High-flexibility graphene-based supercapacitor based on laser processing and preparation method thereof

A supercapacitor and graphene-based technology, applied in the field of capacitors, can solve the problems of difficult processing of tiny devices, inability to achieve fine processing, and rough processing, and achieve the effects of easy operation, increased area, and improved tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

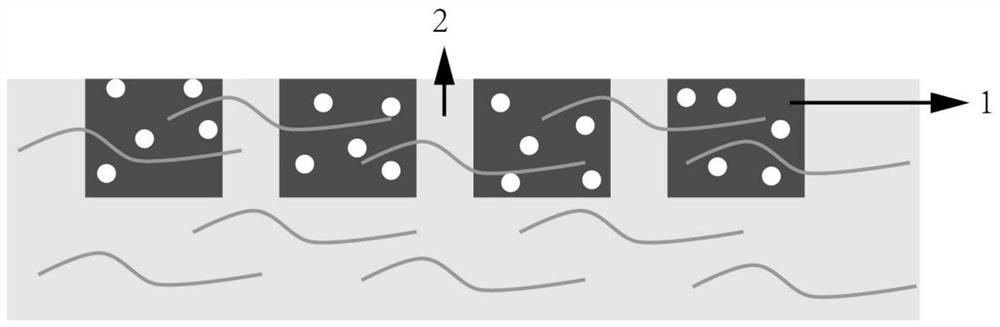

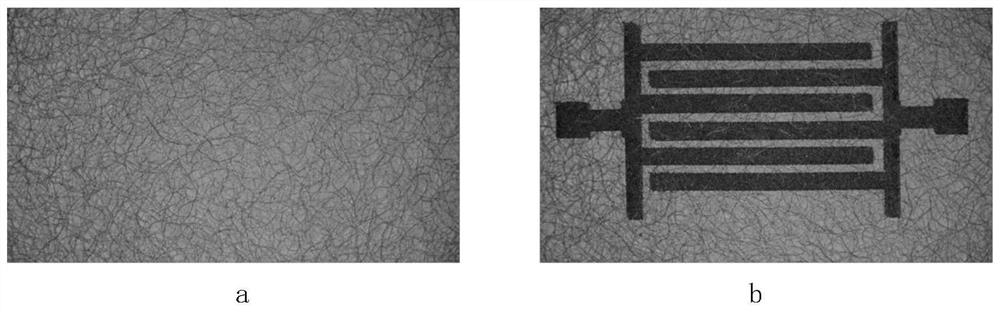

[0048] Such as figure 1 As shown, the present embodiment provides a highly flexible graphene-based supercapacitor based on laser processing, the highly flexible graphene-based supercapacitor is a planar structure, composed of graphene / fiber composite electrode 1 and graphene oxide / Composed of a fiber composite diaphragm 2; the graphene / fiber composite electrode 1 is an interdigitated region formed by laser scanning on the surface of the graphene oxide / fiber composite diaphragm 2.

[0049] The graphene / fiber composite electrode 1 has a porous structure, which can increase the specific surface area of the material, is conducive to full contact with the electrolyte, and improves the performance of the supercapacitor; and the surface of the fiber has a large number of oxygen-containing functional groups, which can absorb water molecules in the environment, Generate more water and hydrogen ions, and the graphene oxide / fiber composite electrolyte after absorbing water molecules w...

Embodiment 2

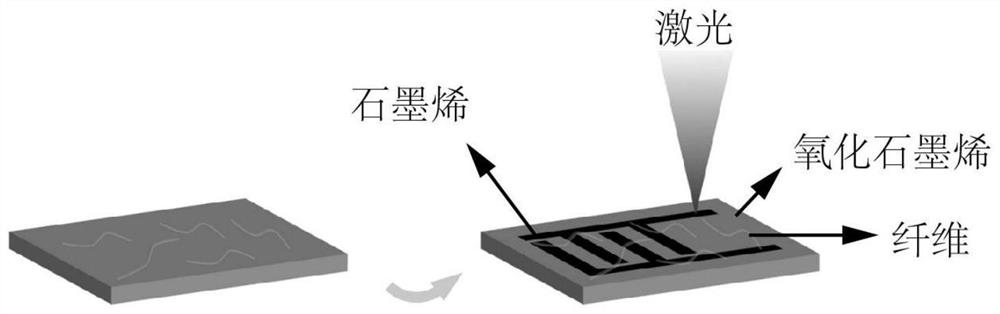

[0052] Such as figure 2 Shown, a kind of preparation method of the highly flexible graphene-based supercapacitor based on laser processing, concrete steps are as follows:

[0053] (1) At room temperature, weigh 2g of graphite, 2g of sodium nitrate and 12g of potassium permanganate; transfer the weighed graphite and sodium nitrate to a 1000mL glass beaker, weigh 100mL of concentrated sulfuric acid through a 100mL graduated cylinder, and Transfer to a beaker, put the stirrer into the beaker, and stir in a constant temperature heating magnetic stirrer; the temperature is 0°C, and the rotation speed is set to 400 rpm; slowly put 12g of potassium permanganate into the medicine spoon within 30 minutes ;Stir for 90 minutes after the addition; adjust the temperature of the constant temperature heating magnetic stirrer to 35°C, and continue stirring for 2 hours after the temperature rise is completed;

[0054] Slowly add 80mL of deionized water dropwise with a rubber dropper, and add...

Embodiment 3

[0070] The preparation process of the highly flexible graphene-based supercapacitor based on laser processing in this embodiment is as follows:

[0071] (1) At room temperature, weigh 2.1 g of graphite, 2.1 g of sodium nitrate and 12.6 g of potassium permanganate. Transfer the weighed graphite and sodium nitrate to a 1000 mL glass beaker. Weigh 100.8mL of concentrated sulfuric acid through a graduated cylinder and transfer it into a beaker. Put the stirring bar into the beaker and stir in a constant temperature heating magnetic stirrer. The temperature was 1 °C, and the rotation speed was set at 400 rpm. Slowly put 12.6g of potassium permanganate into the medicine spoon within 30min. After the addition, stir for another 90 minutes. Adjust the temperature of the constant temperature heating magnetic stirrer to 36°C, and continue stirring for 2 hours after the temperature rise is completed;

[0072] Slowly add 84mL of deionized water dropwise using a rubber-tip dropper, slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com