Talcum powder composition and preparation method thereof

A composition and talcum powder technology, applied in the field of daily chemicals, can solve problems such as chemical monomer residues, skin allergies, dermatitis, and poor fluidity, and achieve the goal of repairing damaged skin, inhibiting inflammation, and ensuring safety and mildness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

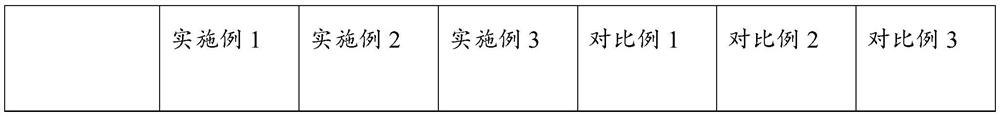

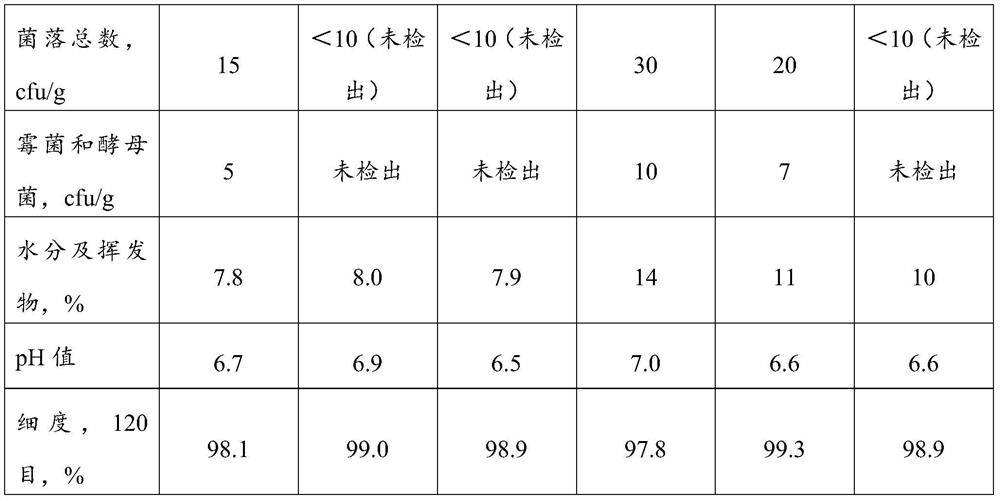

Examples

Embodiment 1

[0028] A talcum powder composition, in parts by weight, comprising 80 parts of illite powder, 16.4 parts of masson pine pollen, 0.5 part of zinc citrate, 0.5 part of hydroxyapatite, 0.1 part of phlox leaf extract, and luohan cypress branch extract 1.0 parts, 0.5 parts of sodium azulene sulfonate and 1.0 parts of peppermint essential oil.

[0029] Among them, the fineness of illite powder is 8000 meshes, the fineness of pine pollen is 325 meshes, the fineness of phlox leaf extract is 120 meshes, the fineness of zinc citrate is 120 meshes, and the fineness of hydroxyapatite is 1250 meshes.

[0030] Prepare above-mentioned talcum powder composition, step is as follows:

[0031] (1) Mix the extract of Cypress grosvenori and 40% peppermint essential oil evenly to obtain prefabricated liquid A; dissolve sodium alkene sulfonate in the remaining peppermint essential oil to obtain prefabricated liquid B;

[0032] (2) Clean and sterilize the blender in advance; weigh bamboo leaf extrac...

Embodiment 2

[0036] A talcum powder composition, in parts by weight, comprising 80 parts of illite powder, 15.4 parts of masson pine pollen, 0.5 part of zinc citrate, 0.5 part of hydroxyapatite, 0.1 part of phlox leaf extract, and luohan cypress branch extract 2.0 parts, 0.5 parts of sodium azulene sulfonate and 1.0 parts of peppermint essential oil.

[0037] Among them, the fineness of illite powder is 8000 meshes, the fineness of pine pollen is 325 meshes, the fineness of phlox leaf extract is 120 meshes, the fineness of zinc citrate is 120 meshes, and the fineness of hydroxyapatite is 1250 meshes.

[0038] Prepare above-mentioned talcum powder composition, method step is the same as embodiment 1.

Embodiment 3

[0040] A talcum powder composition, in parts by weight, comprising 80 parts of illite powder, 14.4 parts of masson pine pollen, 0.5 parts of zinc citrate, 1.5 parts of hydroxyapatite, 0.1 part of phlox leaf extract, and luohan cypress branch extract 2.0 parts, 0.5 parts of sodium azulene sulfonate and 1.0 parts of peppermint essential oil.

[0041] Among them, the fineness of illite powder is 8000 meshes, the fineness of pine pollen is 325 meshes, the fineness of phlox leaf extract is 120 meshes, the fineness of zinc citrate is 120 meshes, and the fineness of hydroxyapatite is 1250 meshes.

[0042] Prepare above-mentioned talcum powder composition, method step is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com