Preparation method and application of three-dimensional cubic CeO2/Mn2O3 composite photo-thermal catalyst

A three-dimensional cubic, catalyst technology, used in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., to achieve high redox activity, improved purity, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A three-dimensional cubic CeO 2 / Mn 2 o 3 A method for preparing a composite photothermal catalyst, comprising the steps of:

[0033] S100. Dissolve 22.5g of cerium nitrate hexahydrate and 9.3g of urea in 60ml of deionized water, and stir thoroughly to obtain a mixed solution I;

[0034] Transfer the mixed solution I to a high-pressure reactor, react at 180°C for 16 hours, and separate the white precipitate after cooling;

[0035] The white precipitate was washed and dried to obtain CeO 2 Precursor;

[0036] CeO 2 The precursor was calcined at 400 °C for 4 h in a muffle furnace to obtain mesoporous CeO 2 nano cuboid;

[0037] S200. Dissolve 4.6g of manganous chloride tetrahydrate and 4.5g of urea in 50ml of deionized water, stir thoroughly, and then add 0.04g of mesoporous CeO 2 nanometer cuboid to obtain mixed solution II;

[0038] Transfer the mixed solution II to the autoclave, incubate at 160°C for 12 hours, and separate the beige precipitate after cooling;...

Embodiment 2

[0043] A three-dimensional cubic CeO 2 / Mn 2 o 3 The preparation method of the composite photothermal catalyst adopts the same method as in Example 1, only the mesoporous CeO 2 The addition amount of nanocuboids was changed to 0.2g to obtain three-dimensional cubic CeO 2 / Mn 2 o 3 Composite photothermal catalyst, denoted as CeO 2 / Mn 2 o 3 -2.

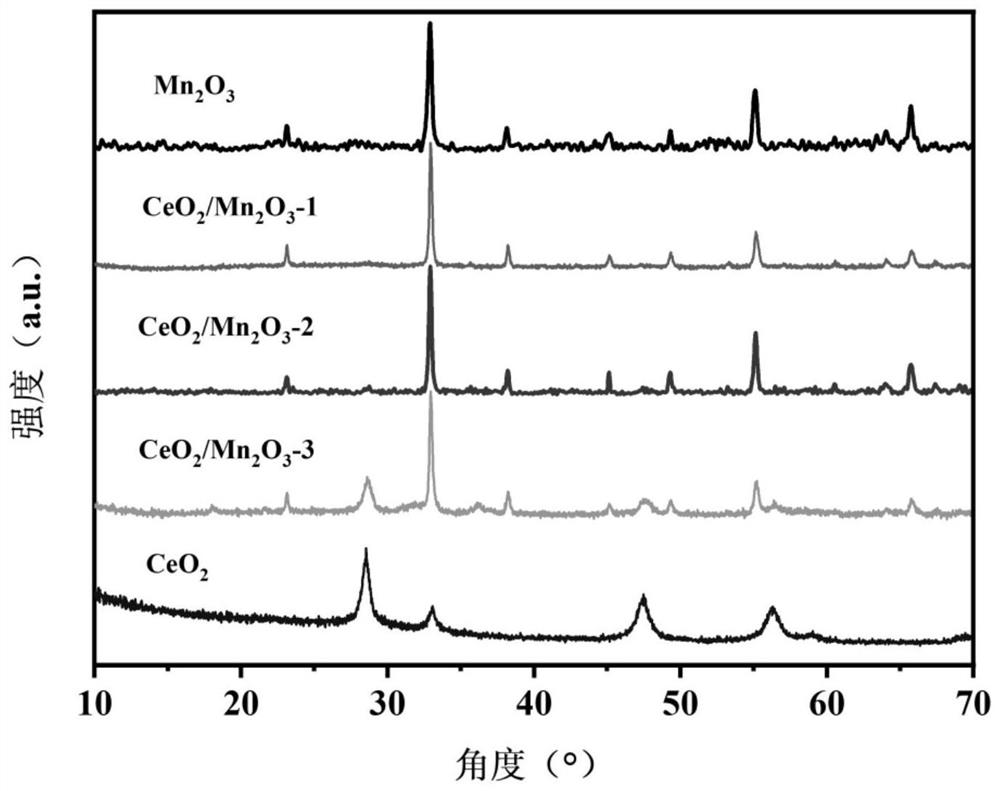

[0044] like figure 1 Shown, CeO 2 / Mn 2 o 3 -2 sample XRD diffraction peak position and Mn 2 o 3 (JCPDS 24-0508) standard peak positions are the same, indicating that Mn in the composite catalyst 2 o 3 The phase did not change; by adding mesoporous CeO 2 Nano cuboid, CeO appears in the XRD pattern 2 XRD diffraction peaks (JCPDS 81-0792), indicating CeO 2 / Mn 2 o 3 -2 composite material was successfully prepared, and with the mesoporous CeO 2 With the increase of nanocuboid dosage, CeO 2 The intensity of the XRD diffraction peak increases with the increase, indicating that the CeO 2 / Mn 2 o 3 -2 CeO 2 content i...

Embodiment 3

[0047] A three-dimensional cubic CeO 2 / Mn 2 o 3 The preparation method of the composite photothermal catalyst adopts the same method as in Example 1, only the mesoporous CeO 2 The addition amount of nanocuboid is changed to 0.4g, and the three-dimensional cubic CeO 2 / Mn 2 o 3 Composite photothermal catalyst, denoted as CeO 2 / Mn 2 o 3 -3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com