Spiral sapphire fiber bragg grating, preparation method and application thereof

A fiber Bragg and Bragg grating technology, applied in the directions of cladding fiber, grating fiber, optical waveguide light guide, etc., can solve the problems of reflection peak reflectivity change, spectral instability, etc., and achieve easy operation, high coupling efficiency, and good spectral performance. and the effect of spectral stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

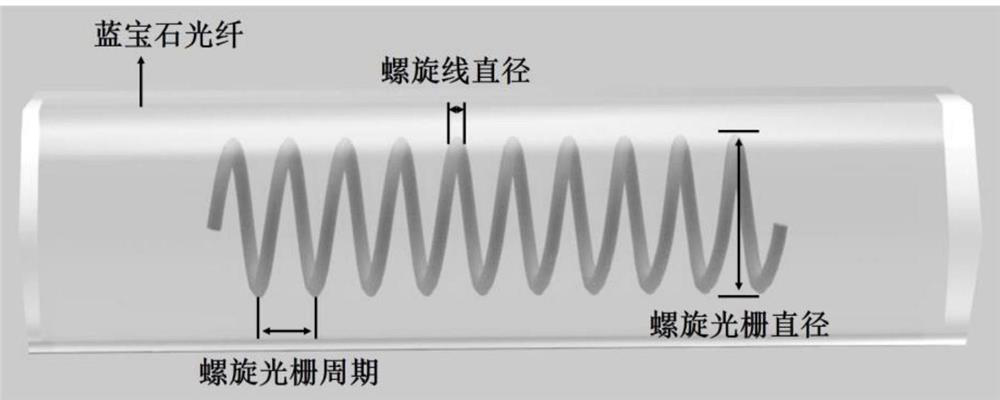

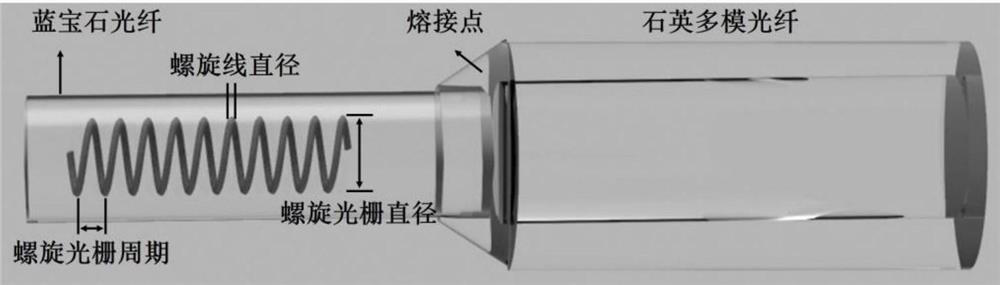

[0047] A spiral sapphire fiber Bragg grating, the spiral sapphire fiber Bragg grating is a sapphire fiber comprising a spiral Bragg grating; the spiral Bragg grating is a three-dimensional spring-shaped helical structure as a whole, symmetrically distributed along the axial direction of the sapphire fiber The spiral Bragg grating is obtained by scanning the femtosecond laser point by point along the spring-shaped trajectory inside the sapphire fiber, and the spiral Bragg grating formed after laser modulation is a permanent modulation area of refractive index.

[0048] The modulated refractive index of the spiral Bragg grating is lower than that of the area in the sapphire fiber that is not modulated by the laser, and the difference between the refractive index and the unmodulated area is 0.001-0.1; the grating is modulated by the laser from Single crystals transform into polycrystalline or amorphous states.

[0049] The three-dimensional spiral structure of the spiral Bragg ...

Embodiment 2

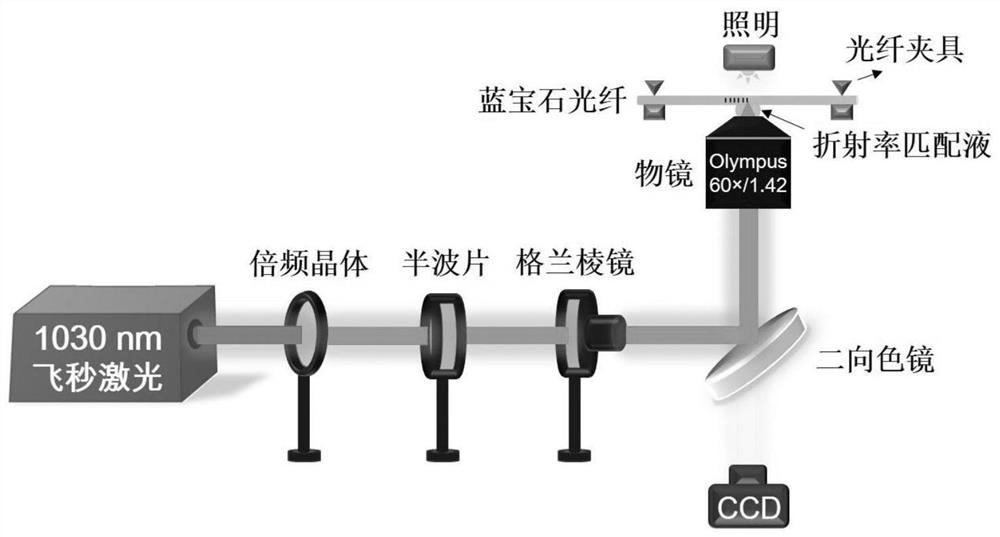

[0051] This embodiment provides a method for preparing a helical sapphire fiber Bragg grating. A true three-dimensional helical Bragg grating is prepared inside the sapphire fiber through a femtosecond laser processing system. The helical Bragg grating has good structural symmetry and The large refractive index modulation area can obtain stable spectra with high reflectivity and high quality. The specific steps are as follows:

[0052] (1), optical fiber pretreatment:

[0053] First, take a 30cm-long, 60μm-diameter sapphire fiber, and clean the sapphire fiber as a whole with alcohol cotton;

[0054] (2), optical fiber placement:

[0055] Place the cleaned sapphire fiber in step (1) on the femtosecond laser processing platform (Aerotech, model ABL10050L), adjust the position of the fiber so that the sapphire fiber is immersed in the refraction above the oil immersion objective lens (Olympus, 60× / 1.42) In the ratio matching solution (refractive index value 1.75), and then use ...

Embodiment 3

[0067] The spiral sapphire fiber Bragg grating prepared in embodiment 2 is subjected to a bending test, and the specific test steps are as follows:

[0068] In order to verify the spectral stability of the spiral grating, Figure 7 It is the result of the helical sapphire fiber Bragg grating changing with different bending radii. When the bending radius is gradually reduced to 10mm, the spectral reflectance remains basically unchanged. When continuing to bend the sapphire fiber, when the bending radius reaches 5mm, the spectral reflectance decreases slightly, and the spectrum becomes smoother compared with the unbent, mainly because the bending process will filter out a part of the high-order modes in the sapphire fiber, thus The spectrum is smoothed and the spectral bandwidth is reduced accordingly. The bending test shows that the spiral grating has good spectral stability. When the external disturbance redistributes the mode field intensity in a certain range, it can stil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com