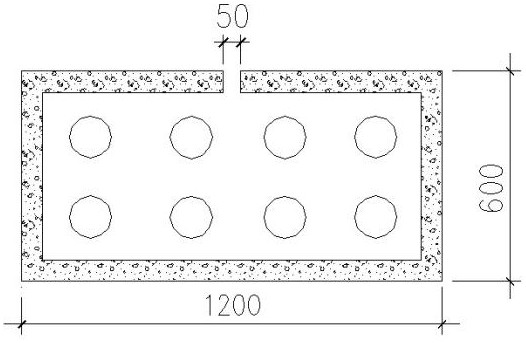

[0036] In this example, an adhesive with a width of about 60 mm and a thickness of about 10 mm is coated on the periphery of each EPS board (the standard board size is 600mm×1200mm), and then 8 pieces of adhesive with a diameter of about 120 mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com