Sulfide solid electrolyte, preparation method thereof and lithium ion battery

A solid electrolyte and sulfide technology, applied in the field of lithium ion batteries, can solve the problems of low ionic conductivity, poor stability of air and organic solvents, etc., and achieve the effects of simple preparation process, high stability and excellent lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In another typical implementation of the present application, a method for preparing the aforementioned sulfide solid electrolyte is provided, the preparation method comprising: step S1, weighing Li source, S source, Sb source, I source, optional Si source, and mechanically grind the raw materials comprising Li source, S source, Sb source, I source, and optional Si source to obtain the first mixture; Step S2, in nitrogen , vacuum or inert gas atmosphere, the first mixture is sintered to obtain a sulfide solid electrolyte.

[0027] The first mixture obtained by mechanical grinding is more uniform, and diffusion is formed between the elements; the mixture is sintered in nitrogen, vacuum or inert gas atmosphere to make the binding energy of each element higher, and the structure of the obtained sulfide solid electrolyte It is more stable, and the above-mentioned sulfide solid electrolyte has better lithium ion conductivity at room temperature and higher stability to air an...

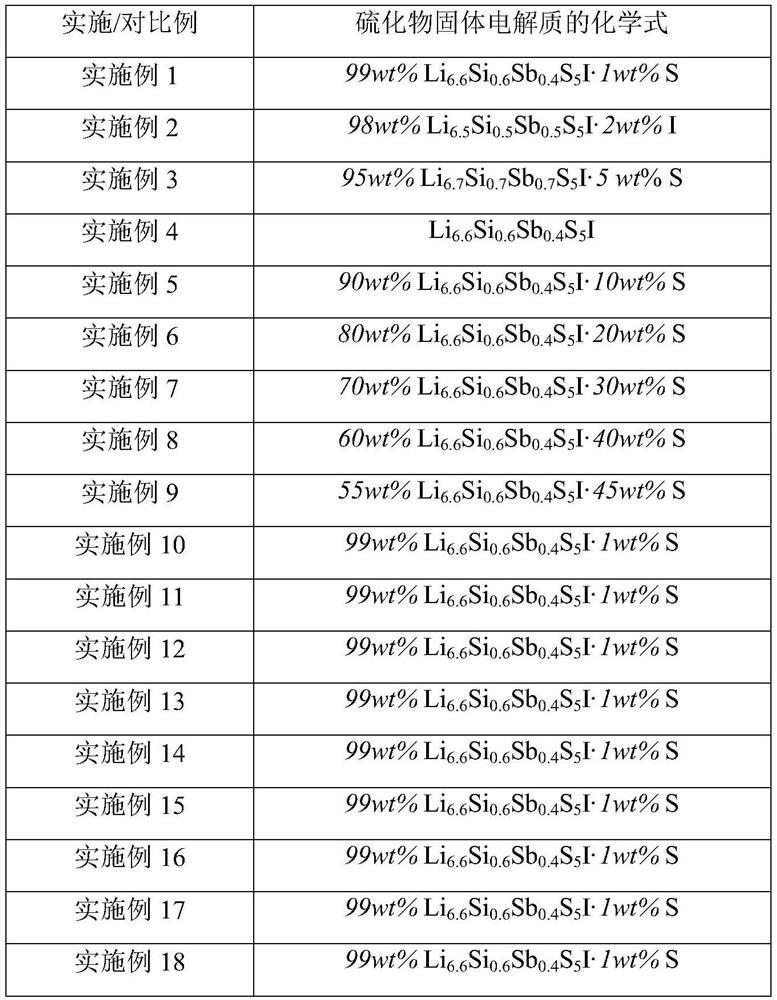

Embodiment 1

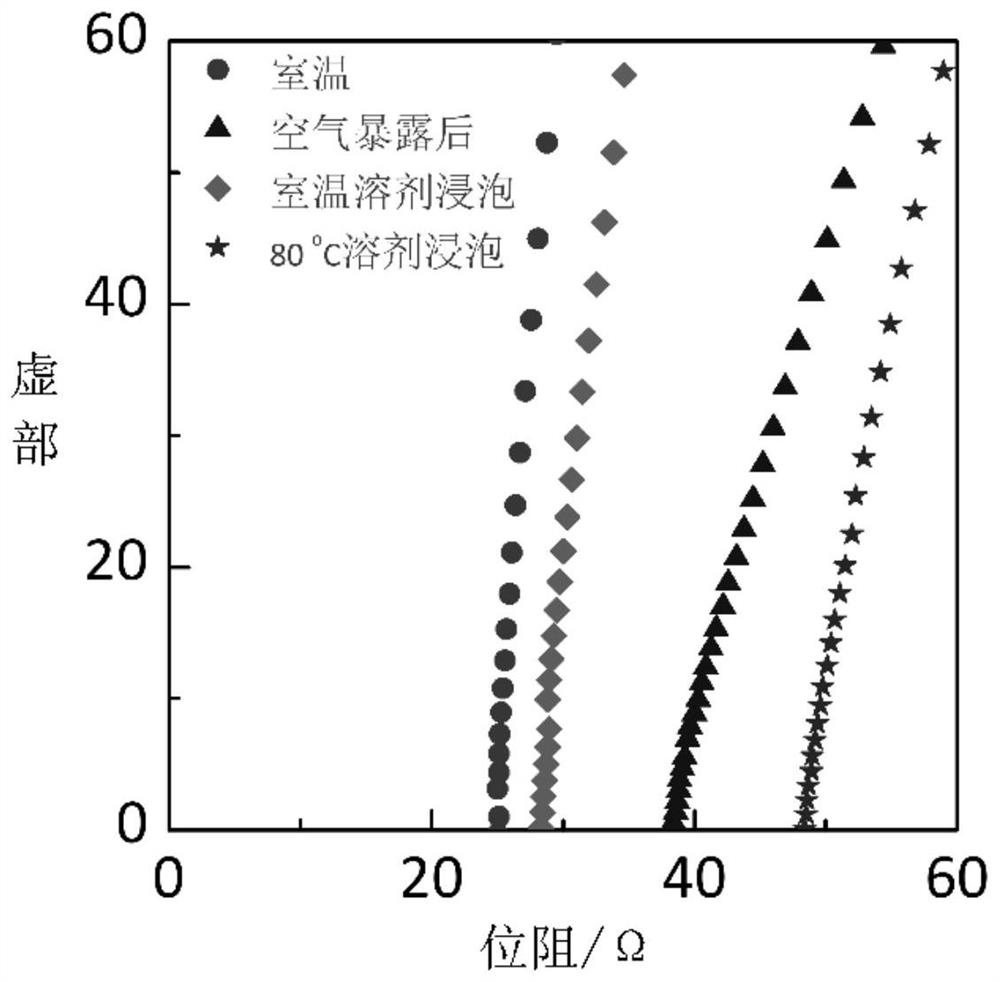

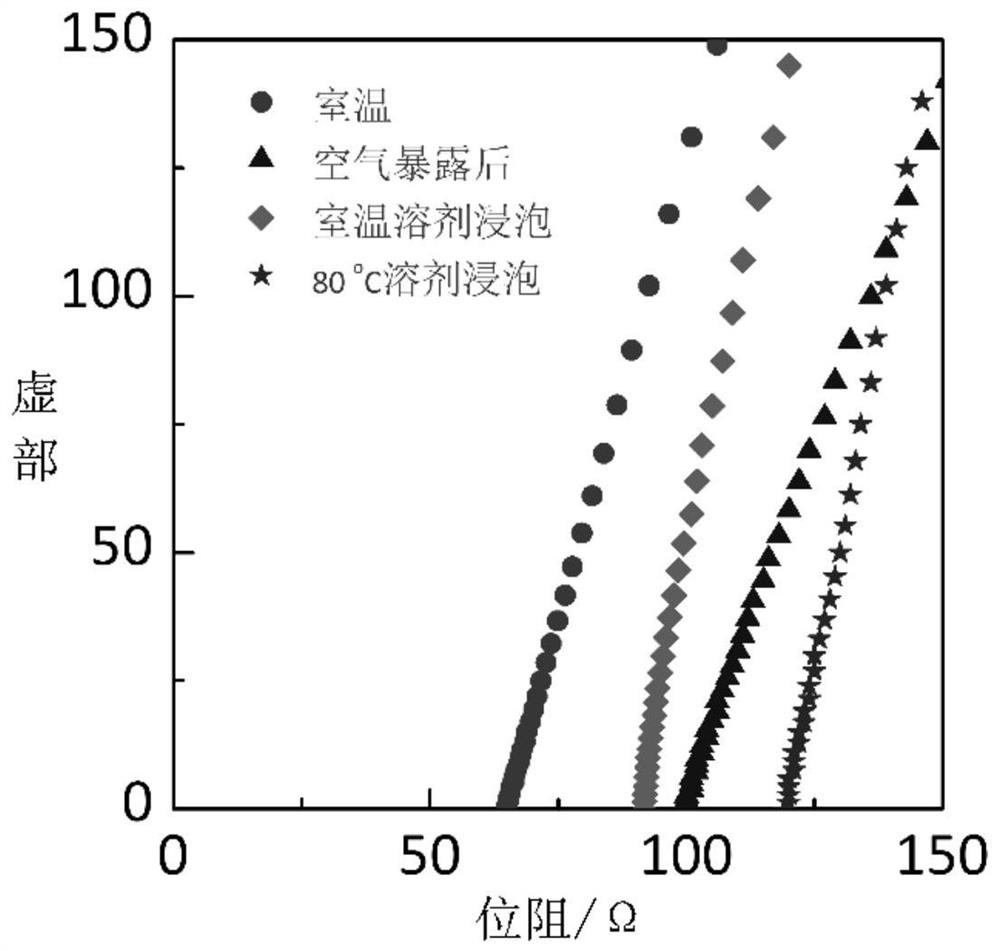

[0040] Will Li 2 S, SiS 2 , Sb 2 S 5 The raw materials of LiI are added to the high-energy ball mill according to the molar ratio of 14:3:1:5, and zirconia balls are added at the same time. The mass ratio of zirconia balls to raw materials is 10:1, and the milling speed is 300r / min. 24 hours of high-energy ball milling to obtain the first mixture. Then add sublimed sulfur powder to the first mixture according to the mass ratio of sublimated sulfur to the first mixture of 1:99 and perform high-energy ball milling again at a high-energy ball milling speed of 300r / min for 2h to obtain the second mixture. Then, the second mixture was sintered at 550° C. for 12 h under an argon atmosphere to obtain a sulfide solid electrolyte. Among them, the room temperature AC test impedance diagram of the sulfide solid electrolyte is shown in figure 1 , the corresponding relationship between the impedance of the sulfide solid electrolyte and its thickness and area is shown in Table 1.

[0...

Embodiment 2

[0044] Will Li 2 S, SiS 2 , Sb 2 S 5 The raw materials of LiI are added to the high-energy ball mill according to the molar ratio of 11:2:1:4, and zirconia grinding balls are added at the same time. The mass ratio of zirconia grinding balls to raw materials is 20:1, and the high-energy ball milling speed is 550r / min. 12 hours of high-energy ball milling to obtain the first mixture. Then, according to the mass ratio of iodine to the first mixture of 2:98, iodine tablets were added to the first mixture and high-energy ball milling was performed again, and the high-energy ball milling was performed at a high-energy ball milling speed of 300r / min for 2h to obtain the second mixture. Then, the second mixture was sintered at 450° C. for 6 h under vacuum to obtain a sulfide solid electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com