Silicon-carbon negative electrode material, preparation method and application

A negative electrode material, silicon carbon technology, applied in the field of energy storage electrode materials, can solve the problems of high preparation cost of ultrafine nano silicon, poor process controllability, volume expansion, etc., and achieves favorable rate and cycle performance, excellent cycle performance, The effect of reducing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

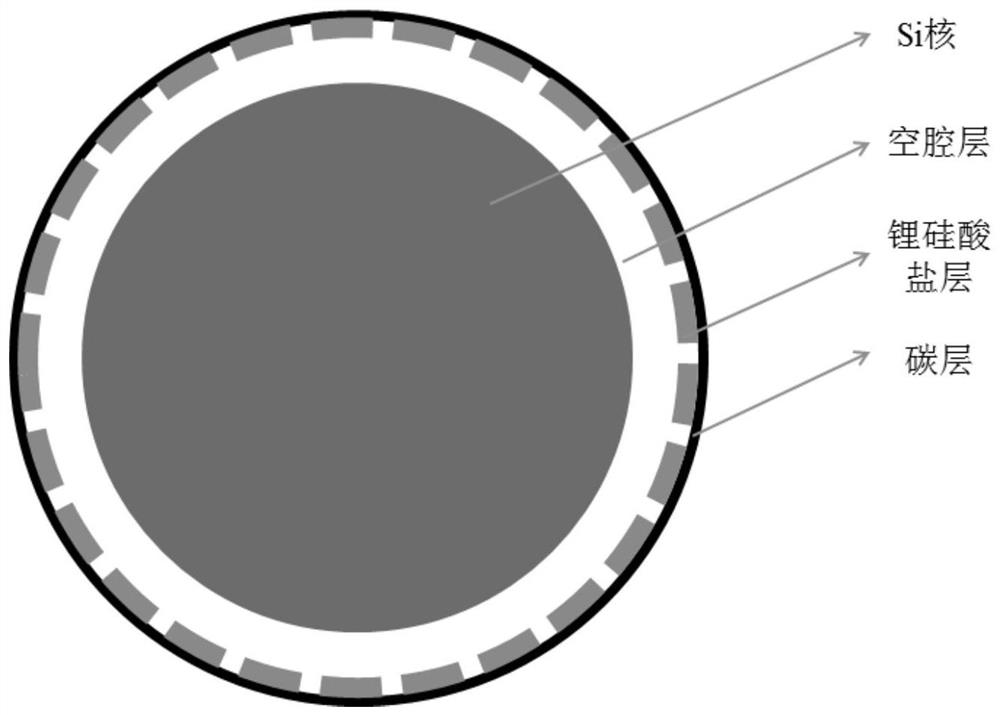

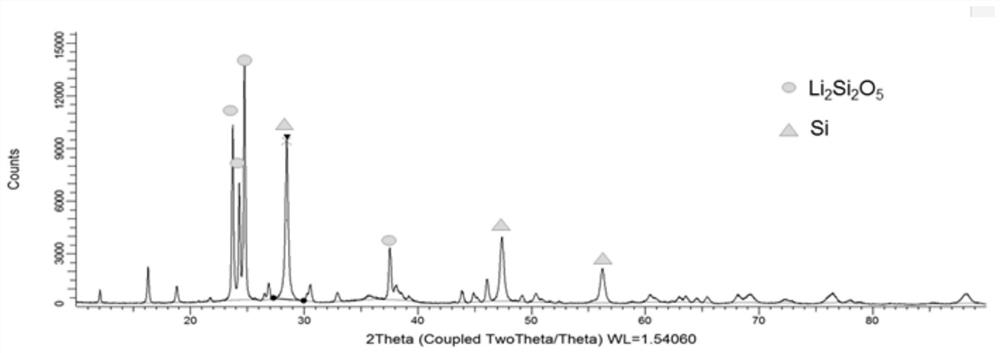

[0062] A silicon-carbon negative electrode material, the composite material is a core-shell structure, and the core-shell structure is sequentially composed of a silicon core, a cavity layer, a lithium silicate layer, and a carbon layer from the inside to the outside, and the silicon core is a micron silicon , micropores are distributed on the lithium silicate layer, and the carbon layer covers the lithium silicate layer.

[0063] Specifically, the core-shell structure uses micro-silicon as the core, and the outer layer of the micro-silicon core is a cavity layer with a certain thickness. The cavity layer is a spherical cavity, and the outside of the cavity layer is a lithium silicate layer. The silicate layer is non-coated to the cavity layer, and there are micropores distributed on the lithium silicate layer. The micropores penetrate the lithium silicate layer and communicate with the cavity layer. Covered with carbon layer.

[0064] The thickness of the cavity layer is 60n...

Embodiment 2

[0068] A lithium-ion battery includes a silicon-carbon negative electrode material provided by an embodiment of the present invention.

Embodiment 3

[0070] A preparation method of silicon carbon negative electrode material, according to the following steps:

[0071] (1) Oxidation:

[0072] Take by weighing D50 (median particle size) be 0.8um, Dmax be 3kg of micron silicon powder body of 2.0um, add rotary kiln, the filling rate of rotary kiln is 21.6%, rotating speed 0.5r / min, compressed air flow 3L / min, with 5°C / min to 550°C for oxidation treatment for 60 minutes, the surface of the micron silicon powder is oxidized to form a silicon dioxide layer, and then it is naturally cooled to room temperature and taken out.

[0073] (2) Heat treatment:

[0074] After the oxidized micro-silicon powder is sieved with 270 mesh, it is uniformly mixed with lithium hydroxide powder at a molar ratio of 4.0, and then added to the rotary furnace. The rotating speed of the rotary furnace is 0.5r / min, and the rotary furnace Inert gas, heat treatment at 5°C / min to 500°C for 4 hours under an inert atmosphere; then stop heating and cool to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com