Production process and production equipment of microbial fermentation feed for replacing antibiotics

A microbial fermentation technology that replaces antibiotics, applied in the field of livestock and poultry feed, to achieve the effect of improving the use effect and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

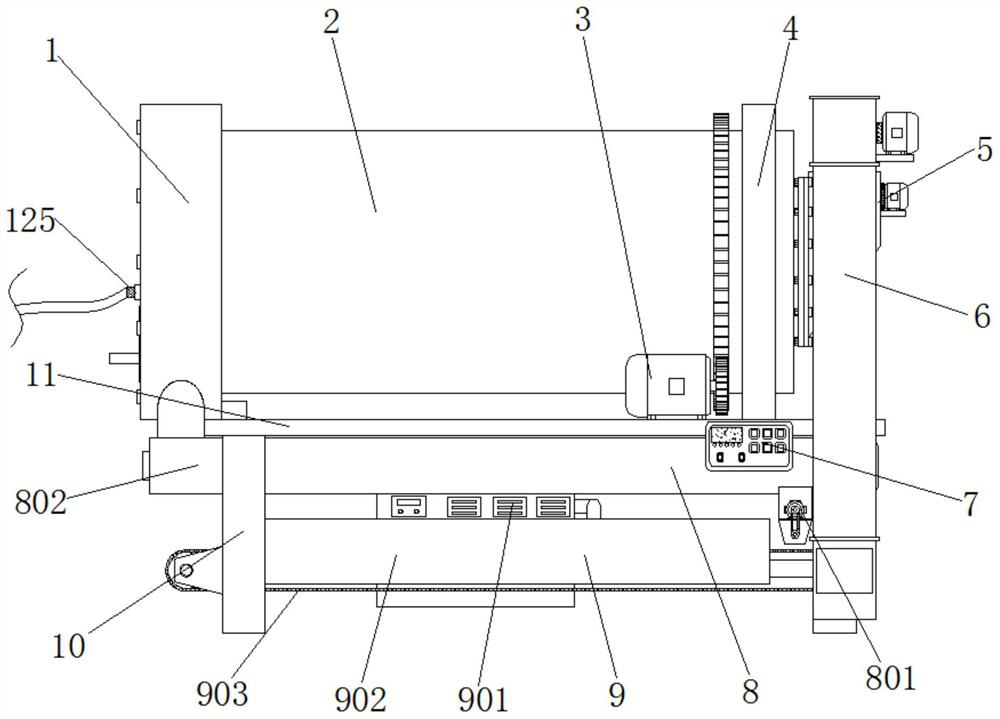

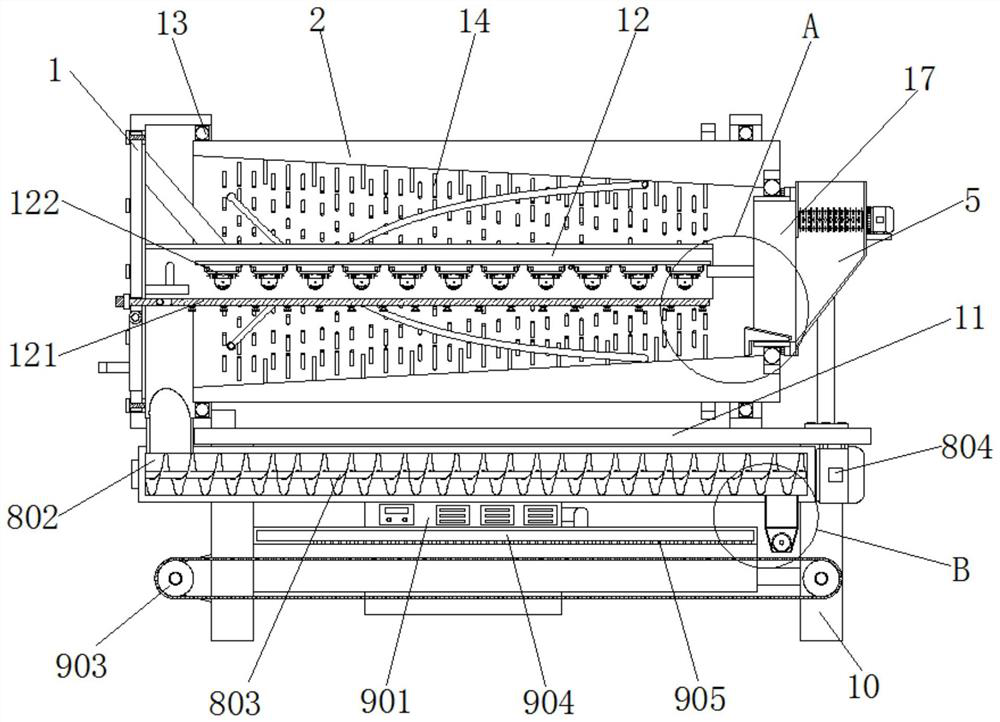

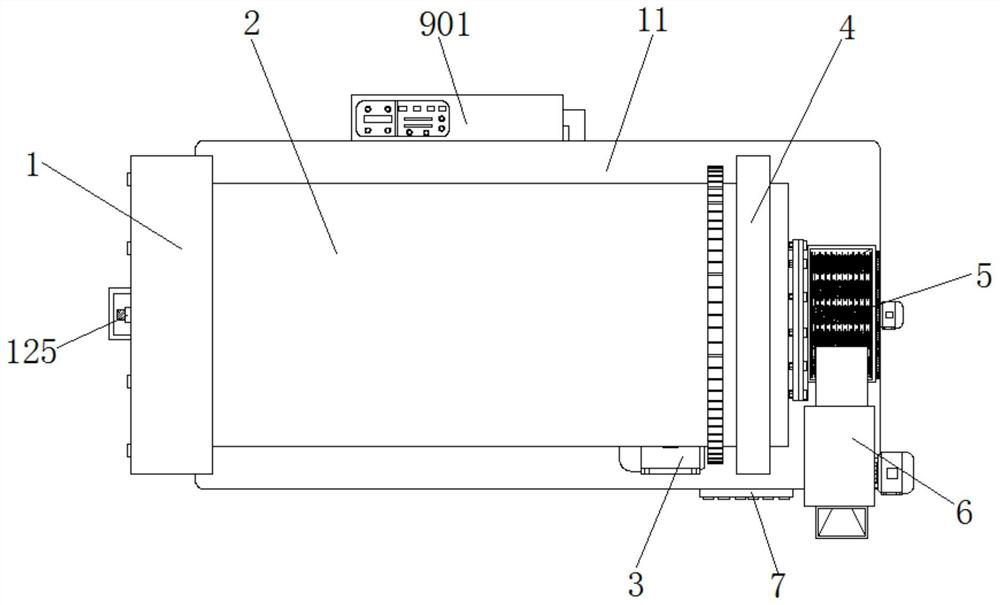

[0047] Example 1, such as Figure 1-10 As shown, first, the bucket elevator 6 is used to transport the mixed feed to the inside of the feed bin 501, and at the same time, the compound medicine is also poured into the inside of the feed bin 501 from above the feed bin 501, at this time, the first drive is controlled The motor 505 drives multiple groups of rotating rollers 503 to rotate at the same time, and the two adjacent groups of rotating rollers 503 are connected by transmission gears 504, so that the adjacent rotating rollers 503 rotate in opposite directions, and the crushing teeth 502 on the outside of the rotating rollers 503 The lumped feed raw materials can be broken quickly, and the crushed feed raw materials enter the interior of the drum 2 and can be fully mixed with the compound medicine. After the mixed feed with the compound medicine enters the interior of the drum 2, it is controlled by the control panel 7 The first driving device 3 drives the drum 2 to rotate...

Embodiment 2

[0048] Example 2, such as Figure 1-10 As shown, the bucket elevator 6 is used to transport the fermented feed to the inside of the drum 2. At this time, the electric heating lamp 122 is controlled to initially heat the feed, and the heated feed is transported to the conveyor belt device 903 through the discharge assembly 8. Utilize the hot air that hot blower 901 produces then to the inside of gas-collecting bin 904, the hot-air inside gas-collecting bin 904 is sprayed on the microbial fermented feed on conveyor belt device 903 surface by jet hole 905, and conveyor belt device 903 in the working process will The feed slowly passes through the inner side of the U-shaped plate 902, and the evenly distributed feed on the conveyor belt device 903 is fully dried by the hot air.

[0049]Working principle: connect the device to the power supply before use, first use the bucket elevator 6 to transport the mixed feed to the inside of the feeding bin 501, and pour the compound medicine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com