V-FeS/IF electrocatalytic material and preparation method thereof

An electrocatalytic material, v-fes technology, applied in the field of V-FeS/IF electrocatalytic material and its preparation, can solve the problems of low content, high price, hindering the development and application of precious metal-based catalysts, etc., and achieves simple process and low cost. Low, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

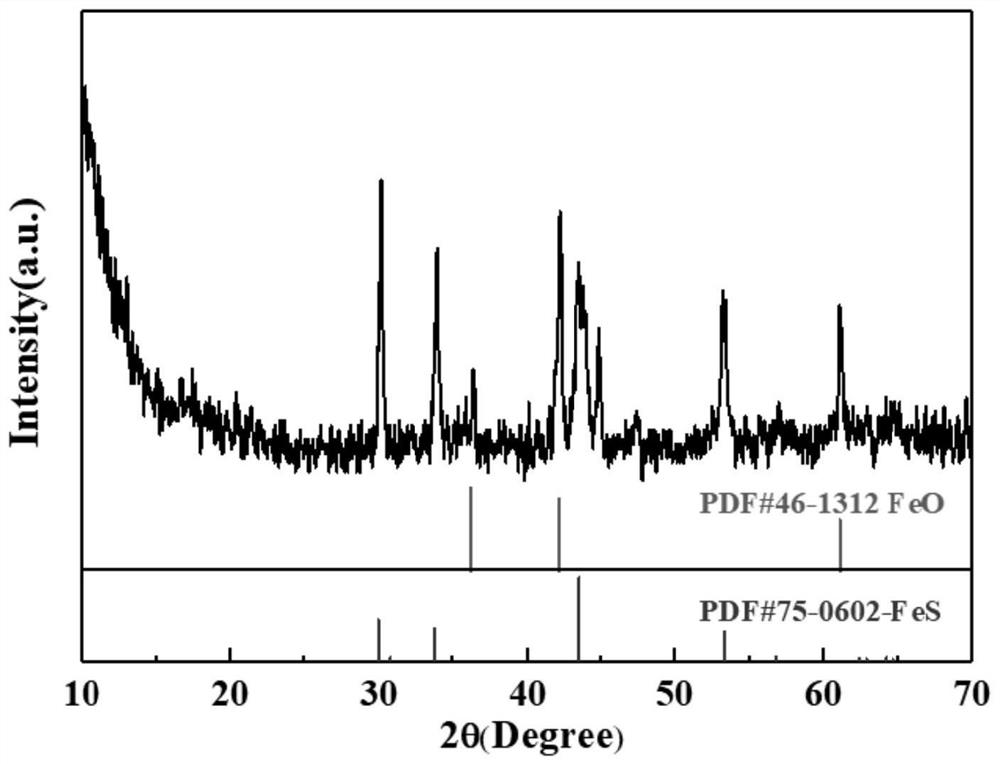

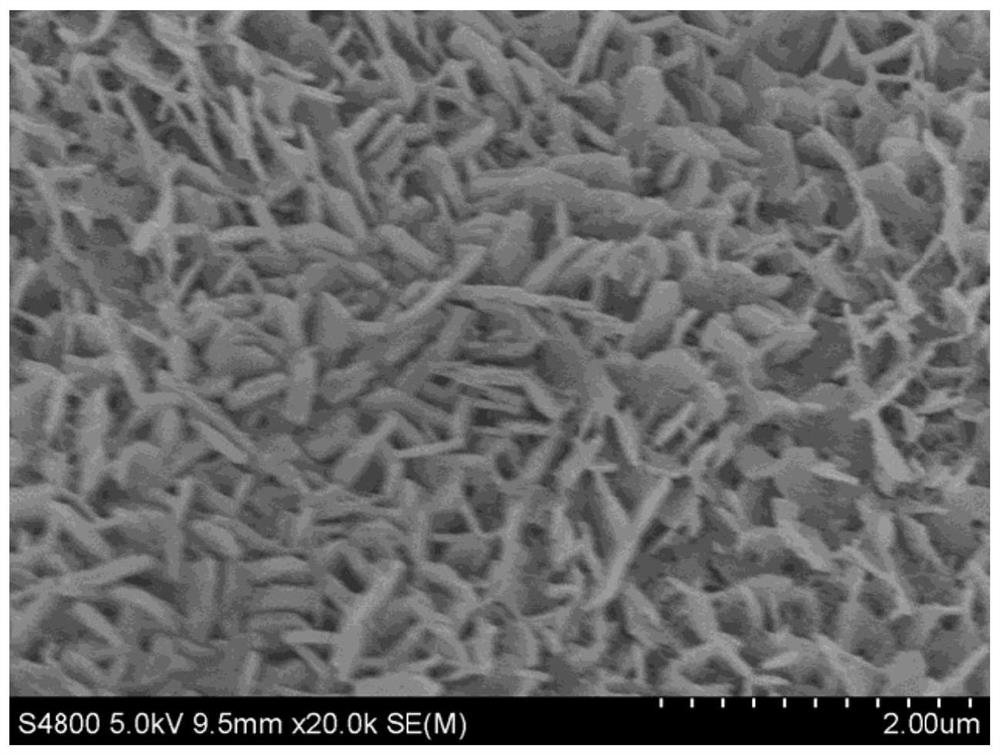

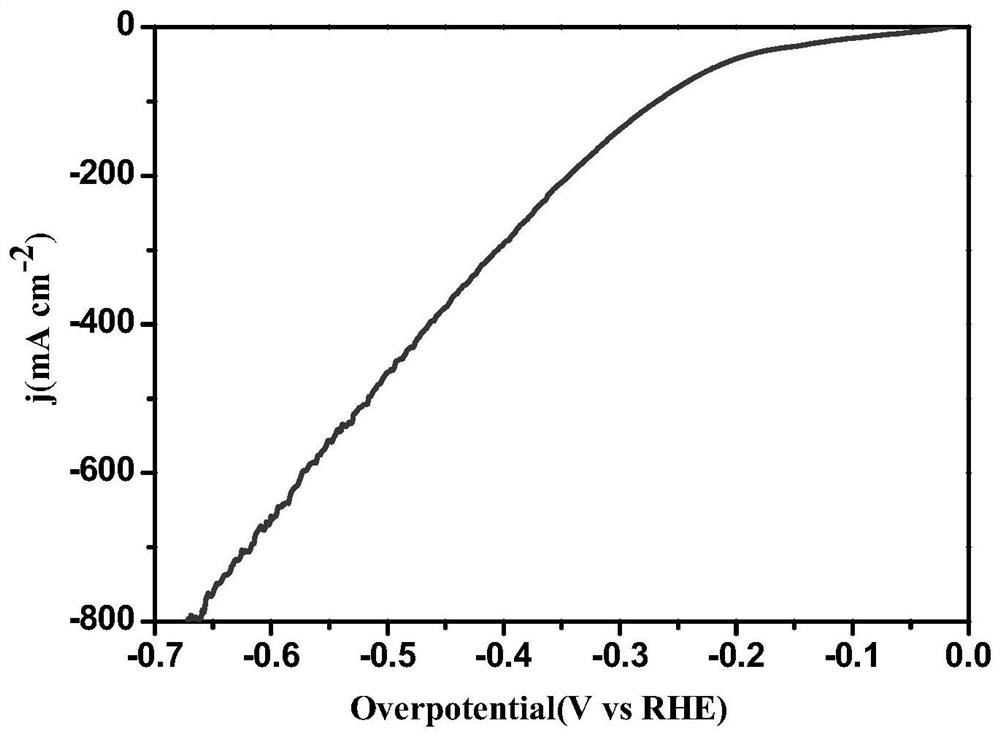

[0024] The present invention adopts a simple one-step hydrothermal method to synthesize a vanadium-doped ferrous sulfide (V-FeS / IF) electrocatalytic material loaded on foam iron with high-efficiency hydrogen evolution, and the synthesized V-FeS / IF electrocatalytic material The structure is controllable, and it exhibits good HER electrocatalytic performance in alkaline solution. The preparation method of the V-FeS / IF electrocatalytic material comprises the following steps:

[0025] ① Weigh 200-600 mg of sodium metavanadate (NaVO 3 ) and 350-650 mg of thioacetamide (TAA), of which, sodium metavanadate (NaVO 3 ) and thioacetamide (TAA) in a molar ratio of 1: (1 to 5) for mixing to obtain a mixture, and then add the mixture to a mixed solution of absolute ethanol and isopropanol, wherein absolute ethanol and isopropanol The volume ratio of alcohol is 1: (0-4), and stirred for 20-60 minutes to form a uniformly mixed solution A.

[0026] ② Add 10-100 mg of polyvinylpyrrolidone to...

Embodiment 1

[0034] ①Weigh 243mg of sodium metavanadate (NaVO 3 ) and 601 mg of thioacetamide (TAA), of which sodium metavanadate (NaVO 3 ) and thioacetamide (TAA) were mixed at a molar ratio of 1:4, and then the mixture was added to only 25ml of absolute ethanol as a solvent, and stirred for 20min to form a uniformly mixed solution A.

[0035] ② Add 10 mg of polyvinylpyrrolidone to the uniformly mixed solution A, and stir it magnetically for 1 hour to obtain solution B.

[0036]③ Pour the solution B into a polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 50%.

[0037] ④Take a 500mL beaker, cut the foam iron into a block of 1cm×5cm, put the cut foam iron into the beaker, pour the acetone solution submerged in the foam iron, ultrasonicate for 10min, then pour out the acetone solution, Pour into the beaker the HCl solution (3mol / L) that has not passed the foam iron, and ultrasonic treatment for 15min, then pour out the HCl solution, then pour the deionized water...

Embodiment 2

[0042] ① Weigh 305 mg of sodium metavanadate (NaVO 3 ) and 563mg of thioacetamide (TAA), of which sodium metavanadate (NaVO 3 ) and thioacetamide (TAA) in a molar ratio of 1:3, then the mixture was added to a mixed solvent of 6ml absolute ethanol and 24ml isopropanol, wherein the volume ratio of absolute ethanol and isopropanol was 1:4, stirred for 60 minutes to form a uniformly mixed solution A.

[0043] ② Add 100 mg of polyvinylpyrrolidone to the uniformly mixed solution A, and stir it magnetically for 5 hours to obtain solution B.

[0044] ③ Pour the solution B into a polytetrafluoroethylene-lined autoclave, keeping the volume filling ratio at 60%.

[0045] ④Take a 500mL beaker, cut the foam iron into a block of 1cm×5cm, put the cut foam iron into the beaker, pour the acetone solution submerged in the foam iron, ultrasonicate for 30min, then pour out the acetone solution, Pour into the beaker the HCl solution (6mol / L) that has not passed the foam iron, and ultrasonic tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com