Power plant condensing system and process method

A technology for condensing systems and power plants, which is applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problems of complex anti-corrosion and anti-scaling processes, large use of circulating water, and high waste water treatment costs, and achieve economic and environmental benefits. Significant, reduced equipment footprint, reduced equipment cost and footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

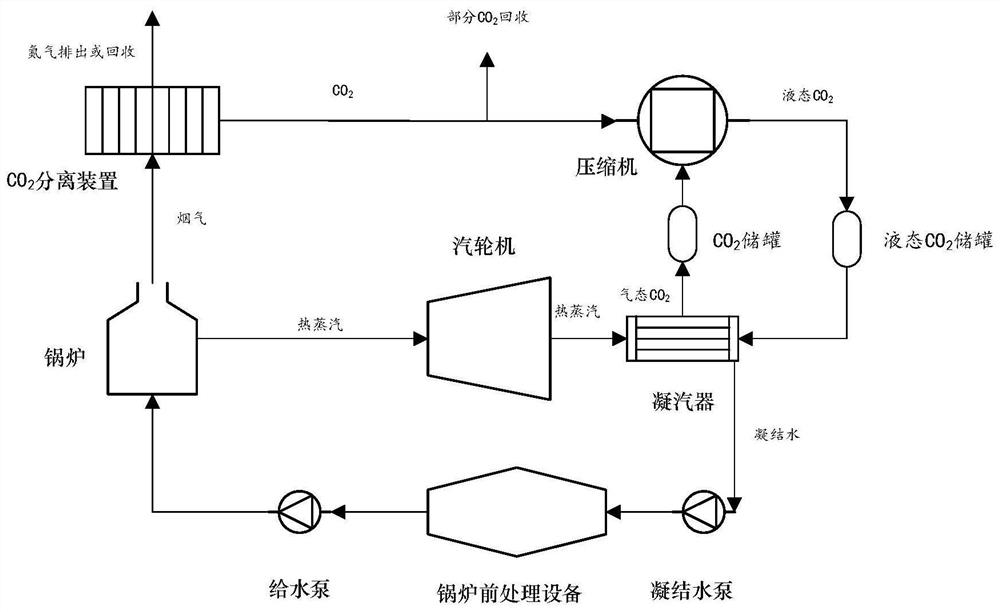

[0029] refer to figure 1 As shown, this embodiment provides a steam condensation system of a power plant, including: a steam turbine, a compressor, and a condenser, the steam turbine includes a steam turbine outlet, and the steam turbine outlet is used to discharge steam; the compressor includes a first compressor machine inlet, compressor outlet; the condenser includes a condenser steam inlet, a condenser medium inlet, a condenser drain, and a condenser outlet, the hot steam inlet is connected to the steam turbine outlet, and the The condenser medium inlet is connected to the compressor outlet, and the condenser medium inlet is used to input liquid carbon dioxide, and the condenser exhaust port is connected to the first compressor inlet; using liquid carbon dioxide as the cooling medium, the condenser In the condenser, it exchanges heat with the steam discharged from the steam turbine to condense the steam. The gasified carbon dioxide enters the compressor to be compressed in...

Embodiment 2

[0035] In this embodiment, the liquid carbon dioxide cooling medium is obtained by separating and compressing the boiler flue gas, continue to refer to figure 1 , on the basis of the system described in Embodiment 1, a boiler and a carbon dioxide separation device are also provided, the steam turbine also includes a steam turbine inlet, and the compressor also includes a second compressor inlet; the boiler includes a flue gas exhaust port and a hot steam outlet, the hot steam outlet is connected to the steam turbine inlet, and the flue gas exhaust port is used to discharge flue gas containing carbon dioxide, and the hot steam passes through the steam turbine through the steam turbine inlet and is discharged from the steam turbine outlet in the form of low-pressure steam; The carbon dioxide separation device includes a carbon dioxide separation inlet and a carbon dioxide separation outlet, the carbon dioxide separation inlet is connected to the flue gas exhaust port; the carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com