Waltheria indica microemulsion as well as preparation method and application thereof

A technology of scorpion and microemulsion, which is applied in the field of botanical pesticides, can solve problems such as poor control and loss, and achieve the effects of suppressing deterioration, reducing costs, and ensuring environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

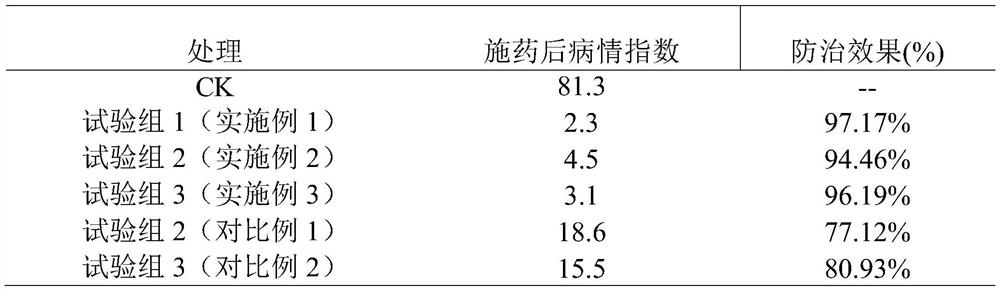

Examples

Embodiment 1

[0027] The preparation of embodiment 1 snake woman microemulsion

[0028] 1.1 Preparation of Snakewort Extract

[0029] Crush the aboveground part of Shepozi and pass it through a 40-mesh sieve to obtain a powder; soak and extract the crushed product with ethyl acetate and methanol at a volume ratio of 1:5 for 24 hours; the solid-liquid ratio of the crushed product to ethyl acetate and methanol kg / L is 1:6, then filter to get the clear liquid, evaporate to dryness with a rotary evaporator at 50°C, and concentrate the extract into a paste to obtain the extract of Snakewort. Repeat this three times to get the Snake Lady extract.

[0030] 1.2 Formula

[0031] 5% of Snakewort extract, 10% of organic solvent, 10% of emulsifier, and 75% of water.

[0032] Ethyl acetate, ethanol and methanol at a mass ratio of 1:1:5 as organic solvents, castor oil polyoxyethylene ether 40, polyoxyethylene oleate and dodecylamine polyoxyethylene at a mass ratio of 2:1:1 Ether is the emulsifier, a...

Embodiment 2

[0039] The preparation of embodiment 2 snake woman microemulsion

[0040] 1.1 Preparation of Snakewort Extract

[0041] Crush the aboveground part of Shepozi and pass through a 40-mesh sieve to obtain a powder; soak and extract the crushed product with ethyl acetate and methanol at a volume ratio of 1:4 for 36 hours; the solid-liquid ratio of the crushed product to ethyl acetate and methanol kg / L is 1:5, then filter to get the clear liquid, evaporate to dryness with a rotary evaporator at 50°C, and concentrate the extract into a paste to obtain the extract of Snakewort. Repeat this three times to get the Snake Lady extract.

[0042] 1.2 Formula

[0043] 5% of Snakewort extract, 10% of organic solvent, 10% of emulsifier, and 75% of water.

[0044] Ethyl acetate, ethanol and methanol at a mass ratio of 1:0.8:6 as organic solvents, castor oil polyoxyethylene ether 40, polyoxyethylene oleate and dodecylamine polyoxyethylene at a mass ratio of 2:0.8:1.2 Ether is the emulsifier...

Embodiment 3

[0051] The preparation of embodiment 3 cobra microemulsion

[0052] 1.1 Preparation of Snakewort Extract

[0053] Crush the aboveground part of Shepozi and pass it through a 40-mesh sieve to obtain a powder; soak and extract the crushed product with ethyl acetate and methanol at a volume ratio of 1:6 for 18 hours; the solid-liquid ratio of the crushed product to ethyl acetate and methanol kg / L is 1:7, then filter to get the clear liquid, evaporate to dryness with a rotary evaporator at 50°C, and concentrate the extract into a paste to obtain the extract of Snakewort. Repeat this three times to get the Snake Lady extract.

[0054] 1.2 Formula

[0055] 5% of Snakewort extract, 10% of solvent, 10% of emulsifier, and 75% of water.

[0056] Ethyl acetate, ethanol and methanol at a mass ratio of 1:1.2:4 are used as solvents, castor oil polyoxyethylene ether 40, polyoxyethylene oleate and dodecylamine polyoxyethylene ether at a mass ratio of 2:1.2:0.8 For the emulsifier, choose ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com