Gel electrode doped with polyaniline in situ and preparation method and application of gel electrode

An in-situ doping and polyaniline technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of losing lignin oxygen-containing groups, unfavorable electrolyte ion adsorption, and complicated activation process, etc., to achieve Achieve large-scale production, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

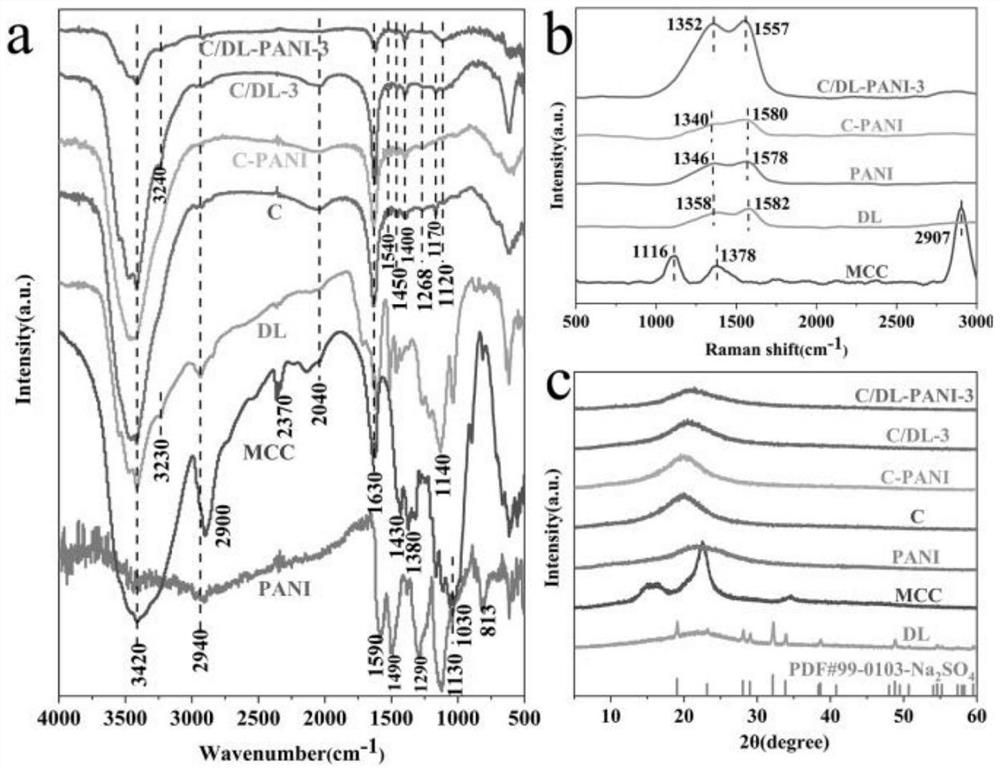

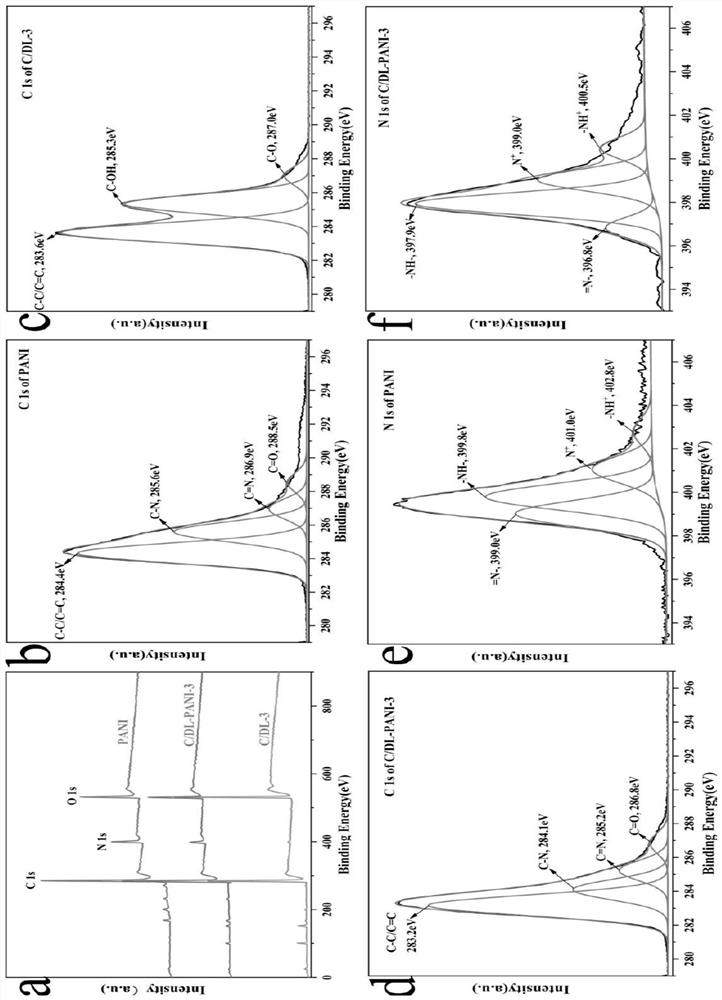

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 microcrystalline cellulose / dealkalized lignin (C / DL-1) airgel

[0041] 0.250g MCC was added to 10mL solution of 7% NaOH / 12% urea / 81% distilled water, stirred at -12°C for 30 minutes to form MCC solution; then 0.250g DL was added to dissolve in MCC solution. After DL was completely dissolved, a C / DL solution was obtained; 27.36 mmol ECH was added to the C / DL solution, and stirred rapidly for 1 hour to form a uniform solution, then transferred to a 75 mm polytetrafluoroethylene mold and cross-linked at 90 °C for 6 h, and then used Acetone and distilled water were repeatedly washed to pH 7 to obtain C / DL-1 hydrogel; after freeze-drying, C / DL-1 airgel was obtained.

Embodiment 2

[0042] Embodiment 2 Preparation of microcrystalline cellulose / dealkalized lignin (C / DL-2) airgel

[0043] 0.333g MCC was added to 10mL solution of 7% NaOH / 12% urea / 81% distilled water, stirred at -12°C for 30 minutes to form MCC solution; then 0.167g DL was added to dissolve in MCC solution. After DL was completely dissolved, a C / DL solution was obtained; 27.36 mmol ECH was added to the C / DL solution, and stirred rapidly for 1 hour to form a uniform solution, then transferred to a 75 mm polytetrafluoroethylene mold and cross-linked at 90 °C for 6 h, and then used Acetone and distilled water were repeatedly washed to pH 7 to obtain C / DL-2 hydrogel; after freeze-drying, C / DL-2 airgel was obtained.

Embodiment 3

[0044] Embodiment 3 Preparation of microcrystalline cellulose / dealkalized lignin (C / DL-3) airgel

[0045] Add 0.375g MCC to 10mL solution of 7% NaOH / 12% urea / 81% distilled water, stir at -12°C for 30 minutes to form MCC solution; then add 0.125g DL to dissolve in the MCC solution; after DL is completely dissolved , to obtain a C / DL solution; add 27.36mmol ECH to the C / DL solution, stir rapidly for 1 hour, transfer to a 75mm polytetrafluoroethylene mold after forming a uniform solution, and cross-link at 90°C for 6h, repeat with acetone and distilled water After washing to pH 7, C / DL-3 hydrogel was obtained; after freeze-drying, C / DL-3 aerogel was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com