Hard carbon negative electrode material of sodium-ion battery based on shell biomass and preparation method of hard carbon negative electrode material

A sodium-ion battery and biomass material technology, applied in the direction of active material electrodes, battery electrodes, carbon preparation/purification, etc., can solve the problem that graphite cannot be used as a negative electrode material of biomass carbon, and the large-scale application production is difficult, and the preparation process is cumbersome and other problems, to achieve the effect of wide and abundant raw material sources, improved reversible capacity, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

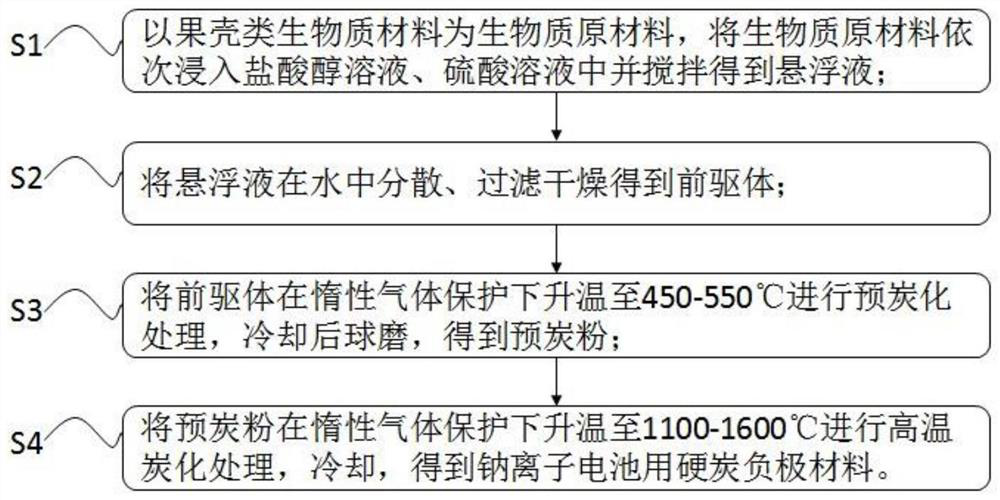

[0039] Such as figure 1 Shown, a kind of preparation method of the sodium-ion battery hard carbon negative electrode material based on husk biomass of the present invention comprises the following steps:

[0040] S1. Using fruit shell biomass materials as biomass raw materials, immerse the biomass raw materials in hydrochloric acid alcohol solution (a mixed solution of dilute hydrochloric acid and ethanol) and sulfuric acid solution in sequence and stir to remove the ash in the biomass raw materials and extract with ethanol The substance is used to oxidize and modify the easily oxidized functional groups in the biomass raw materials to obtain a suspension;

[0041] S2, dispersing the suspension obtained in step S1 in water, filtering and drying to obtain a precursor;

[0042] S3, heating the precursor obtained in step S2 to 450-550°C under the protection of an inert gas for pre-carbonization treatment, and ball milling after cooling to obtain pre-carbon powder;

[0043] S4, ...

Embodiment 1

[0067] The preparation method of the hard carbon negative electrode material for the sodium ion battery based on the husk biomass of the present embodiment, the specific steps are:

[0068] (1) The dried camellia oleifera shell was crushed into powder by a pulverizer, and 10 g of camellia oleifera shell powder was weighed as a biomass raw material, immersed in 60 mL of a mixed solution of 0.5 mol / L dilute hydrochloric acid and 30% ethanol, at room temperature Stir at low temperature for 6 h to remove the ash and ethanol extract in the biomass raw material; filter and add to 60 mL of sulfuric acid with a molar concentration of 6 mol / L, stir at room temperature for 6 h, carry out oxidation modification, and wait for the reaction to complete After that, a brown suspension was obtained;

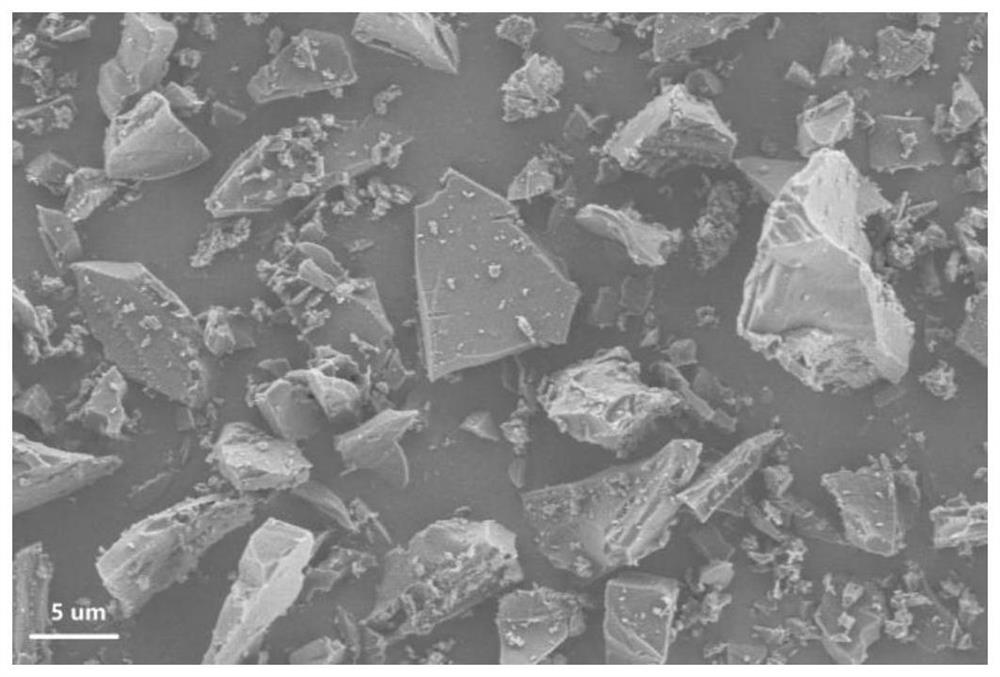

[0069] (2) The obtained brown suspension was ultrasonically dispersed in water for 30 min, filtered and dried to obtain the precursor, and then put into a tube furnace with argon gas for pre-pyro...

Embodiment 2

[0077] The preparation method of the hard carbon negative electrode material for the sodium ion battery based on the husk biomass of the present embodiment, the specific steps are:

[0078] (1) Weigh 10 g of camellia oleifera shell powder as biomass raw material, immerse in 60 mL of a mixed solution of 0.5 mol / L dilute hydrochloric acid and 30% ethanol, stir at room temperature for 6 h, and remove the ash in the biomass raw material and ethanol extract; filtered, added to 60 mL of sulfuric acid with a molar concentration of 6 mol / L, stirred at room temperature for 6 h, and oxidized and modified. After the reaction was completed, a brown suspension was obtained;

[0079] (2) The obtained brown suspension was ultrasonically dispersed in water for 30 min, filtered and dried to obtain the precursor, and then put into a tube furnace with argon gas for pre-pyrolysis and carbonization, and the temperature was raised to 500 °C at 10 °C / min and kept for 2 h, cooled to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com