Technology for preparing all-inorganic perovskite nanocrystals by using high-energy ball milling method

A technology of high-energy ball milling and nanocrystals, applied in the direction of inorganic chemistry, chemical instruments and methods, lead compounds, etc., can solve problems such as complexity, poor product repeatability, and many factors, and achieve simple process flow, reduced Pb content, and wide sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

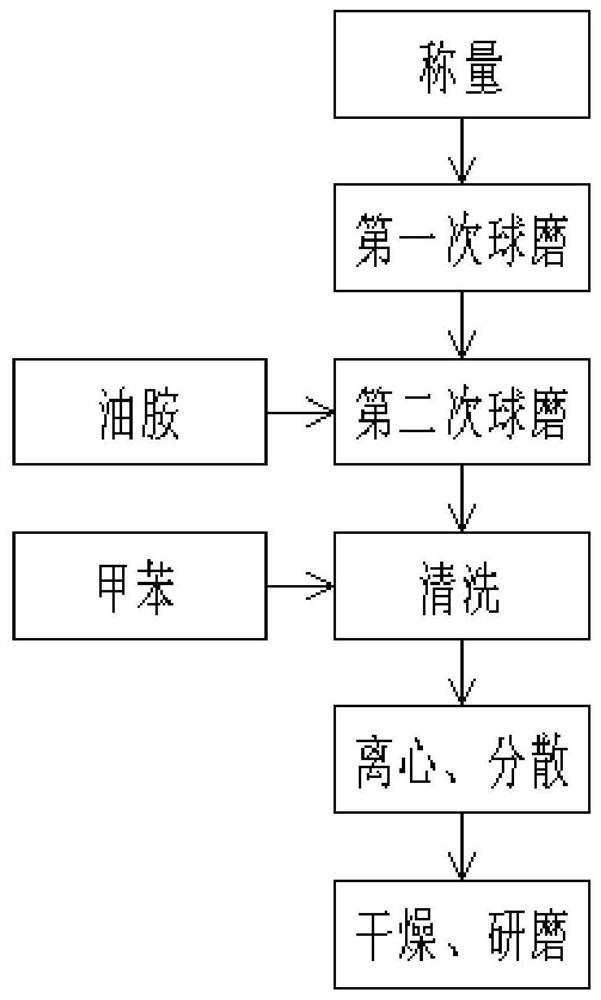

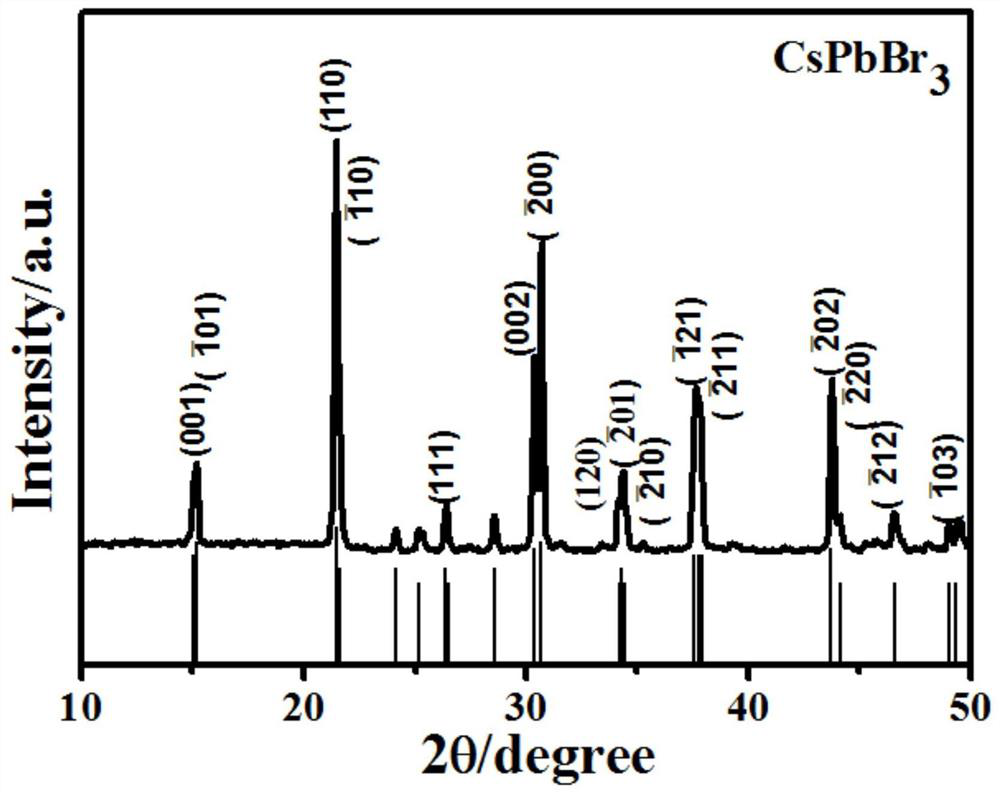

[0043] Such as figure 1 Shown, a kind of technology that utilizes the method for high-energy ball milling to prepare all-inorganic perovskite nanocrystals, the chemical formula of described all-inorganic perovskite nanocrystals is CsPbBr 3 ;

[0044] CbBr 3 The preparation process comprises the following steps:

[0045] 1) Weighing: according to CsPbBr 3 The chemical formula of weighing raw material CsBr, PbBr 2 , CsBr, PbBr 2 Weigh 5 mmol in average; the weighed raw materials are vacuum-dried at 60° C. for 1 to 2 hours.

[0046] 2) The first ball mill: the weighed CsBr, PbBr 2 Put it into a ball mill jar, add grinding balls (the ratio of ball to material is 3.5:1) to carry out the first ball mill; the ball mill time of the first ball mill is 5min, and the ball mill speed is 1000rpm.

[0047] 3) The second ball milling: after the first ball milling, add 0.4mL oleylamine into the ball milling tank and then carry out the second ball milling; the milling time of the second...

Embodiment 2

[0055] A process for preparing all-inorganic perovskite nanocrystals by means of high-energy ball milling, wherein the chemical formula of the all-inorganic perovskite nanocrystals is CsPb 2 Br 5 ;

[0056] According to the step 1) of embodiment 1) to step 6) preparation obtains CsPbBr 3 Nanocrystalline finished product, the CsPbBr 3 The nanocrystalline finished product was soaked in water for 8 hours, transferred to a centrifuge tube for centrifugation; after centrifugation, the supernatant was discarded, and the obtained precipitate was vacuum-dried and ground to obtain CsPb 2 Br 5 Nanocrystalline finished product.

[0057] The CsPb that this embodiment obtains 2 Br 5 The fluorescence quantum yield of nanocrystals is 92%.

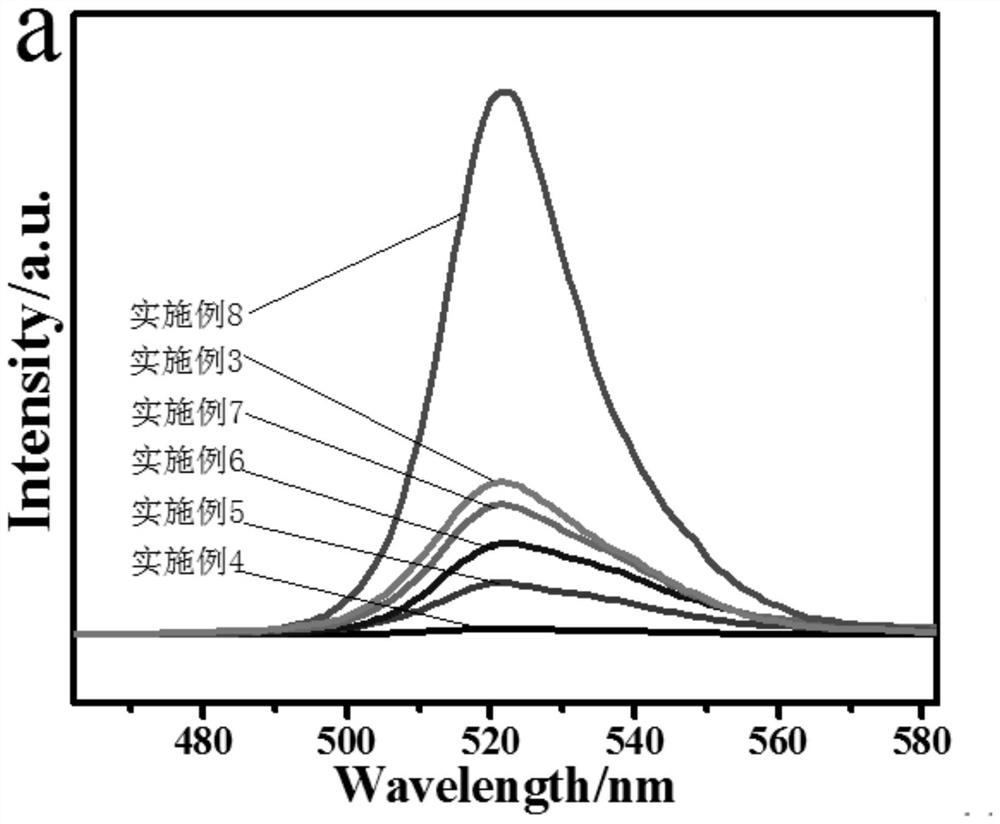

Embodiment 3

[0059] A process for preparing all-inorganic perovskite nanocrystals by means of high-energy ball milling, the chemical formula of the all-inorganic perovskite nanocrystals is CsPbBr 3 ;

[0060] CbBr 3 The preparation process comprises the following steps:

[0061] 1) Weighing: according to CsPbBr 3 The chemical formula of weighing raw material CsBr, PbBr 2 , CsBr, PbBr 2 Weigh 5 mmol in average; the weighed raw materials are vacuum-dried at 60° C. for 1 to 2 hours.

[0062] 2) The first ball mill: the weighed CsBr, PbBr 2 Put it into a ball mill jar, add grinding balls (the ratio of ball to material is 3.5:1) to carry out the first ball mill; the ball mill time of the first ball mill is 5min, and the ball mill speed is 1000rpm.

[0063] 3) The second ball milling: after the first ball milling, add 0.5mL oleylamine into the ball milling tank and then carry out the second ball milling; the milling time of the second ball milling is 20min, and the ball milling speed is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com