Liquid crystal polymer film for flexible copper-clad plate applied to 5G communication and preparation method of liquid crystal polymer film

A technology of liquid crystal polymers and flexible copper clad laminates, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor mechanical properties of products, difficult control of molding processing technology, etc., and achieve the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned liquid crystal polymer film for 5G communication flexible copper clad laminate comprises the following steps:

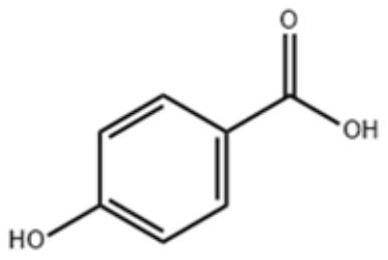

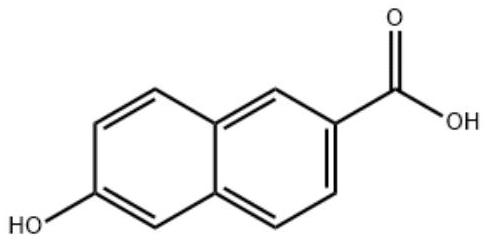

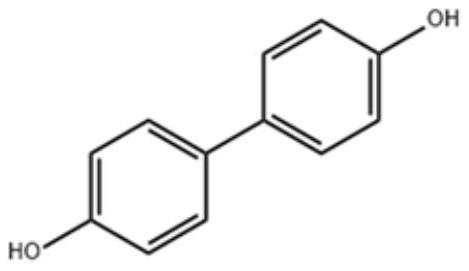

[0048] S1: The monomer p-hydroxybenzoic acid, 6-hydroxy-2-naphthoic acid, biphenol, biphenyl dicarboxylic acid, octafluoro-4,4′-biphenol, acetylating reagent acetic anhydride, catalyst 4-di Aminopyridine and antioxidant tin powder are thrown into a Hastelloy polymerization kettle for prepolymerization to obtain a prepolymer;

[0049] S2: The prepolymer is discharged from the Hastelloy kettle, crushed, and solid-state polycondensed in a nitrogen atmosphere to obtain a liquid crystal polymer;

[0050] S3: Extrude and cast the prepared liquid crystal polymer through a screw extruder, exhaust, melt and plasticize it through a T-die to a cooling roll to obtain a primary liquid crystal polymer film;

[0051] S4: laminating, stretching, and winding the nascent liquid crystal polymer film to obtain a finished liquid cryst...

Embodiment 1

[0063] According to the ratio of 1# monomers, p-hydroxybenzoic acid, 6-hydroxy-2-naphthoic acid, biphenyldiphenol, biphenyldicarboxylic acid, octafluoro-4,4′-biphenol, 4-p-hydroxybenzoic acid, 6 -Hydroxy-2-naphthoic acid, biphenol, acetic anhydride with 1.2 times the total molar number of hydroxyl groups in octafluoro-4,4'-biphenol, 4-dimethylaminopyridine accounting for 100ppm of the total weight of the five monomers, Put tin powder accounting for 0.2% of the total weight of the five monomers into the Hastelloy polymerizer and keep it at 130°C for 2h; raise the temperature to 310°C at a rate of 0.4°C / min and keep it warm for 1h; pour 0.2MPa nitrogen into the polymerizer , the prepolymer is discharged through an 8-hole discharge valve with a diameter of 2mm, crushed, passed through a 20-mesh sieve, and dried at 120°C for 1 hour to obtain a prepolymer;

[0064] The prepared prepolymer was subjected to solid-state polycondensation in a rotary kiln at 195°C for 12 hours under the...

Embodiment 2

[0069] The difference from Example 1 is that p-hydroxybenzoic acid, 6-hydroxy-2-naphthoic acid, biphenyldiphenol, biphenyldicarboxylic acid, octafluoro-4,4'-biphenol , Acetic anhydride accounting for 1.4 times the total molar number of hydroxyl groups in p-hydroxybenzoic acid, 6-hydroxy-2-naphthoic acid, biphenol, and octafluoro-4,4'-biphenol, accounting for 130ppm of the total weight of the five monomers The 4-dimethylaminopyridine and tin powder accounting for 0.22% of the total weight of the five monomers were put into the Hastelloy polymerization kettle and kept at 135°C for 3h; the temperature was raised to 315°C at a rate of 0.5°C / min and kept for 2h; Pour 0.3MPa nitrogen into the polymerization kettle, release the prepolymer through an 8-hole discharge valve with a diameter of 2mm, crush it, pass through a 20-mesh sieve, and dry it at 125°C for 2 hours to obtain a prepolymer; Under the protection of nitrogen, solid-state polycondensation was carried out in a rotary kiln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com