Treatment method of ethyl chloroformate rectifying still residues

A technology of ethyl chloroformate and treatment method, which is applied in the field of waste treatment in chemical production, and can solve the problems of not providing phosgene treatment scheme and low quality of diethyl carbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

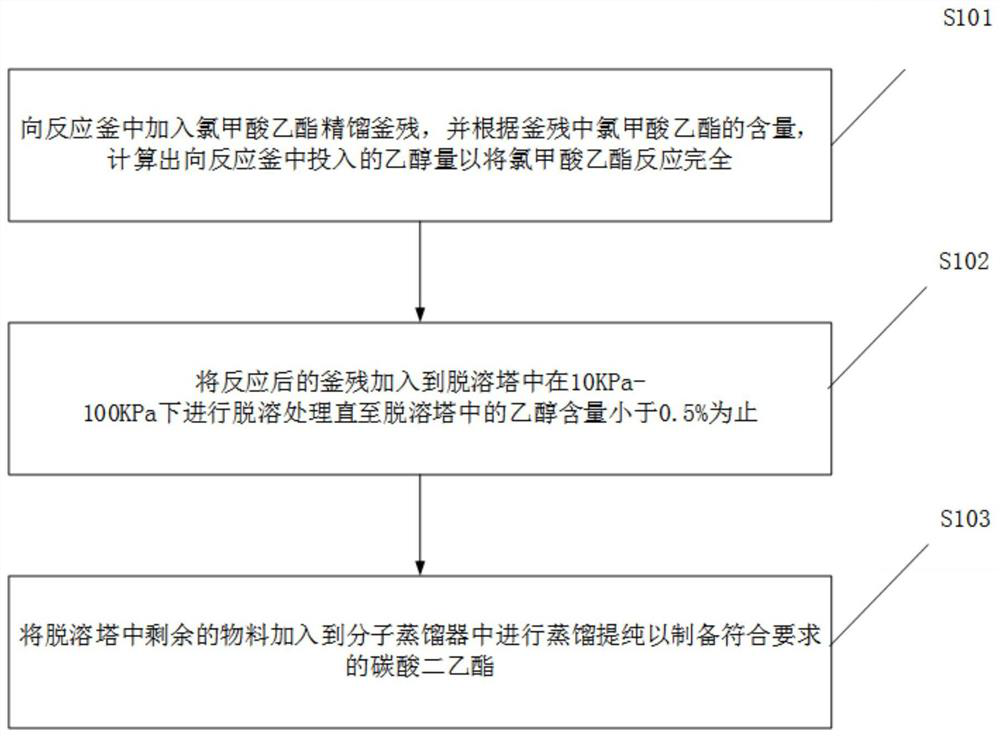

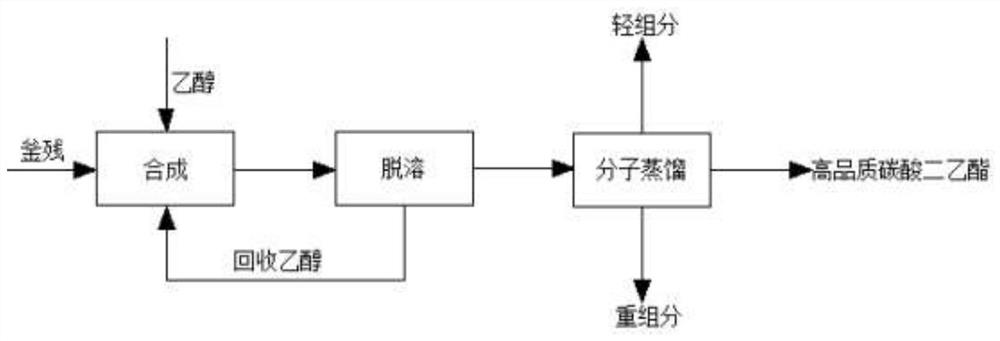

Method used

Image

Examples

Embodiment 1

[0035] To the 500L reactor, oxycetate is 300 kg of chloroformate, 45kg of ethyl chloroformate, stirring, and 38.33 kg of anhydrous ethanol, ethanol and othyl chloroformate, to 2: 1. The temperature rose to 60 ° C, the reaction time is 5h. The synthesis liquid was removed under 10 kPa, and the top of the column was removed and a small amount of light components, and the top of the column was substantially uncondensation, and the ethanol content of the tower is 0.2%. The tower is distilled into the molecular distiller at a certain speed, and the light component, the diethyl carbonate primary fraction and the recombination are collected. The molecular distillation apparatus is 10 Pa, the temperature is 80 ° C, the material residence time is 30s; the diethyl carbonate is 99.97%, and the remaining indicators satisfy the high-pure level quality index, the diethyl carbonate is 85.2%.

Embodiment 2

[0037]In Example 1 was investrated in Example 1 in Example 1 300 kg (lower), 25kg of chloroformate, mixed with ethyl chloroformate, stirred, and 0.2 kg of anhydrous ethanol, ethanol and chloroform acid. Ethyl ester mol ratio was 1: 1; heated to 70 ° C, the reaction time was 8 h. The synthesis liquid was removed under 100 kPa, and a small amount of light components were taken to the top of the tower, and the tower is basically uncondensible, and the ethanol content of the tower is 0.05%. The tower is distilled into the molecular distiller at a certain speed, and the light component, the diethyl carbonate primary fraction and the recombination are collected. The molecular distillation device is vacuum having a vacuum having a temperature of 70 ° C, and the material residence time is 100 s; the diethyl carbonate is 99.95%, and the remaining index satisfies the quality index requirements of excellent quality, the diethyl carbonate yield is 80.3%.

Embodiment 3

[0039] In Example 1 in Example 1 was 300 kg of ethyl chloroformate in Example 1, 45 kg of ethyl chloroformate was converted, and 192 kg of anhydrous ethanol was added to the kettle, ethanol and chloroformate MOL ratio. 10: 1; heated to 80 ° C, the reaction time was 4 h. The synthesis liquid was removed under 20 kPa, and the top of the tower was subjected to excess ethanol and a small amount of light components, and the top of the tower was basically removed, and the ethanol content of the tower was 0.13%. The tower is distilled into the molecular distiller at a certain speed, and the light component, the diethyl carbonate primary fraction and the recombination are collected. The molecular distillation apparatus is vacuum is 20 Pa, temperature 90 ° C, the material residence time is 200 s; the primary fraction of diethyl carbonate is 99.99%, and the remaining index satisfies the electronic level mass index requirements, the diethyl carbonate yield is 83.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com