Functionalized metal organic framework nano material, preparation method and application thereof

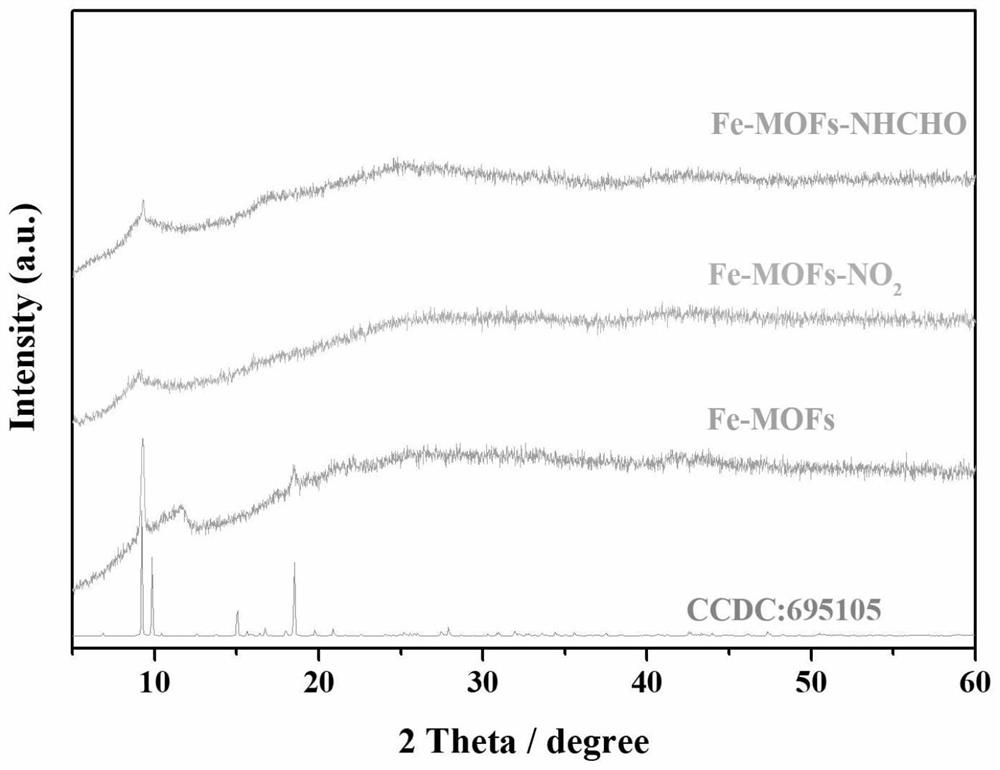

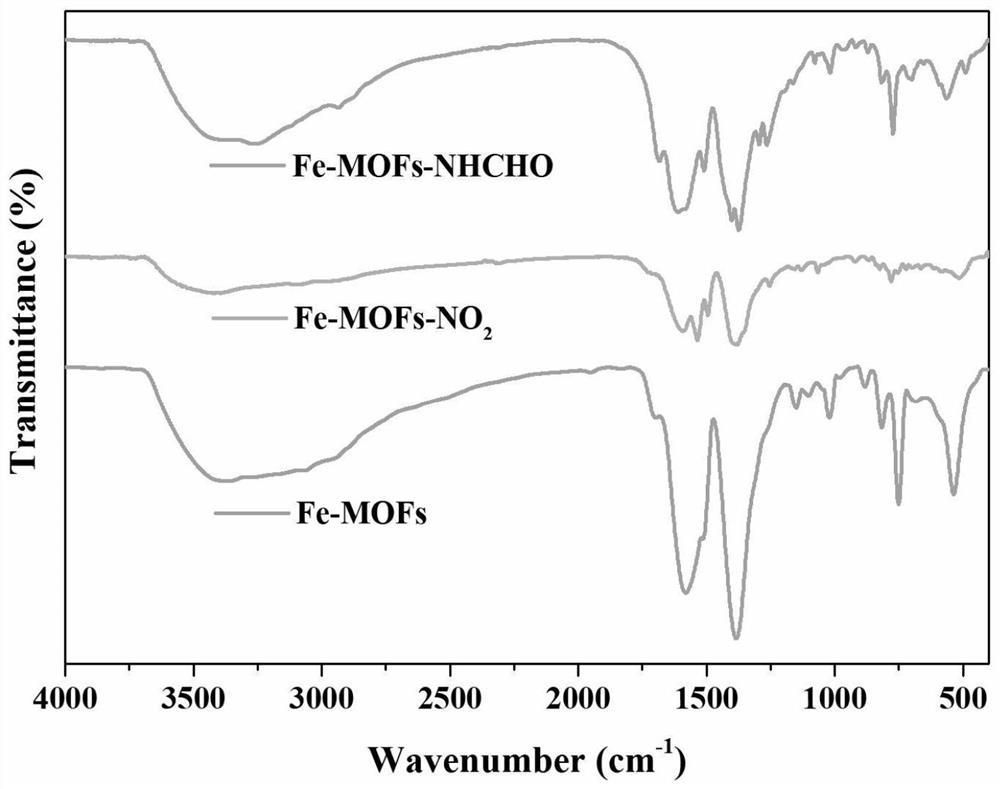

A technology of metal-organic frameworks and nanomaterials, which is applied in the field of functionalized metal-organic framework nanomaterials, preparation and application, can solve the problems of few studies on the influence of organic ligands on electrocatalytic performance, and achieve high electrocatalytic activity and stability , the effect of consistent frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The functionalized metal organic framework nanomaterial, the simplified structural formula of the functionalized metal organic framework nanomaterial is Fe-MOFs-X, X=NO 2 ; The specific structure is as follows:

[0042]

[0043] The preparation method of the functionalized metal organic framework nanomaterial comprises the following specific steps:

[0044] Step 1, dissolve 0.1mmol organic ligand 2-nitroterephthalic acid and 0.1mmol iron salt (iron salt is ferric chloride hexahydrate) in organic solvent (N,N-dimethylacetamide), organic The solid-to-liquid ratio of the ligand to the organic solvent is 1:1g / L, and the reaction product is obtained by heating at 150°C for 3h for hydrothermal reaction;

[0045]Step 2. Cool the reaction product obtained in step 1 to room temperature, filter it through an organic microporous membrane, wash the filtered product with deionized water and ethanol organic solvent in turn, and then dry to obtain the functionalized metal organic ...

Embodiment 2

[0047] The functionalized metal organic framework nanomaterial, the simplified structure of the functionalized metal organic framework nanomaterial is Fe-MOFs-X, X=NHCHO; the specific structure is as follows:

[0048]

[0049] The preparation method of the functionalized metal organic framework nanomaterial comprises the following specific steps:

[0050] Step 1. Dissolve 0.1 mmol of organic ligand 2-formylaminoterephthalic acid and 0.1 mmol of iron salt (iron salt is ferric chloride hexahydrate) in an organic solvent (N,N-dimethylacetamide), The solid-to-liquid ratio of the organic ligand to the organic solvent is 1:0.85g / L, and the reaction product is obtained by heating at 150°C for 3 hours for hydrothermal reaction;

[0051] Step 2. Cool the reaction product obtained in step 1 to room temperature, filter it through an organic microporous membrane, wash the filtered product with deionized water and ethanol organic solvent in turn, and then dry to obtain the functionalize...

Embodiment 3

[0071] The functionalized metal organic framework nanomaterial, the simplified structure of the functionalized metal organic framework nanomaterial is Fe-MOFs-X, X=NHCHO; the specific structure is as follows:

[0072]

[0073] The preparation method of the functionalized metal organic framework nanomaterial comprises the following specific steps:

[0074] Step 1. Dissolve 0.1 mmol of organic ligand 2-formylaminoterephthalic acid and 0.1 mmol of iron salt (iron salt is ferric chloride hexahydrate) in an organic solvent (N,N-dimethylacetamide), The solid-to-liquid ratio of the organic ligand to the organic solvent is 1:0.5g / L, and the reaction product is obtained by heating at 150°C for 5h for hydrothermal reaction;

[0075] Step 2. Cool the reaction product obtained in step 1 to room temperature, filter it through an organic microporous membrane, wash the filtered product with deionized water and ethanol organic solvent in turn, and then dry to obtain the functionalized meta...

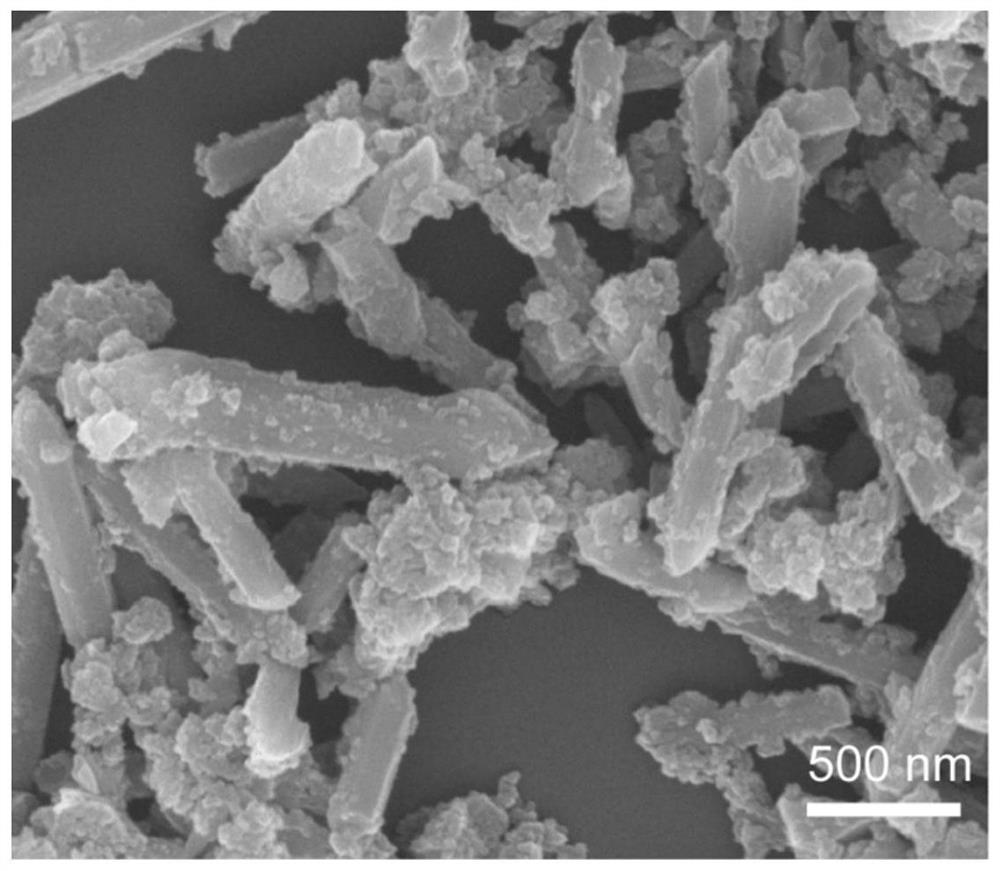

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com